High light efficiency microchip laser

A microchip laser, high optical efficiency technology, used in lasers, laser parts, phonon exciters, etc., can solve the problems of laser quenching, low optical efficiency and output power, restricting direct application, etc., to improve output power, High pumping efficiency and improved light efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

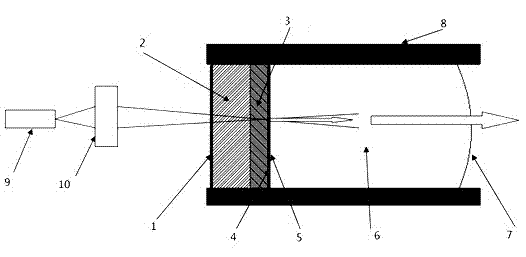

[0025] see first figure 1 , figure 1 It is a schematic structural diagram of Embodiment 1 of the high-efficiency microchip laser of the present invention. It can be seen from the figure that the high-efficiency microchip laser of the present invention includes a pumping light source 9 and a focusing system 10, which are sequentially arranged from left to right along the laser output direction of the pumping light source 9. It is the coupling lens 10, the total reflection cavity film 1, the laser medium 2, the passive Q-switching medium 3, the partial reflection cavity film 4, the first curved surface 5, the amplification medium 6 and the second curved surface 7, in a cylindrical thermal The laser medium 2 and the amplifying medium 6 are sequentially arranged in the 268, and the first curved surface 5 and the second curved surface 7 are two end surfaces of the amplifying medium 6. The first curved surface 5 is a plane, the second curved surface 7 is a spherical surface, R=8mm ...

Embodiment 2

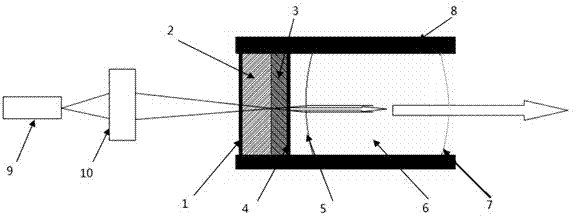

[0028] refer to figure 2 , figure 2 It is a schematic structural diagram of Embodiment 2 of the high optical efficiency microchip laser of the present invention. It can be seen from the figure that the high optical efficiency microchip laser of the present invention includes a pumping light source 9 and a coupling lens 10, which are sequentially arranged from left to right along the laser output direction of the pumping light source 9 It is the coupling lens 10, the total reflection cavity film 1, the laser medium 2, the passive Q-switching medium 3, the partial reflection cavity film 4, the first curved surface 5, the amplification medium 6 and the second curved surface 7, in a cylindrical thermal The laser medium 2 and the amplifying medium 6 are sequentially arranged in the 268, and the first curved surface 5 and the second curved surface 7 are two end surfaces of the amplifying medium 6. The first curved surface 5 is a spherical surface with a radius of curvature R=3mm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com