Car seat double-station forming machine and forming method thereof

A car seat and double-station technology, applied to other household appliances, household components, household appliances, etc., can solve the problems of wasting time, low work efficiency, etc., to avoid wasting time, improve production efficiency, and facilitate up and down movement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

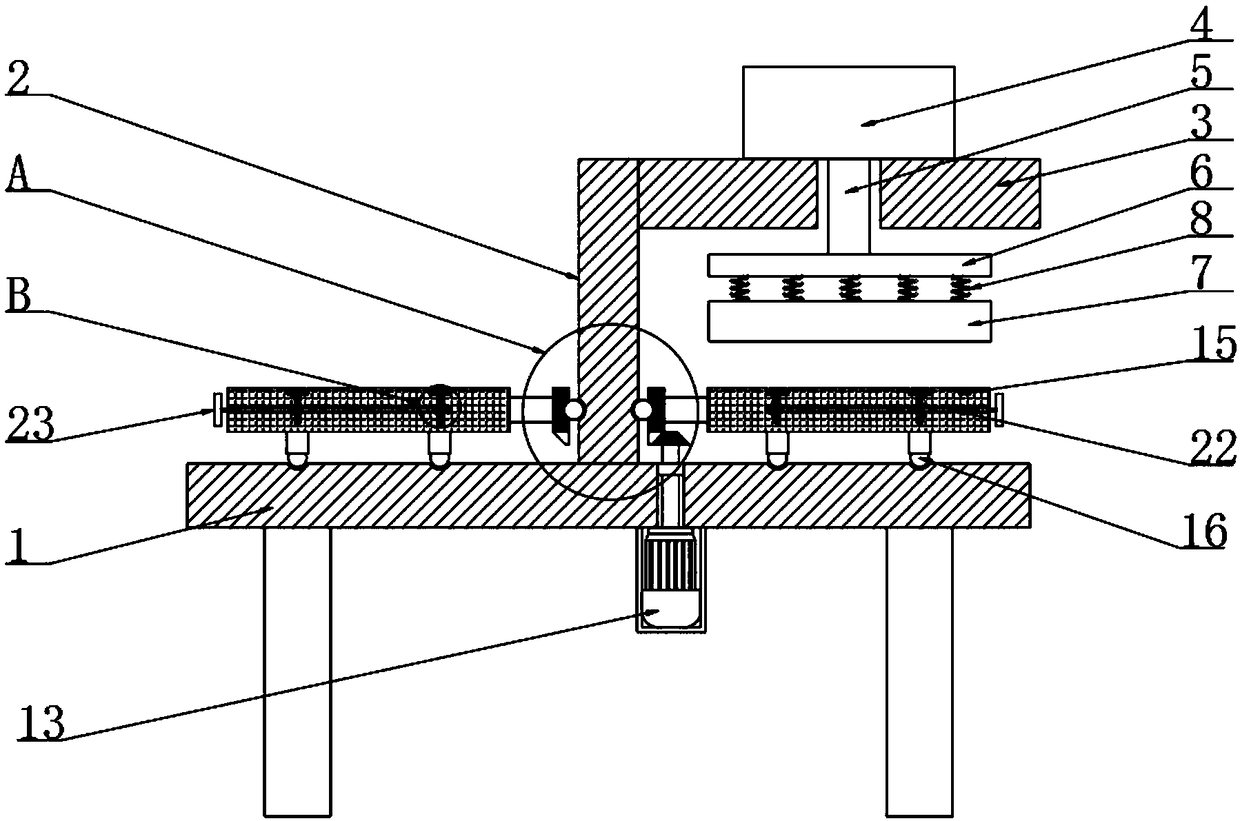

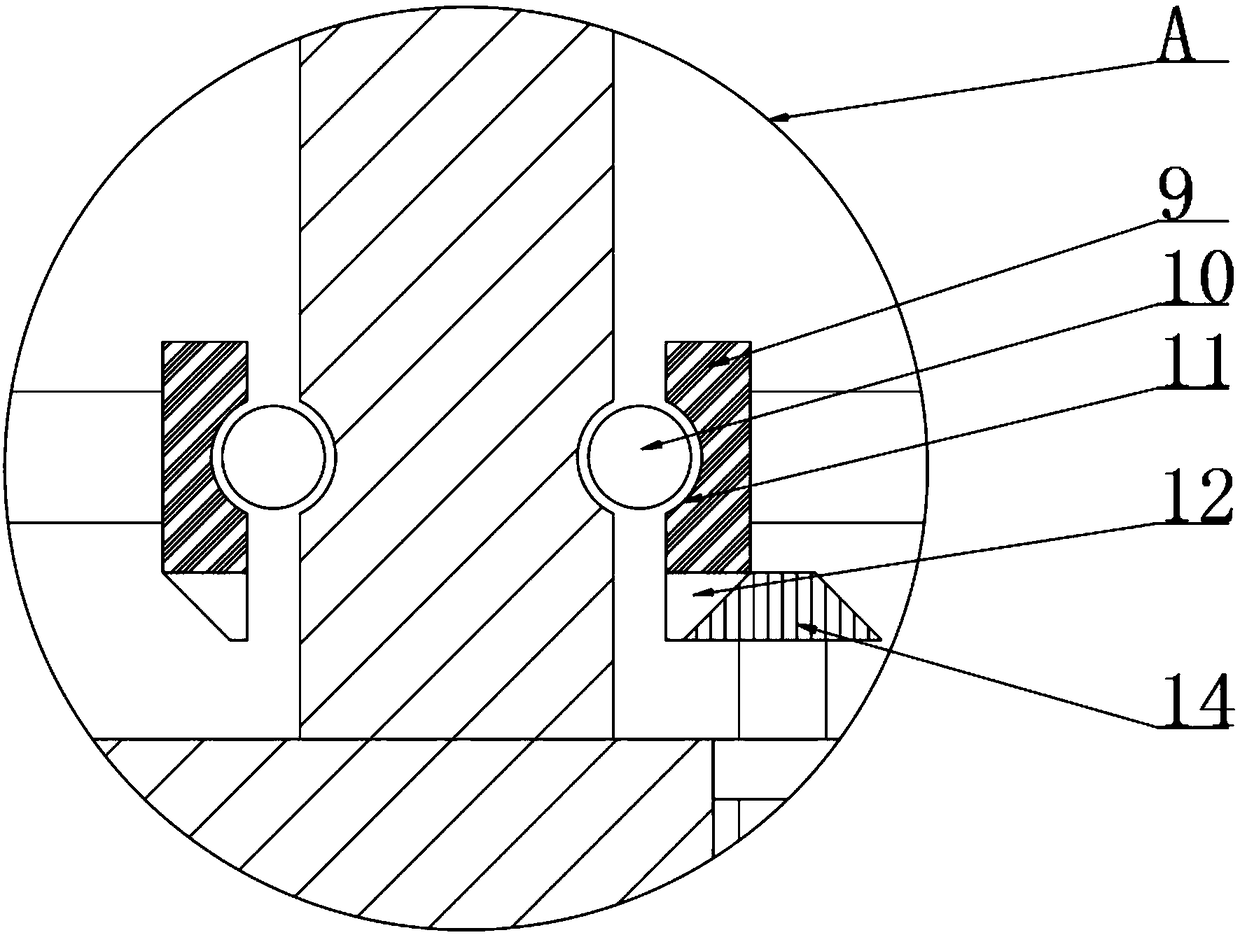

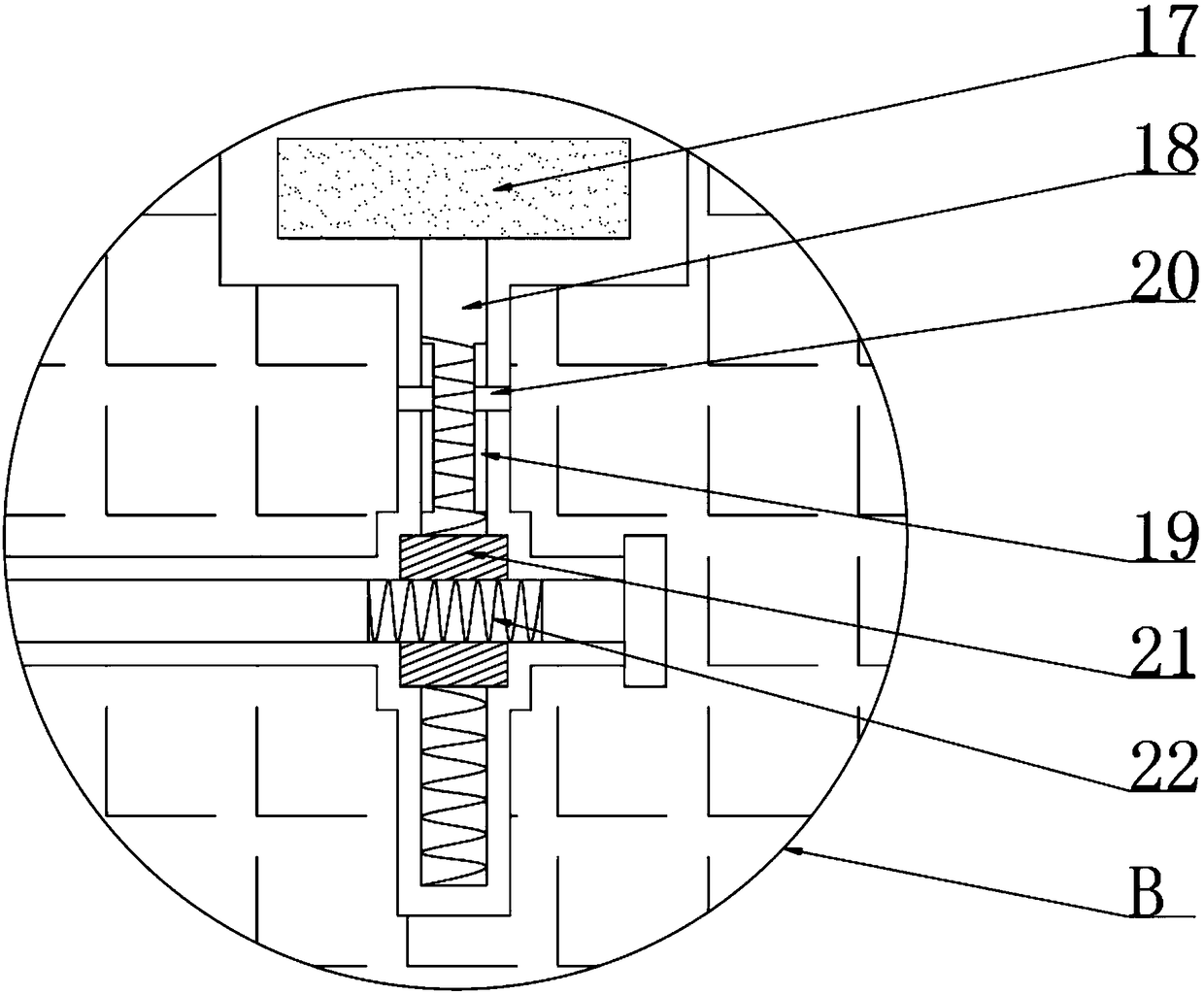

[0025] The present invention provides such Figure 1-3 A double-station molding machine for automobile seats is shown, comprising a workbench 1, a support column 2 is arranged on the top of the workbench 1, a top plate 3 is arranged on one side of the top of the support column 2, and a top plate 3 is arranged on the top There is a hydraulic press 4, the bottom of the hydraulic press 4 is provided with a hydraulic rod 5, and the bottom end of the hydraulic rod 5 is provided with a pressing plate 6, which is conducive to the uniform force applied by the upper mold 7, and the bottom of the pressing plate 6 is provided with an upper Mold 7, a spring 8 is arranged between the pressing plate 6 and the upper mold 7, by being provided with a spring 8, it is beneficial to protect the product, one end of the spring 8 is fixedly connected with the upper mold 7, and the other end of the spring 8 is connected with the pressing plate 6 Fixedly connected, the outer side of the support column...

Embodiment 2

[0035] The forming method of the automobile seat double-station forming machine described in embodiment 1 comprises the following steps:

[0036] Step 1. Both sides of the collar 9 are provided with lower molds 15, and the motor 13 drives the collar 9 to rotate. First, the sheet metal on the car seat is manually installed in one of the lower molds 15. At the same time, the upper template 7 Another lower template 15 is molded to form a car seat, and the car seat is taken out after molding. During the molding time of this car seat, the sheet metal of the lower mold 15 on the other side has been installed;

[0037]Step 2. Then, the position of the lower mold 15 driven by the motor 13 is exchanged. The upper template 7 and the lower mold 15 with the sheet metal installed in step 1 are molded together to form the car seat. After forming, the car seat is taken out, and then step 1 is repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com