Split type bearing piece convenient to install

A convenient installation and split technology, applied in the field of bearing parts, can solve the problems of inability to adapt to the installation shaft, troublesome installation and disassembly, reduce friction coefficient, etc., to reduce the difficulty of daily maintenance, facilitate assembly and disassembly for maintenance, and reduce shaking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

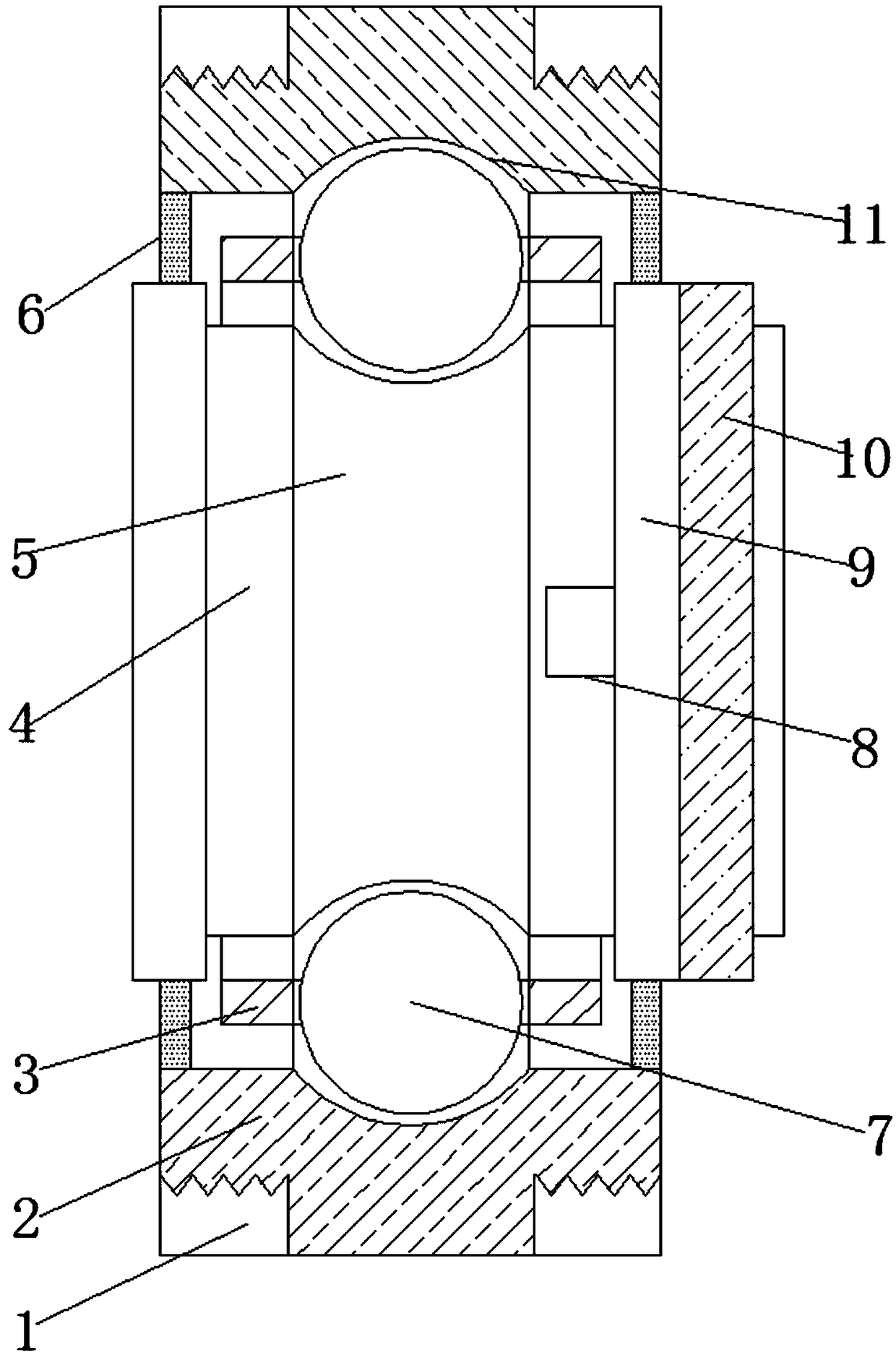

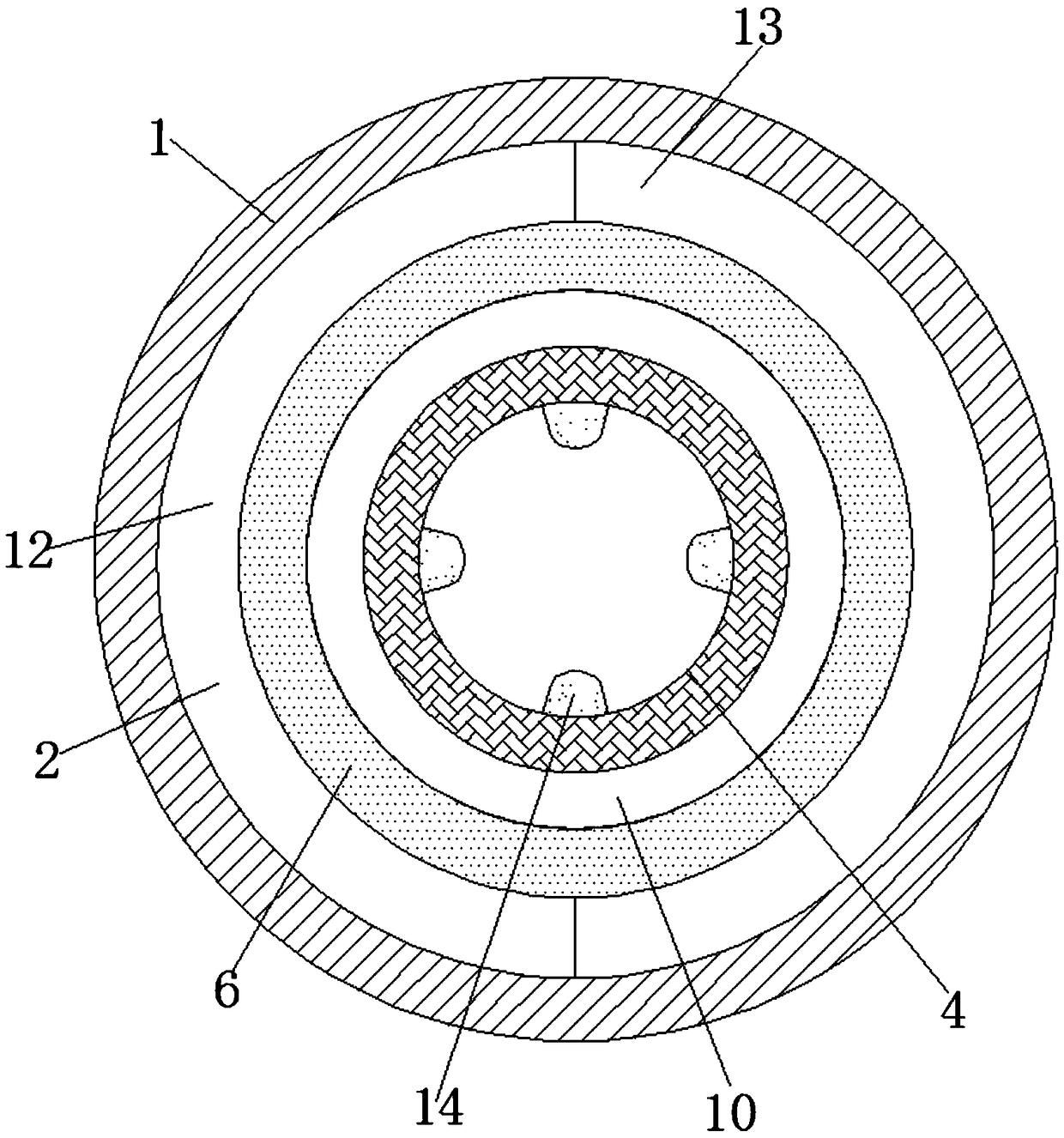

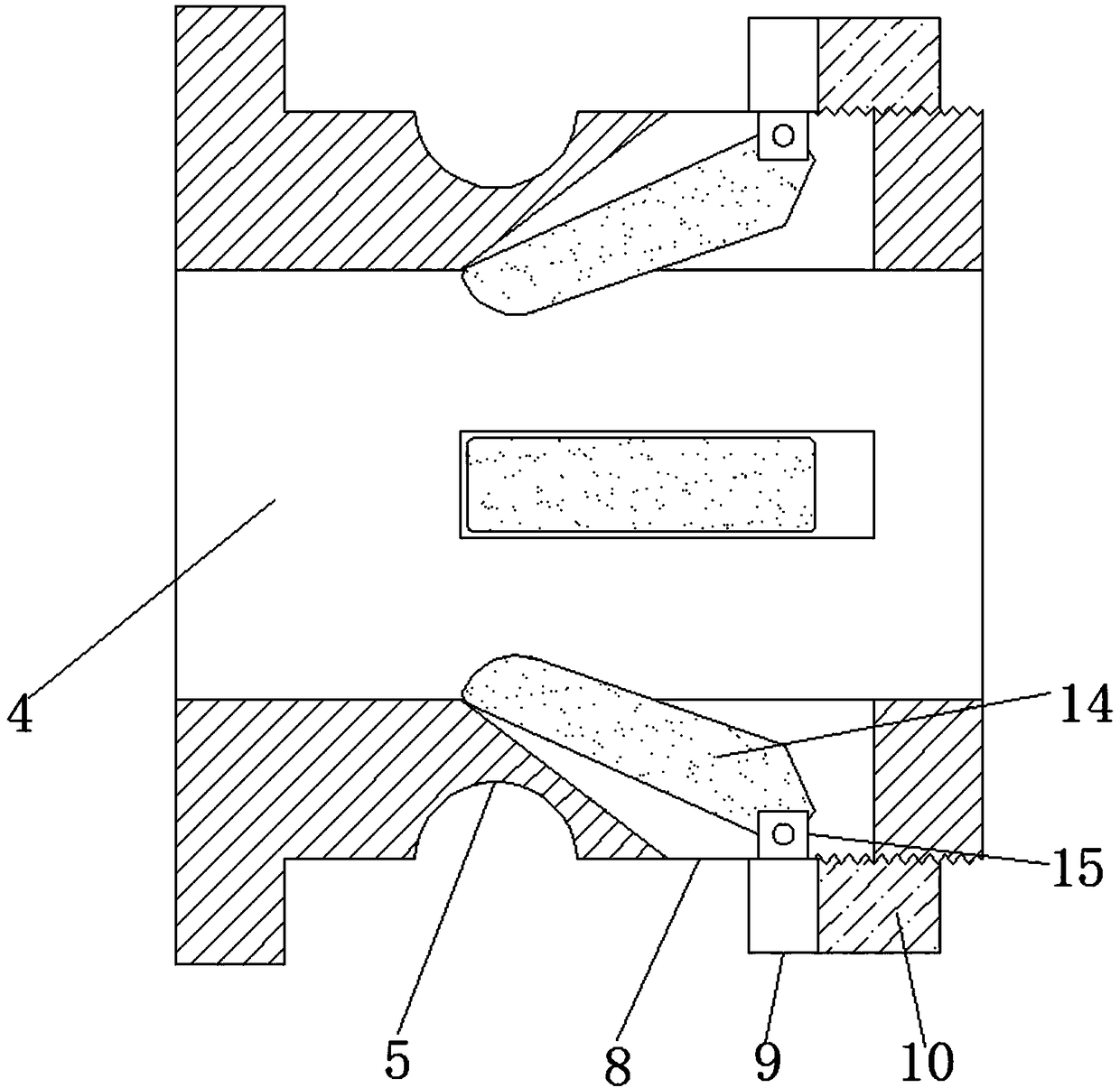

[0020] refer to Figure 1-3 , a split bearing for easy installation, including a lining ring 4, a cage 3 and a bearing outer ring 2, the outer wall of the lining ring 4 is provided with a first groove 5, and the inner wall of the bearing outer ring 2 is provided with a second groove Groove 11, the cage 3 is provided with a pocket hole, and a roller 7 is clamped in the pocket hole, the roller 7 is clamped with the inner wall of the first groove 5 and the second groove 11 respectively, and the end of the lining ring 4 is provided with a limiter. position convex ring, and the side wall of the lining ring 4 away from the end of the limiting convex ring is sleeved with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com