Forming equipment of PLA dual spraying film paper tableware

A technology for forming equipment and tableware, which is applied in the manufacture of papermaking, paper/cardboard containers, and rigid/semi-rigid containers. Improve the quality, ensure the quality, avoid the obvious effect of knurling emergency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

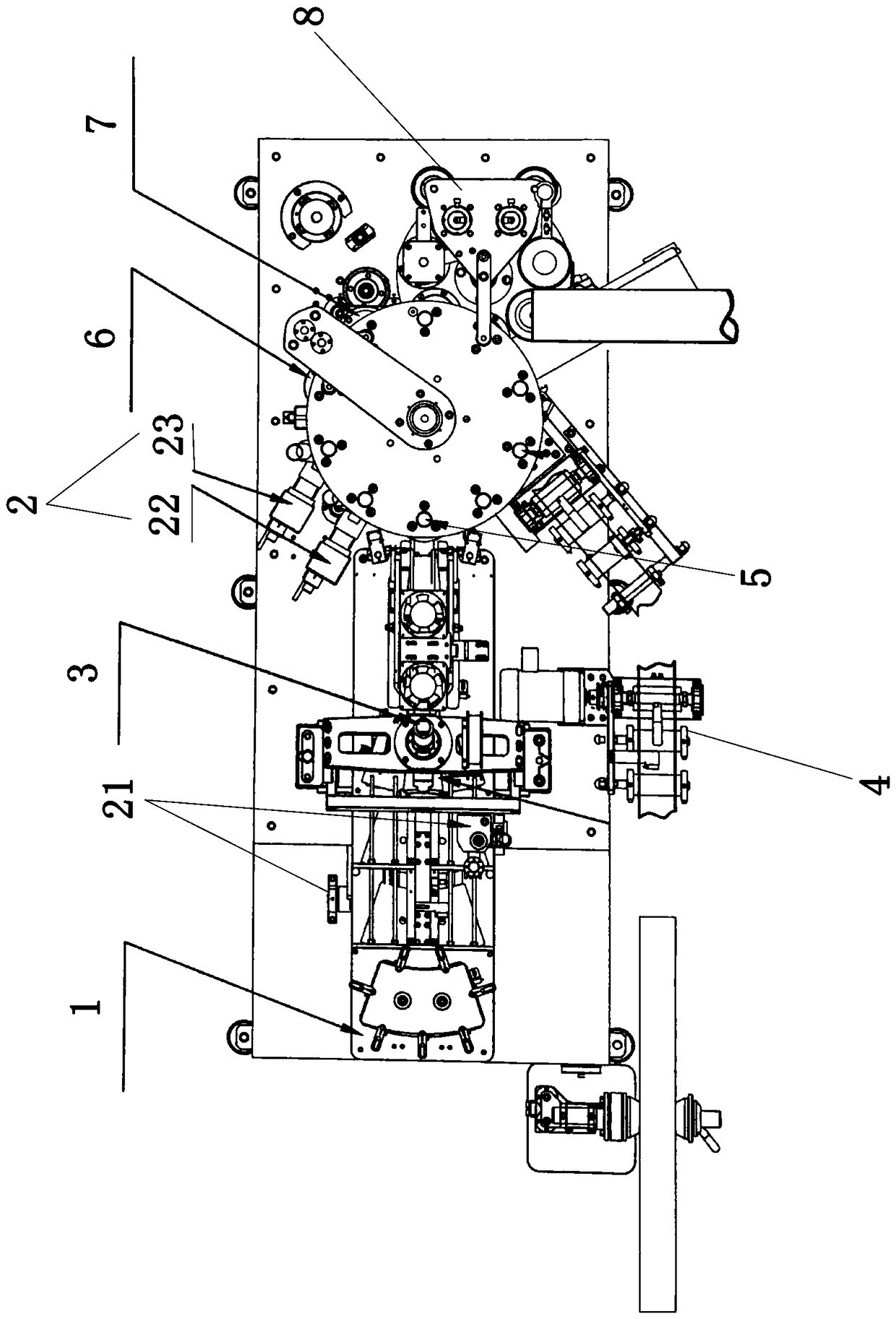

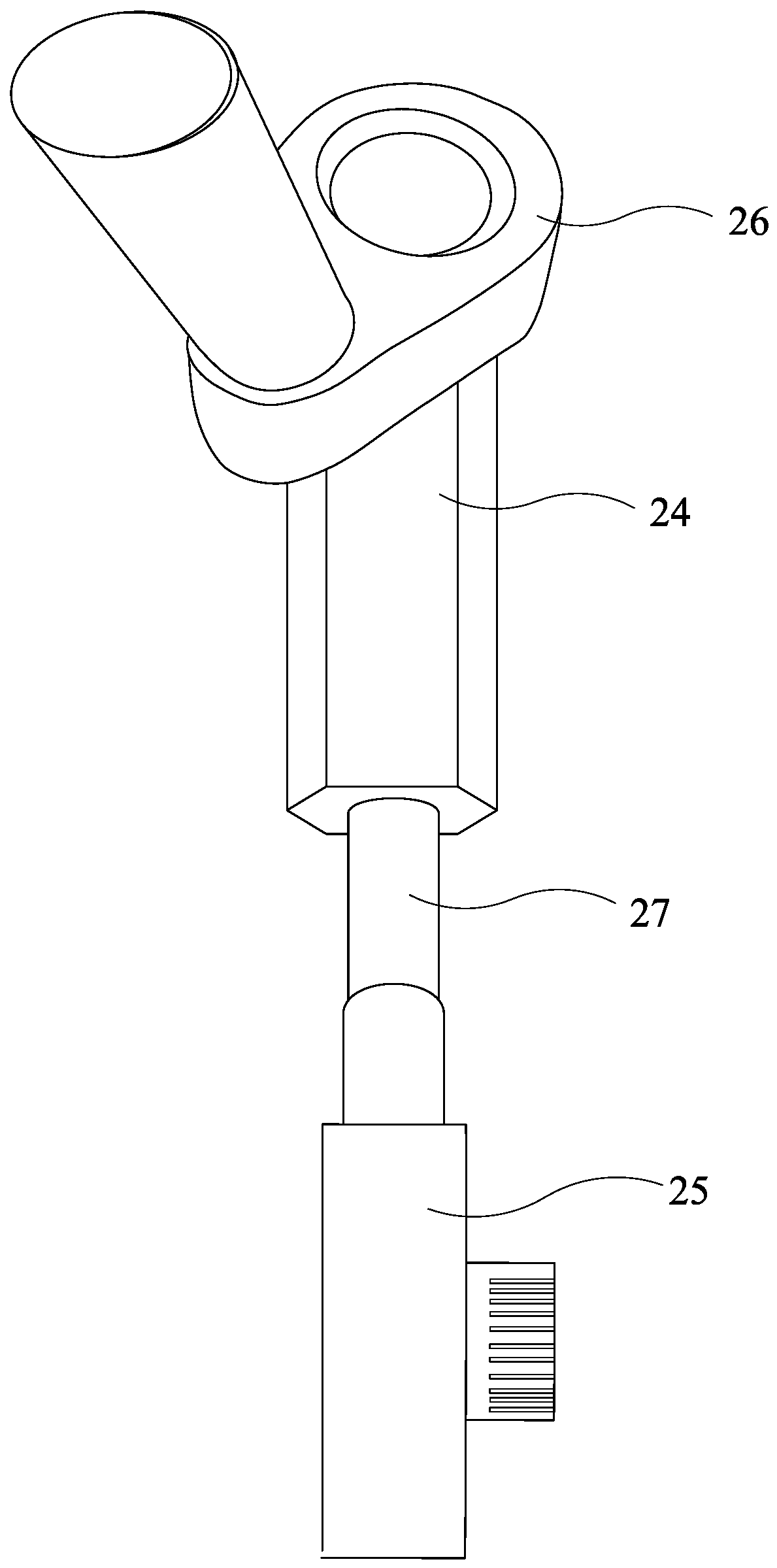

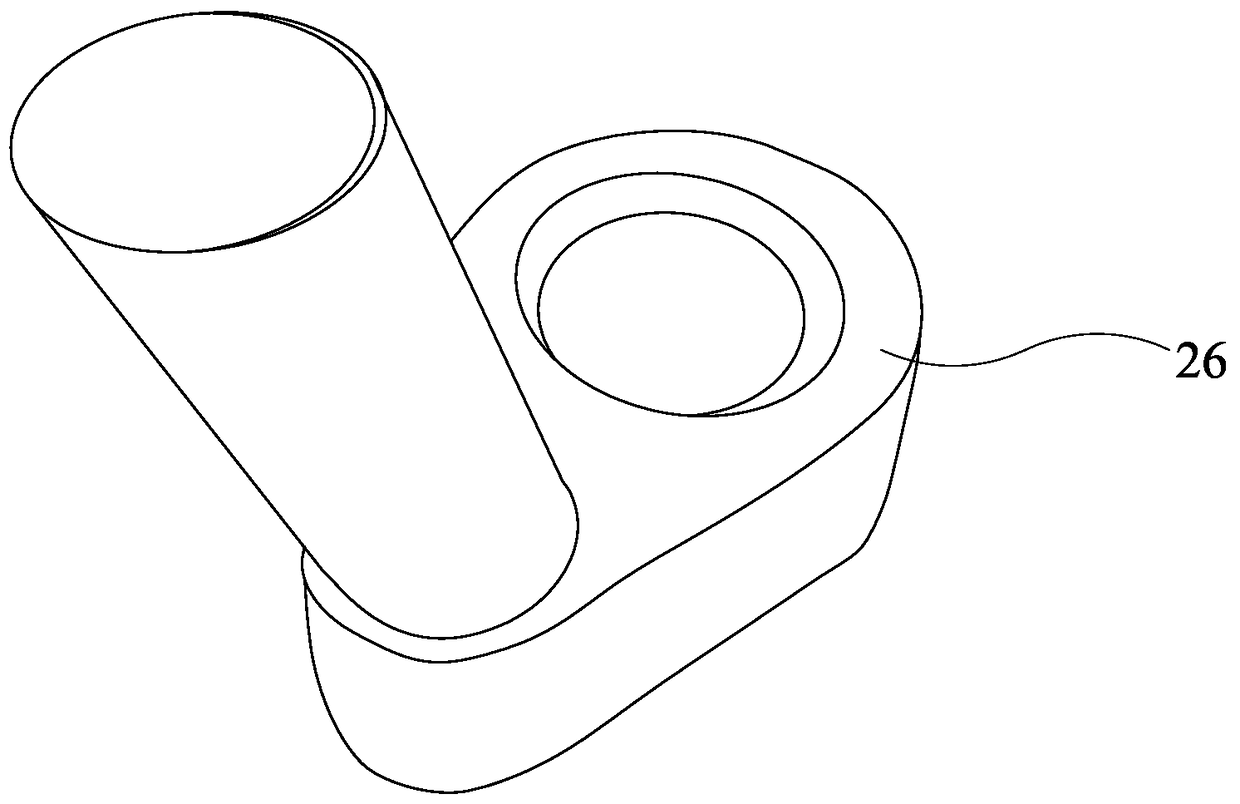

[0039] Such as figure 1 As shown, the present invention discloses a molding equipment of PLA double-coated paper tableware, which includes a frame and a paper suction mechanism 1 arranged on the frame, a first hot air heater 21, an ultrasonic heater 3, a bottom feeding Mechanism 4, combination mechanism 5, second hot air heater 22, third hot air heater 23, bottom rolling mechanism 6, cup bottom knurling mechanism 7, cup edge curling mechanism 8.

[0040]When producing PLA double-coated paper tableware such as paper cups, the PLA double-coated paper forming the cup body is sent into the molding equipment through the paper suction mechanism 1, and then the two sides of the PLA double-coated paper are paired by the first hot air heater 21. The side is heated, and after the heating is completed, the two sides of the PLA double-coated paper are bonded by the ultrasonic heater 3 to form a cup body. Then the cup body enters the combination mechanism 5 and is combined with the bottom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com