Preparing device and method for artificial rock cores

A technology for artificial core and preparation device, which is applied in the direction of measuring device, preparation and sampling of samples for testing, can solve the problems of single size of artificial core preparation and difficulty in core extraction, and reduce manual operation and labor costs. , The overall beautiful and generous, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

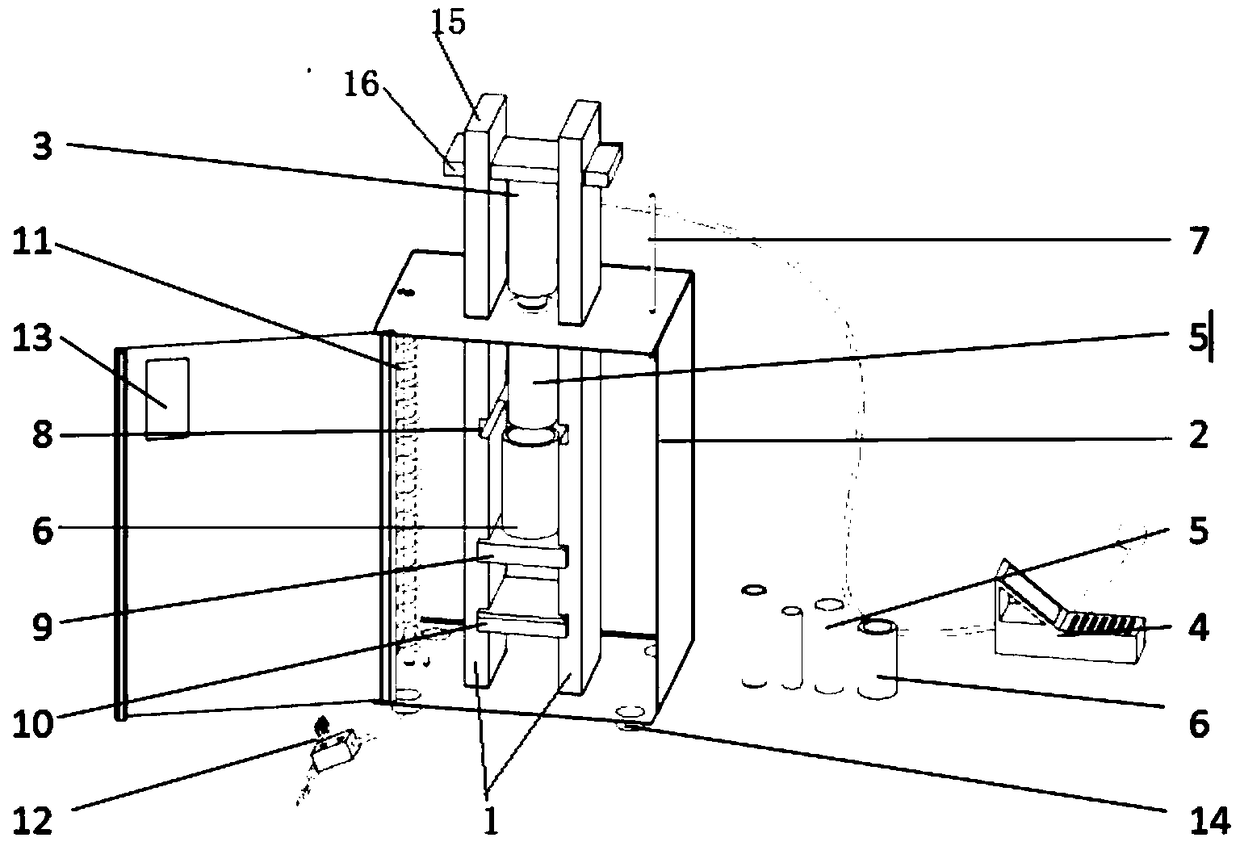

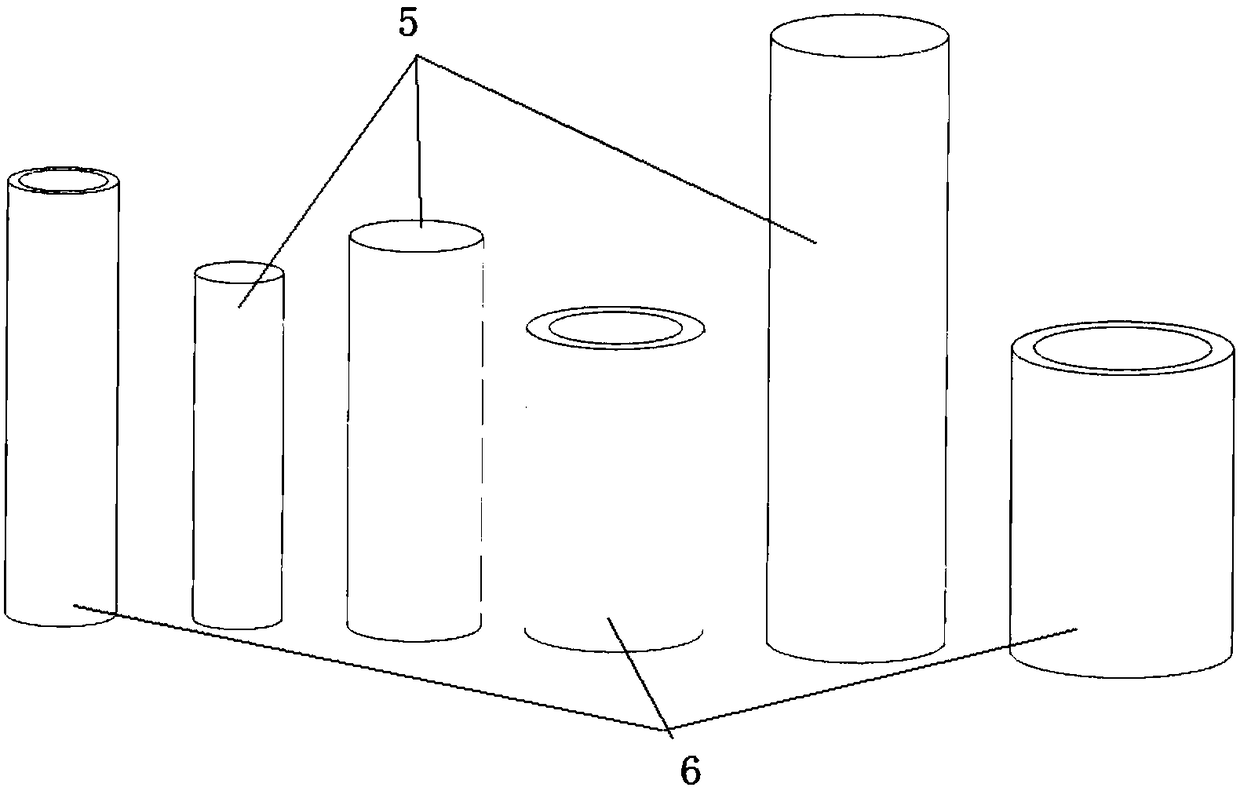

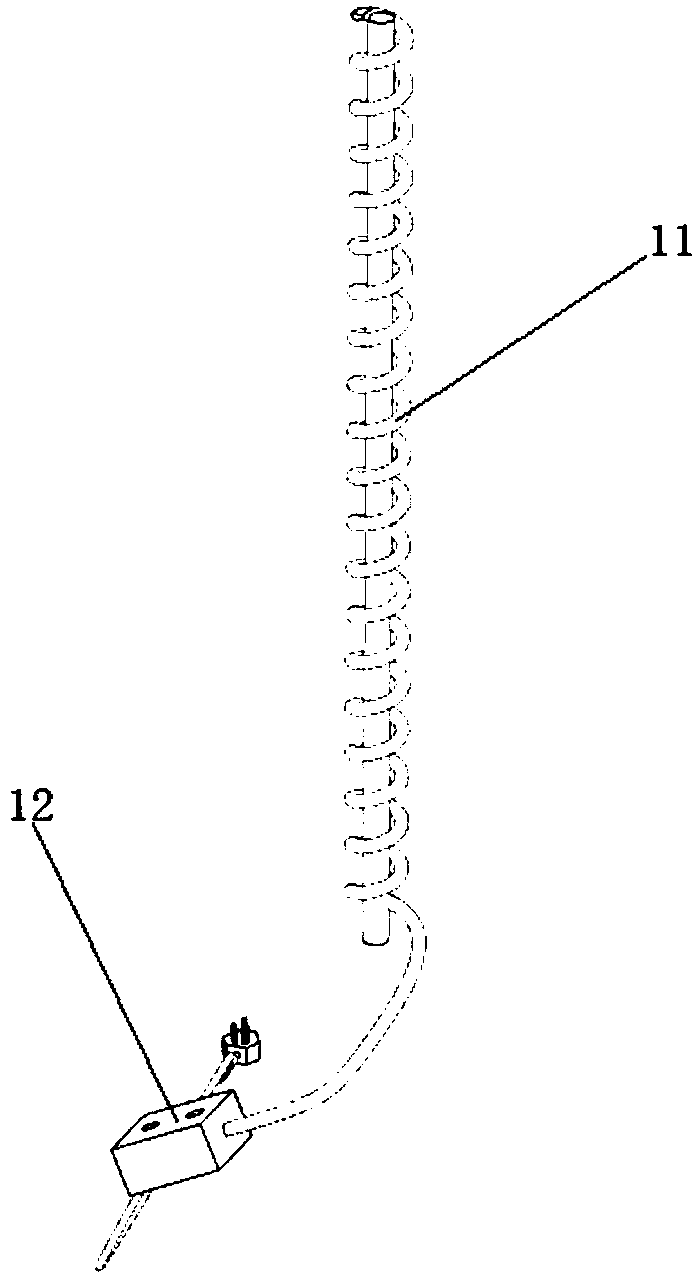

[0030] Such as Figures 1 to 5 As shown, what the present invention relates to is a kind of artificial rock core preparation device and preparation method, includes and comprises two support plates 1, incubator 2, jack 3, drawing instrument 4, pressing plug head 5, pressing mold barrel 6, Thermometer 7, chute 8, pressing stage 9, coring stage 10, temperature control device 11, temperature control plug 12, observation port 13, load-bearing footing block 14. The pressing plug is placed in the inner hole of the pressing mold barrel, and three slide grooves 8 are provided on the two support plates. The operator can select th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com