Steel keel building wall and foundation heat insulation bridge structure and construction method

A technology for building walls and steel keels, which is applied to building components, building structures, and thermal insulation. It can solve problems such as heat loss, complex structures, difficult to consider design requirements for structures, waterproofing, and heat-breaking bridges, etc., to avoid heat loss. The loss, the effect of solving the thermal break bridge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

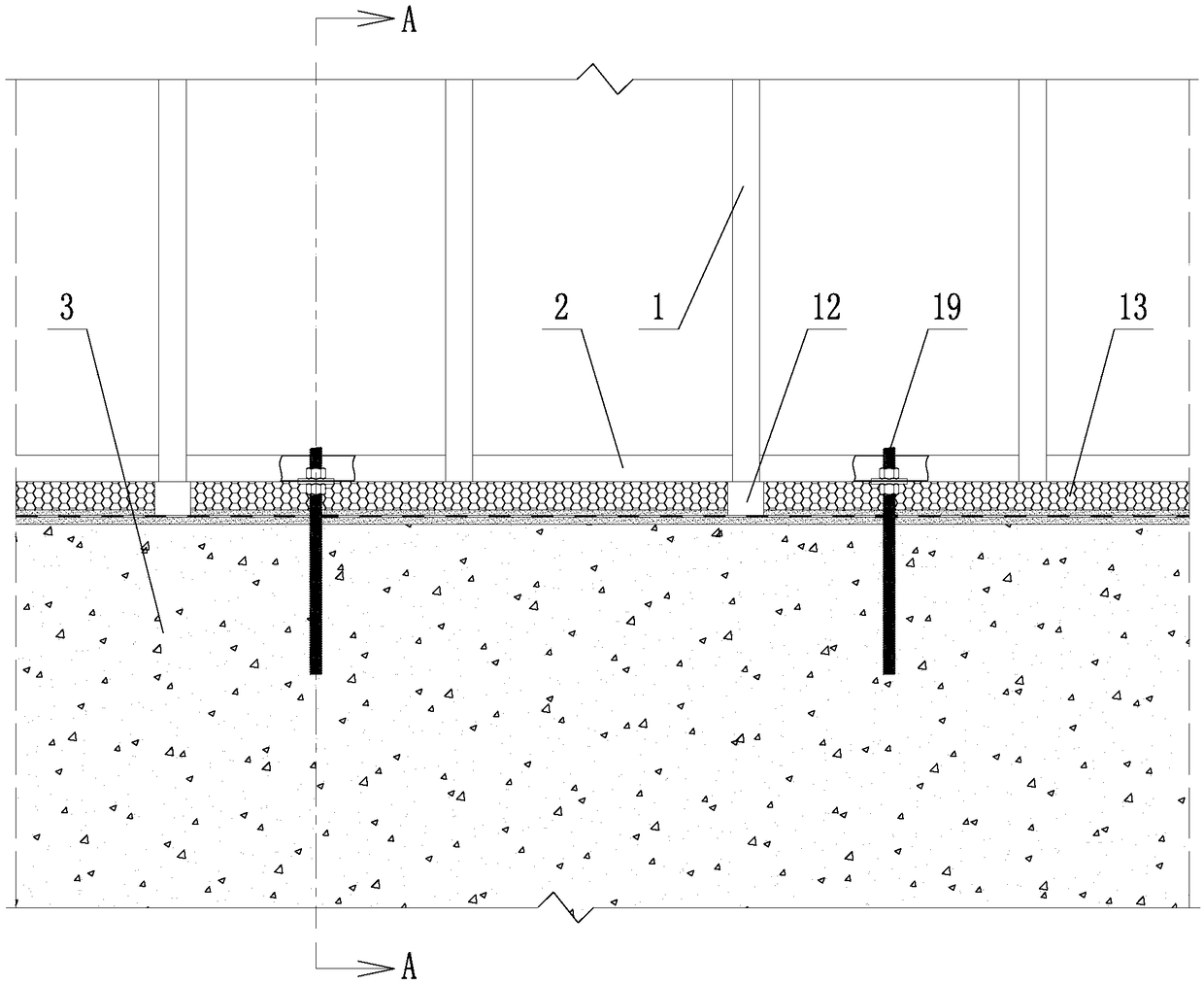

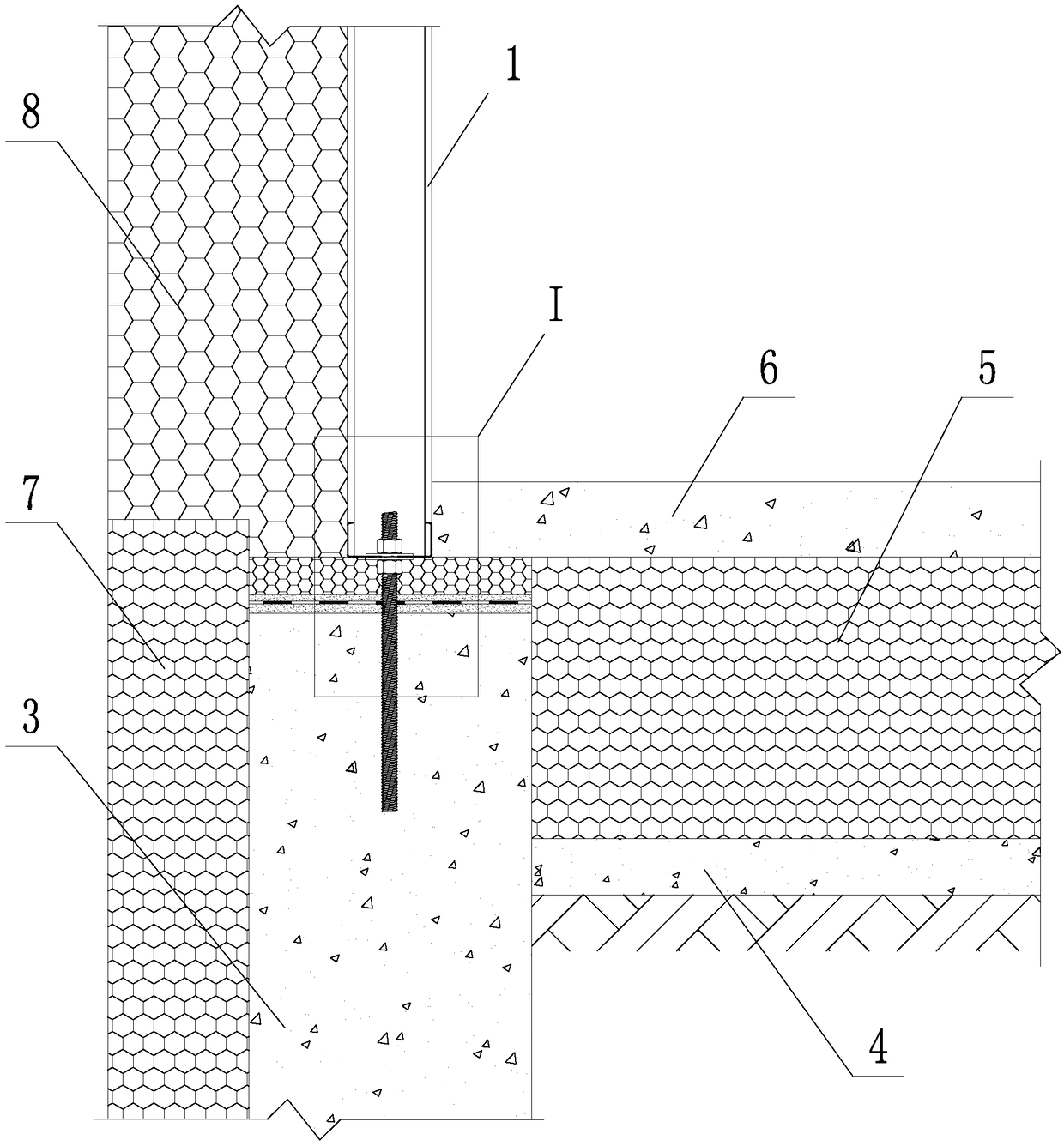

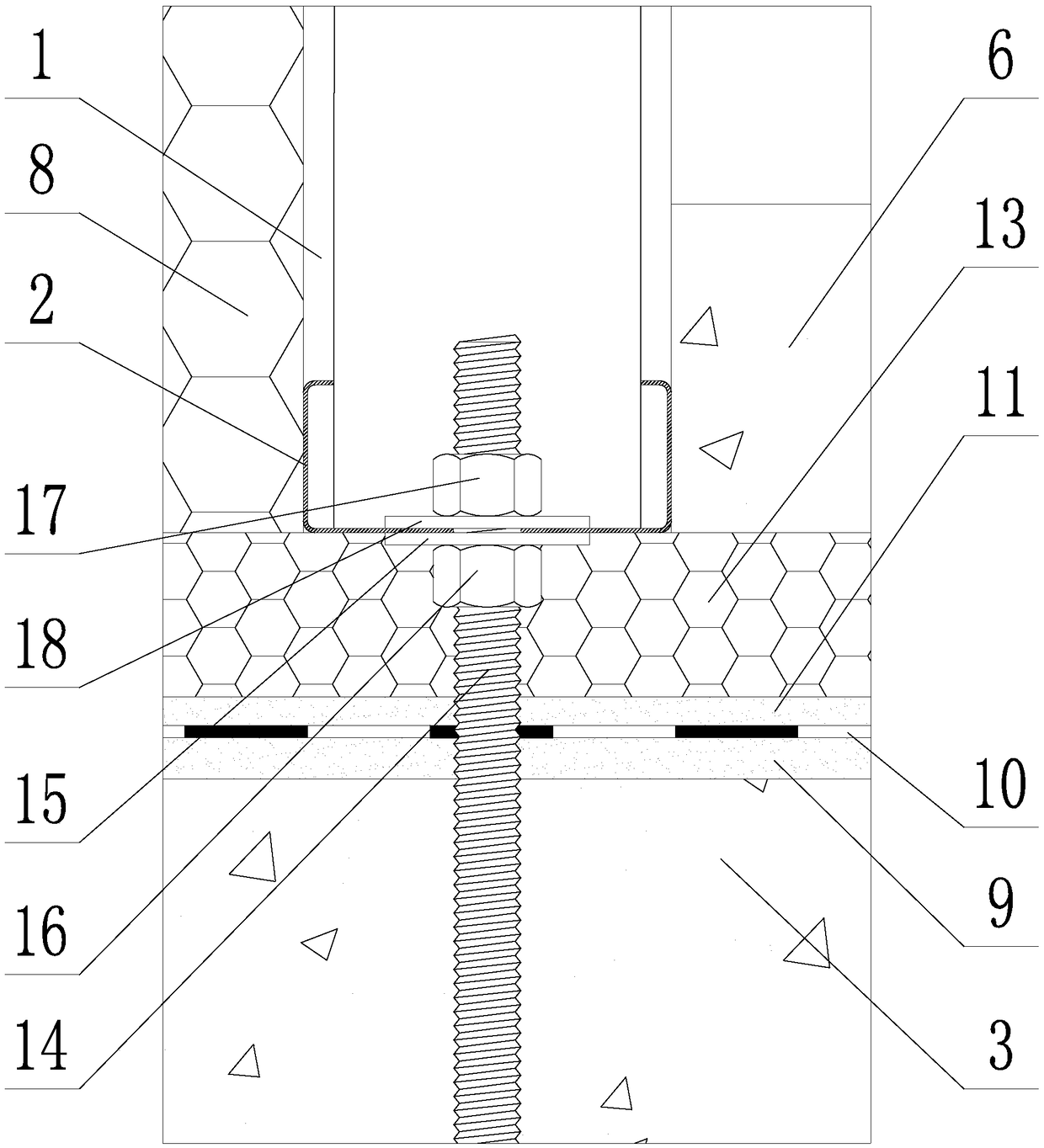

[0035] Such as Figure 1~3 As shown, a thermal insulation bridge structure at the foot of the wall of a steel keel building, including wall steel columns 1, wall steel keel bottom beams 2, foundation walls / beams 3, indoor ground concrete cushion 4, and indoor ground insulation layer 5 , Indoor ground concrete structure layer 6, foundation wall / beam insulation layer 7, wall insulation layer 8, leveling layer 9, moisture-proof / water layer 10, adhesive slurry layer 11, heat-breaking bridge support block 12, heat-breaking bridge insulation The plate 13 and the thermal break bridge bolt connection assembly 19; the wall steel column 1 is fixed on the wall steel keel bottom beam 2, and the wall steel keel bottom beam 2 is connected to the foundation wall / beam through the heat break bridge bolt connection assembly 19 3. The tops are fixedly ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap