Highly efficient thermoelectric module with multistage temperature adjustment layer

A technology of thermoelectric module and temperature regulation layer, which is applied to thermoelectric devices, thermoelectric devices and circuits that only use the Peltier or Seebeck effect, etc., to achieve the effect of improving the overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will now be further described in conjunction with the embodiments and drawings:

[0027] This embodiment

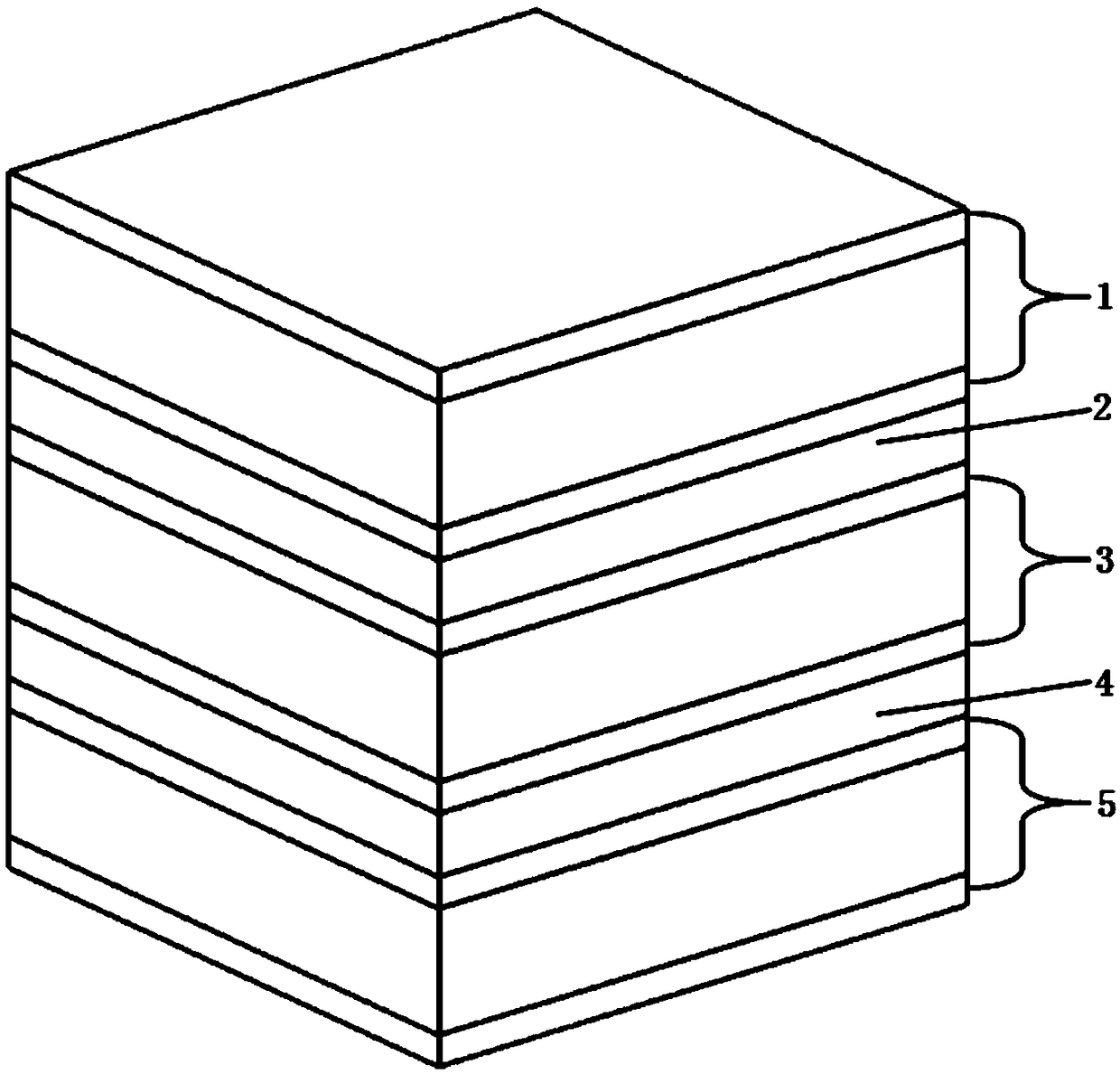

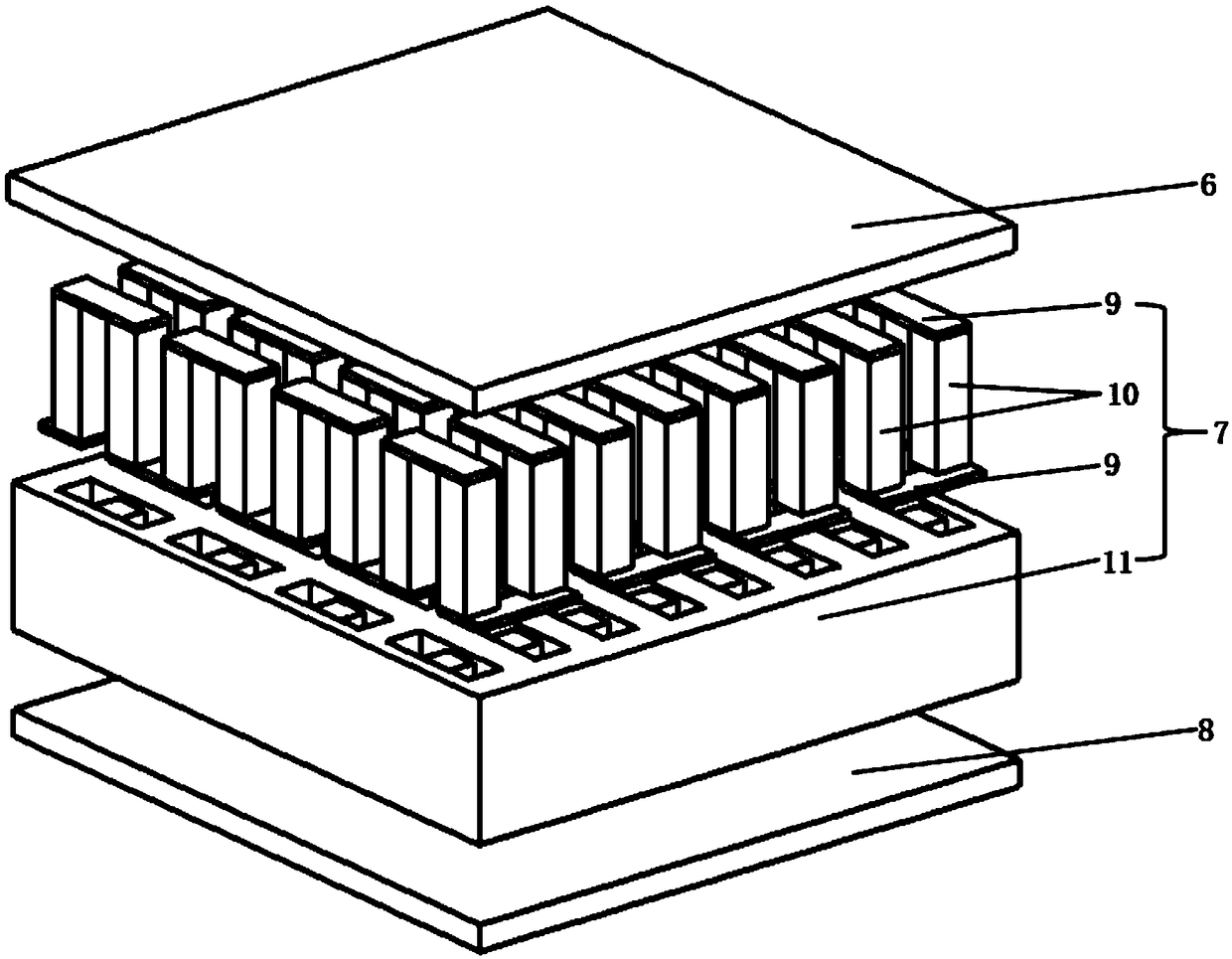

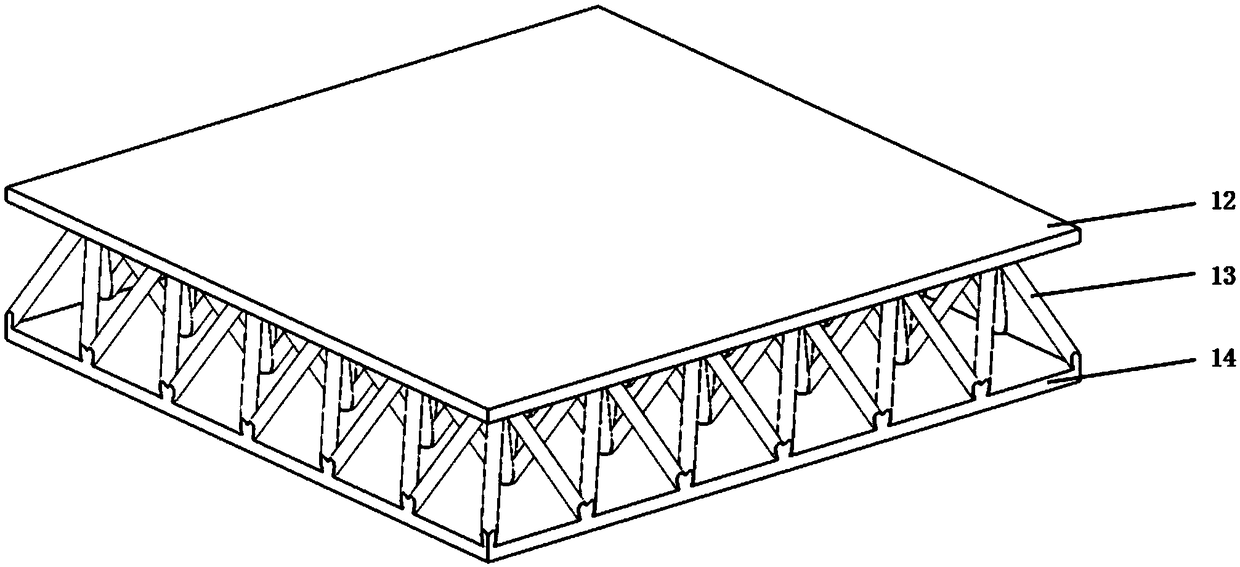

[0028] Including the high temperature layer 1, the middle temperature layer 3, and the low temperature layer 5. There is a high and medium temperature regulating layer 2 between the high temperature layer and the middle temperature layer, and a middle and low temperature regulating layer 4 between the middle temperature layer and the low temperature layer; the high temperature layer 1, the middle temperature layer 3. Each level of the low temperature layer 5 is composed of the upper substrate layer 6, the functional layer 7 and the lower substrate layer 8.

[0029] Preferably, the thermoelectric module adopts a multi-level structure, including three levels of high temperature layer 1, medium temperature layer 3 and low temperature layer 5. From top to bottom, there are high temperature layer 1, high and medium temperature regulation layer 2, medium t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com