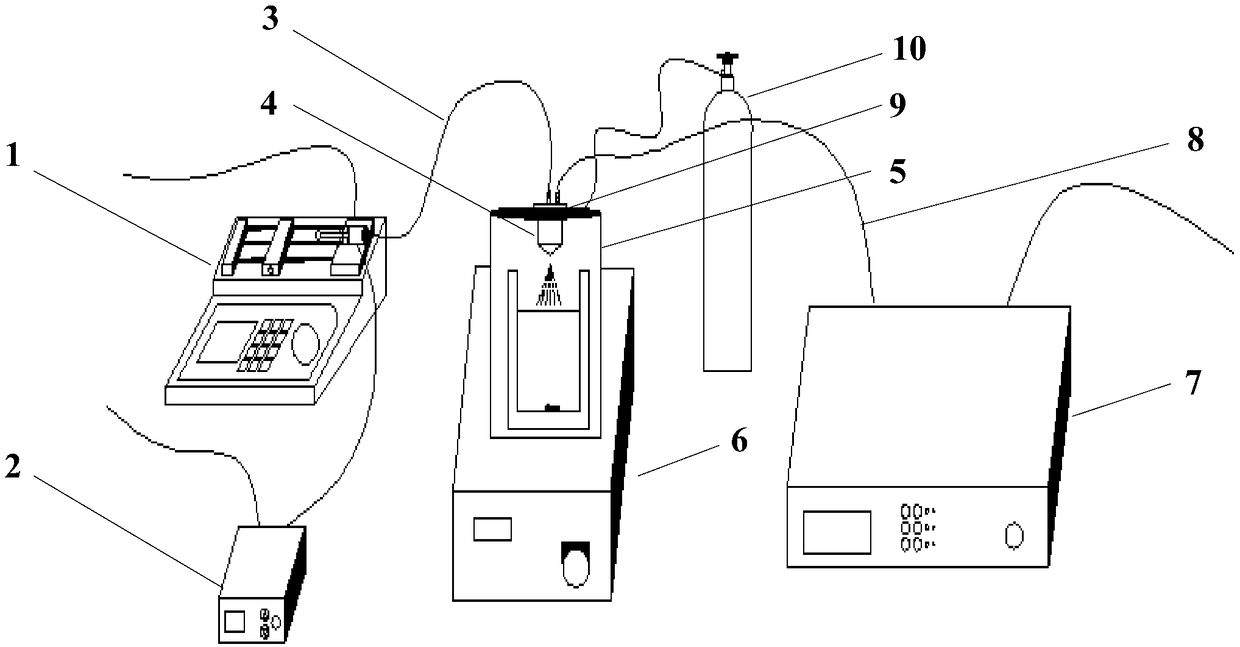

Ultrasonic spray freeze drying device

A spray freeze-drying and ultrasonic technology, used in heating devices, drying solid materials, drying solid materials without heating, etc., can solve the problems of high production cost, long processing cycle of freeze-drying technology, loss of volatile substances, etc. Easy disassembly, good flavor retention, fast spray rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The application of the present invention in the preparation of natural seafood seasoning soup powder. The soup is thawed, homogenized and other pretreatments are carried out. The heating temperature of the heating jacket is 50°C to ensure that the liquid material to be sprayed is sprayed at a temperature of 50°C to ensure that the sprayed liquid material is in a uniform state. The feed flow rate is 5.0mL / min, the ultrasonic power is 3W, and the ultrasonic frequency is 40KHz. The small liquid droplets sprayed by the ultrasonic wave quickly enter the cooling liquid, and are continuously sprayed by the stirring device. The microstructure of the obtained powder is smooth, without gaps and cracks. In the droplets, the protein-rich layer is obtained as a spherical granular product due to this spray freeze-drying, which has the advantages of controllable size, porosity, instant dissolution, good fluidity, and good stability. The ultrasonic spray-freeze drying process helps to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap