Robot rotating base

A technology of robots and reducers, applied in the field of robots, can solve the problems of poor load-bearing capacity, short service life of cables, and poor rigidity of the swivel structure, and achieve the effects of clear cable arrangement, improved stability and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

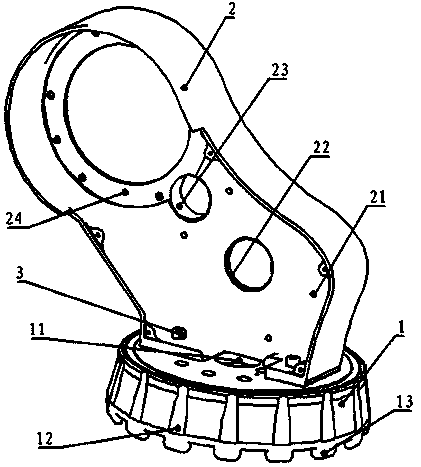

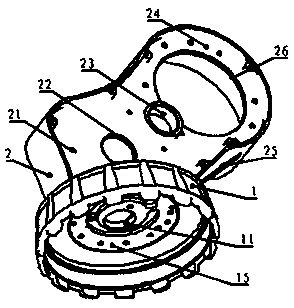

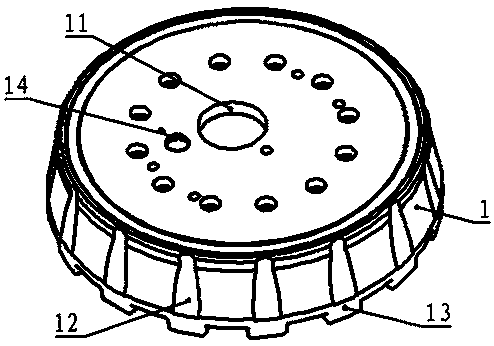

[0016] As shown in the figure, a robot swivel seat, the first shaft part 1 and the second shaft part 2 are fixedly connected by bolts 3; the upper end of the first shaft part 1 is provided with a first reducer output end The flange 15 and the threading hole 11 are located in the middle of the first shaft part 1; the second motor mounting hole 21 and the second motor shaft avoidance hole 22 are provided on the lower half of the second shaft part 2; the upper half The second reducer mounting flange 24 and the threading hole III 26 are provided at the top; the threading hole II 23 is located in the middle of the second shaft part 2; by machining the first shaft part 1 and the second shaft part 2 respectively, then Assembled and combined together, this greatly reduces the difficulty of machining, and the cables are introduced from the hollow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com