Chemical waste liquid filter device

A technology for filtering equipment and waste liquid, which is applied in the direction of filtration and separation, mobile filter element filters, chemical instruments and methods, etc. It can solve the problems of low work efficiency, large disassembly labor, and inconvenient observation and filtration, so as to improve the efficiency of replacement Efficiency, space saving, fast filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

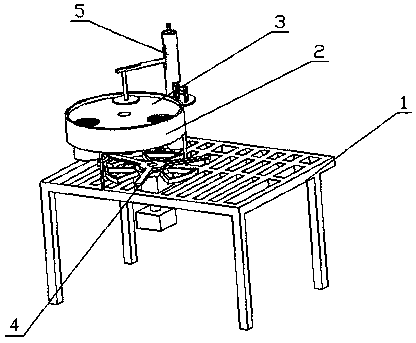

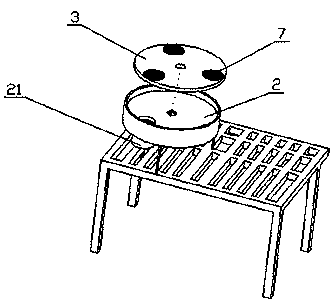

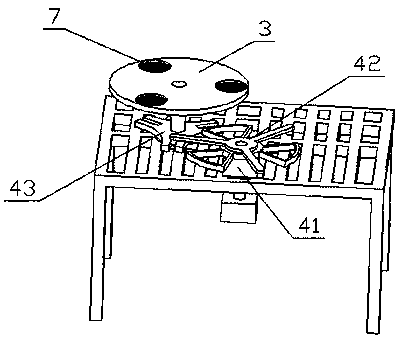

[0023] see Figure 1 to Figure 6 , the present invention is: a chemical waste liquid filtration equipment, comprising a support 1, a support frame 2 arranged on the support 1, a filter disc 3 is arranged on the support frame 2, and a drive mechanism for driving the filter disc 3 to rotate is provided on the support 1 4. The drive mechanism 4 is set on the bottom of the support frame 2, and the pick-and-place mechanism 5 is set on one side of the filter disc 3, and the pick-and-place mechanism 5 is set on the bracket 1.

[0024] The support frame 2 is fixedly connected with the support frame 1 , and a through hole A is arranged on the support frame 2 , and a liquid-taking tube 21 is arranged directly opposite the through-hole A, and the liquid-taking tube 21 is arranged at the bottom of the support frame 2 .

[0025] A filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com