Heating and digestion automatic control device for detecting heavy metal of foods

An automatic control device, heating and digestion technology, applied in the preparation of test samples, etc., can solve the problems of low quality and efficiency of detection, different degrees of heating and digestion in beakers, no automatic control device, etc., to improve labor intensity and contact environment , Improve the quality and efficiency of detection, and eliminate the effect of human interference factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

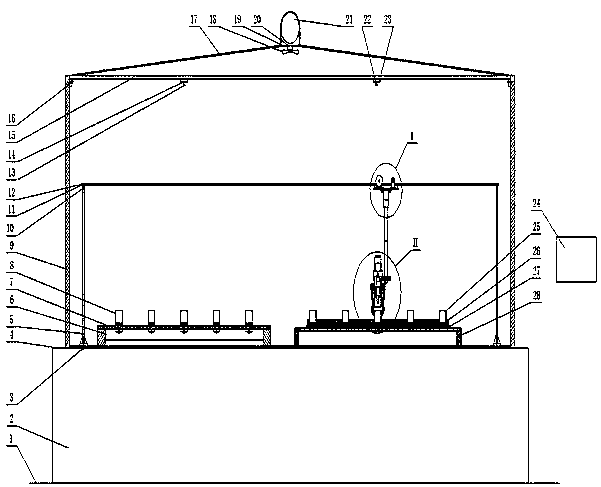

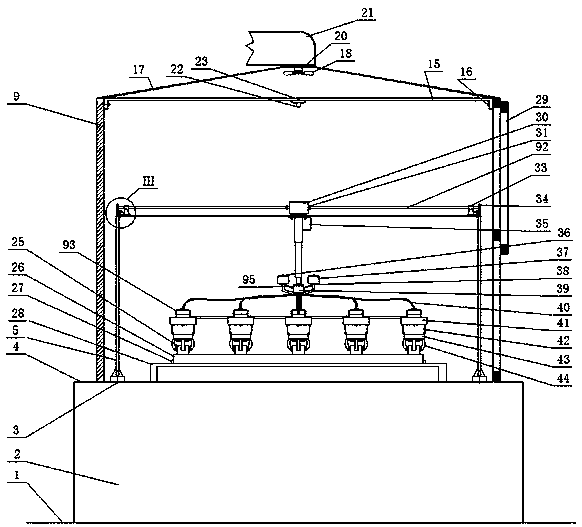

[0021] Accompanying drawing is a kind of specific embodiment of the present invention. A workbench 2 is arranged on the ground 1, and a smoke exhaust box 9 is placed on the workbench 4. In the smoke exhaust box 9, a heating device 6 is placed on one side of the workbench 4 and a height platen 28 is placed on the other side. Two positioning angles 27 are fixedly arranged diagonally on the upper plane of the plate 28, and a positioning pallet 26 can be placed in the two positioning angles 27. The positioning pallet 26 is provided with concave holes for evenly placing the beakers 25, and is placed on the positioning pallet. The height of the beaker 25 and the uniform distance are the same as the height and uniform distance of the beaker 8 placed on the heating device. The beaker 8 placed on the heating device is placed on the heating plate surface 7, facing the bottom surface of the beaker 8 placed on the heating device, that is, the back surface of the heating plate surface 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com