Display device, manufacturing method thereof, and display device

A display device and electrode packaging technology, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve problems such as low utilization rate, large film-forming area, and complicated process, so as to save usage and reduce costs , Improve the effect of comprehensive mechanical properties

Active Publication Date: 2019-10-01

BOE TECH GRP CO LTD +1

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The general OLED manufacturing process is to deposit the anode, hole injection layer, light-emitting layer, and cathode in sequence, and a diaphragm of a specific film quality must be specially set between individual pixels to separate them, and then the OLED is packaged, which is a complicated process; and the packaging material is coated. During the coating process, the film forming area is large and the utilization rate is low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

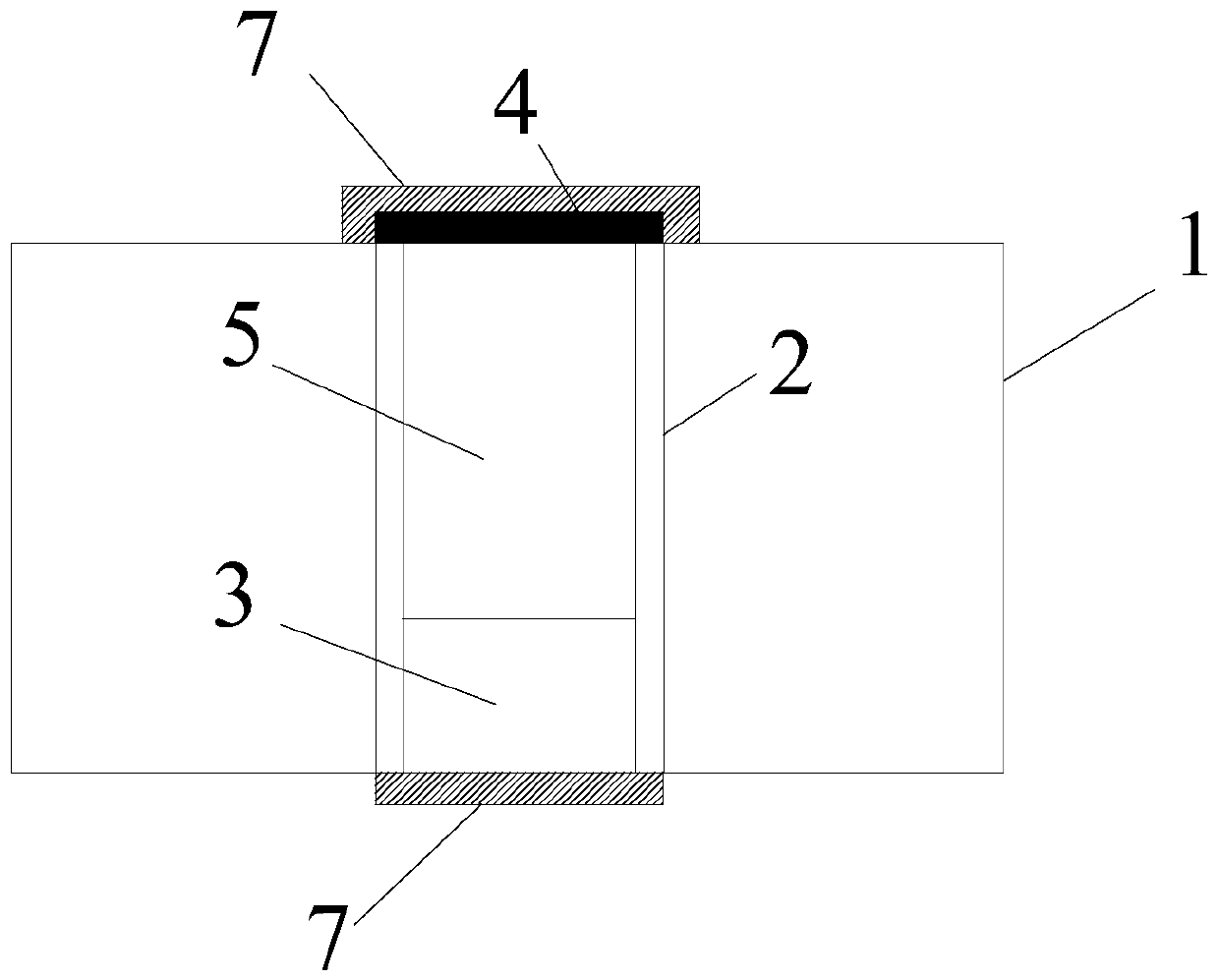

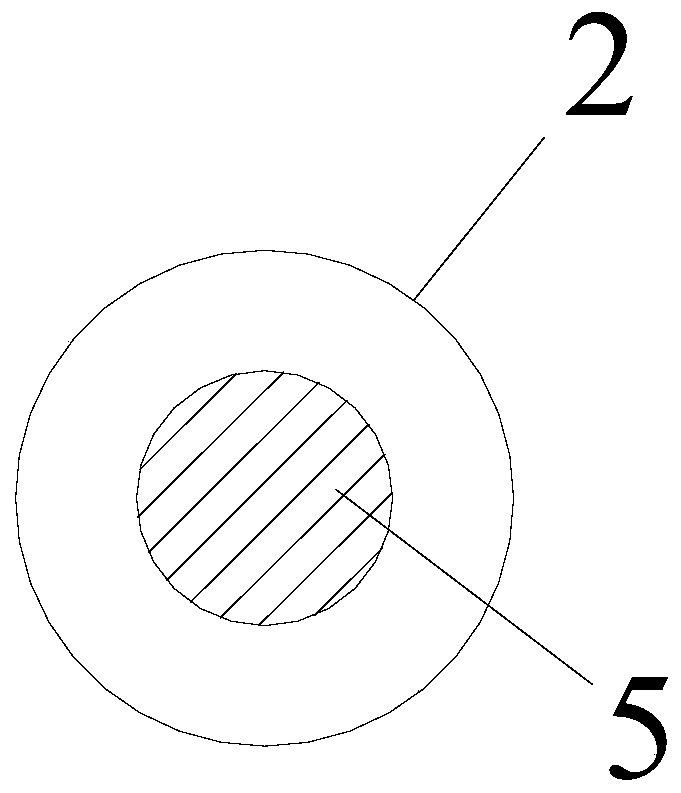

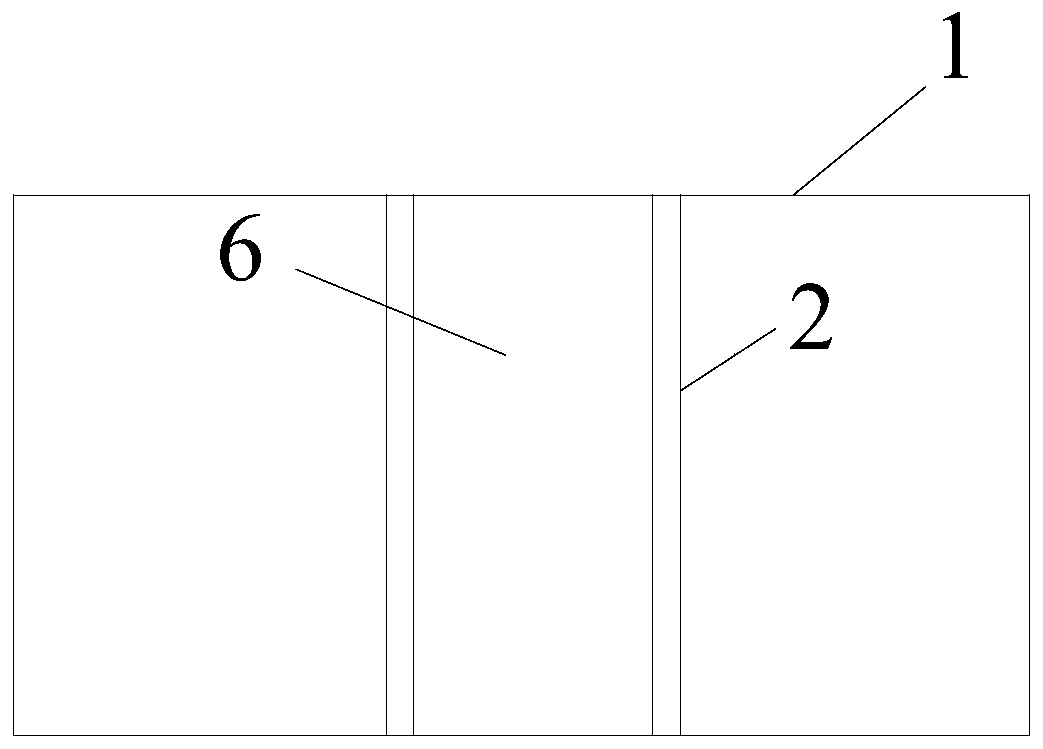

The invention discloses a display device, a preparation method thereof, and a display device. The display device includes a carrier, on which nanotubes are arranged, and inside the nanotubes are provided accommodation chambers with openings at both ends. A first electrode and a luminescent layer are provided, the first electrode encapsulates one end opening of the accommodating cavity, and the end opening of the accommodating cavity away from the first electrode is encapsulated by a second electrode, and the luminescent layer is located in the second electrode. Between the first electrode and the second electrode; the display device realizes self-encapsulation, which saves the usage of packaging materials to the greatest extent and reduces the cost.

Description

technical field The invention relates to the display field, in particular to a display device, a manufacturing method thereof, and a display device. Background technique Organic light-emitting diodes, that is, OLEDs, have excellent characteristics such as ultra-thin, low power consumption, fast response speed, self-illumination, high contrast, wide viewing angle, and can be used for flexible panels. The general OLED manufacturing process is to deposit the anode, hole injection layer, light-emitting layer, and cathode in sequence, and a diaphragm of a specific film quality must be specially set between individual pixels to separate them, and then the OLED is packaged, which is a complicated process; and the packaging material is coated. During the covering process, the film forming area is large and the utilization rate is low. Contents of the invention In order to solve the above technical problems, the present invention provides a display device, a manufacturing method ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01L51/52H01L51/56B82Y30/00

CPCB82Y30/00H10K71/00H10K59/873H10K50/182H10K2102/3023H10K50/84

Inventor 董晓楠谌伟吴旭黄中浩赵永亮

Owner BOE TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com