Flexible disturbance spike tooth mechanism of high-moisture-content corn threshing cylinder

A technology for corn threshing and high moisture content, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problem of poor threshing effect of high moisture content corn, high threshing loss rate, difficult maintenance and replacement of nail teeth, etc. problem, achieve the effect of reducing the probability of grain breakage, avoiding weak connection and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below through specific implementation manners in conjunction with the accompanying drawings.

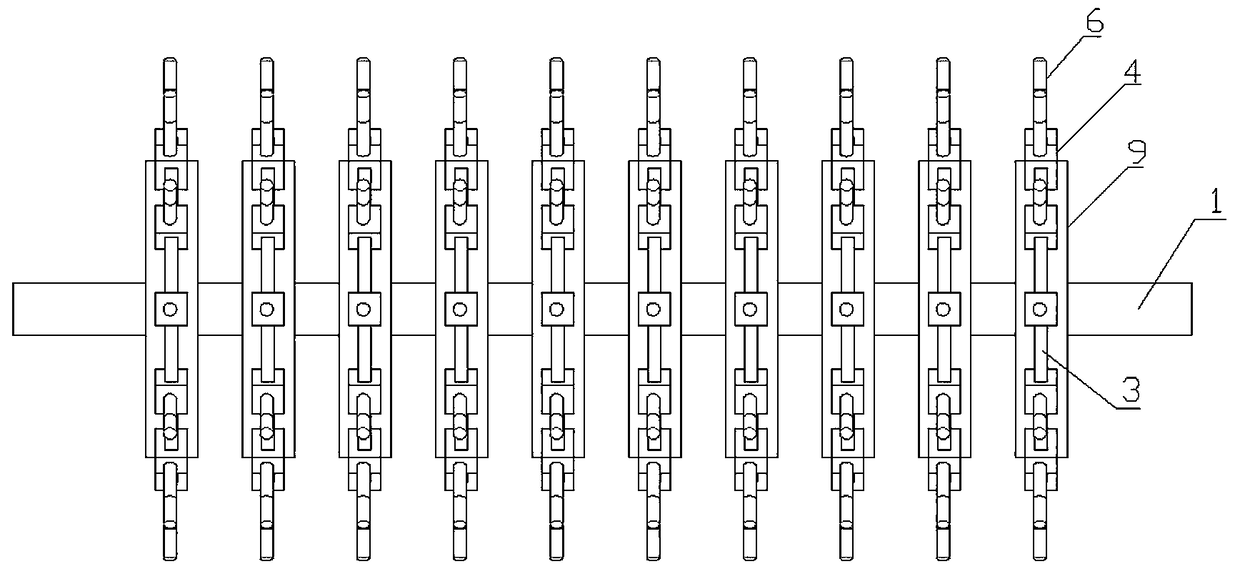

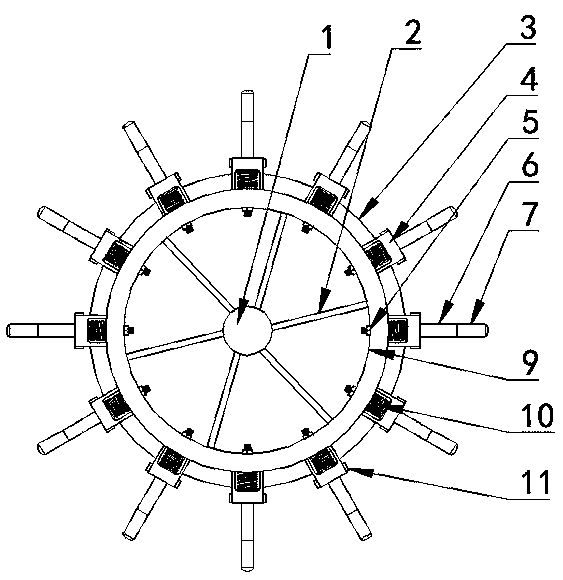

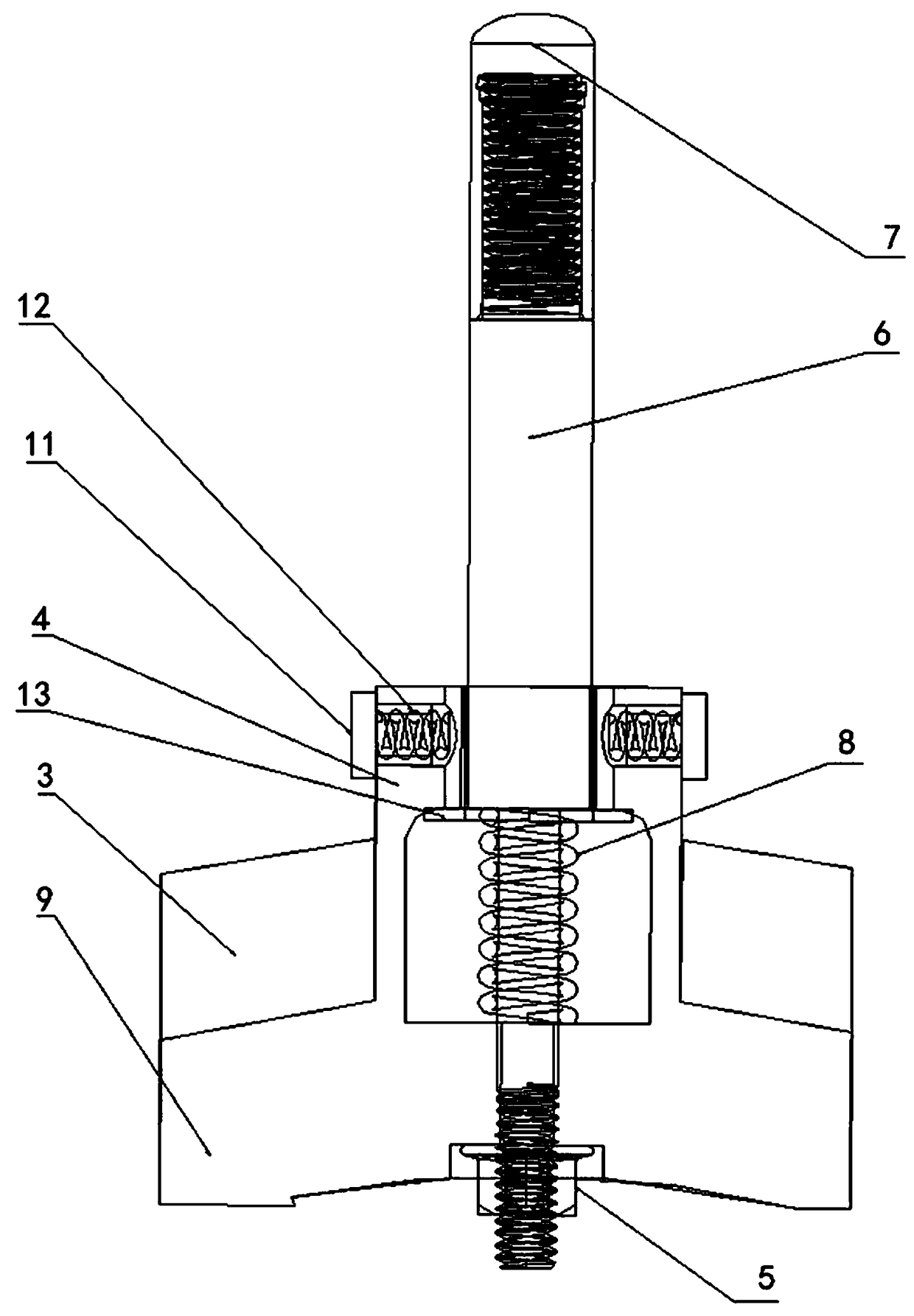

[0025] As shown in the figure, the high moisture content corn threshing drum flexible disturbance nail tooth mechanism of the present invention includes a drum main body composed of a drum shaft 1 and a drum shell 9 through a support plate 2, and the nail teeth 6 are installed on the drum main body; the described The drum shell 9 is a ring structure, the drum shaft 1 passes through the center of the drum shell 9, and there are multiple drum shells 9 arranged in sequence along the axial direction of the drum shaft 1, and the outer circular surface of the drum shaft 1 is welded 6 A support plate 2, the other end of the support plate 2 is welded on the inner circular wall of the drum shell 9, the center of the drum shell 9 falls on the central axis of the drum shaft 1, and the design between the adjacent dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com