Composite door and window sealing strip

A composite sealing strip technology, which is applied in the direction of sealing devices, can solve the problems of poor heat preservation and sound insulation, poor sealing of sealing strips, deformation of right-angle bends, etc. Effect of seal contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

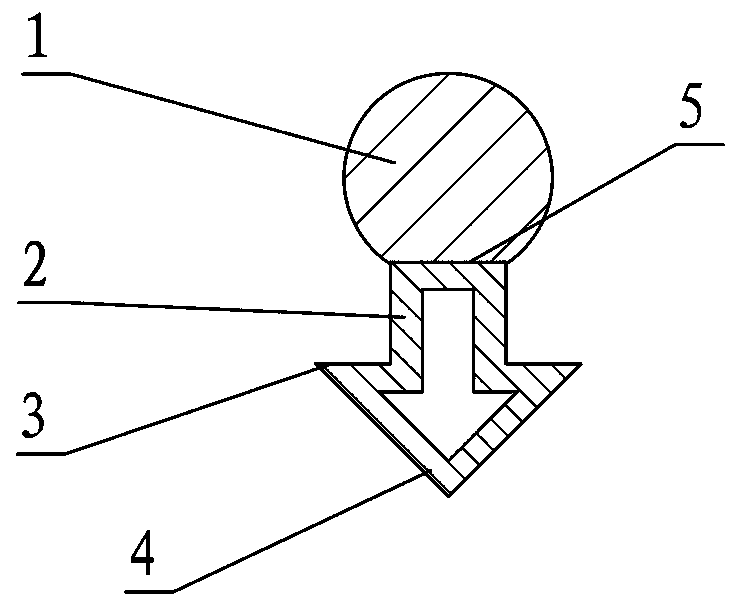

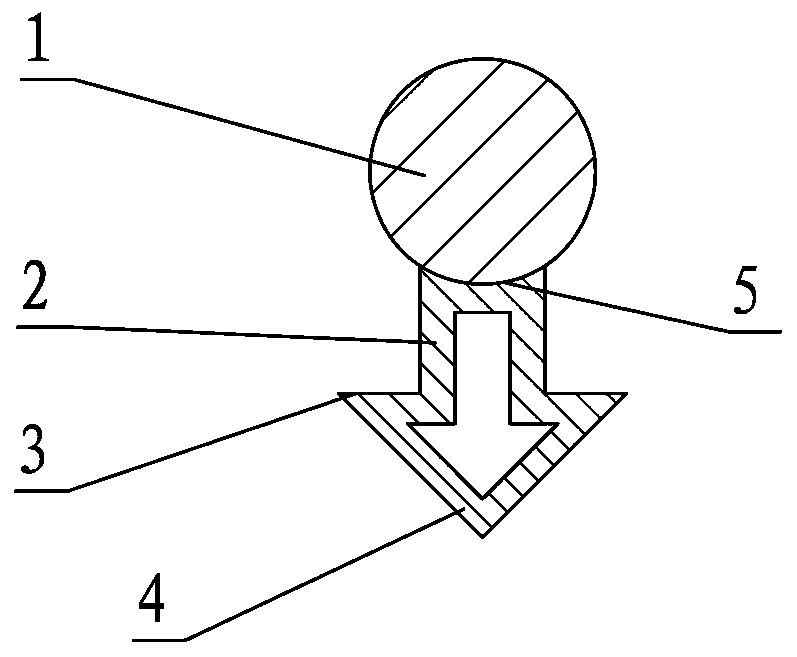

Image

Examples

Embodiment 2

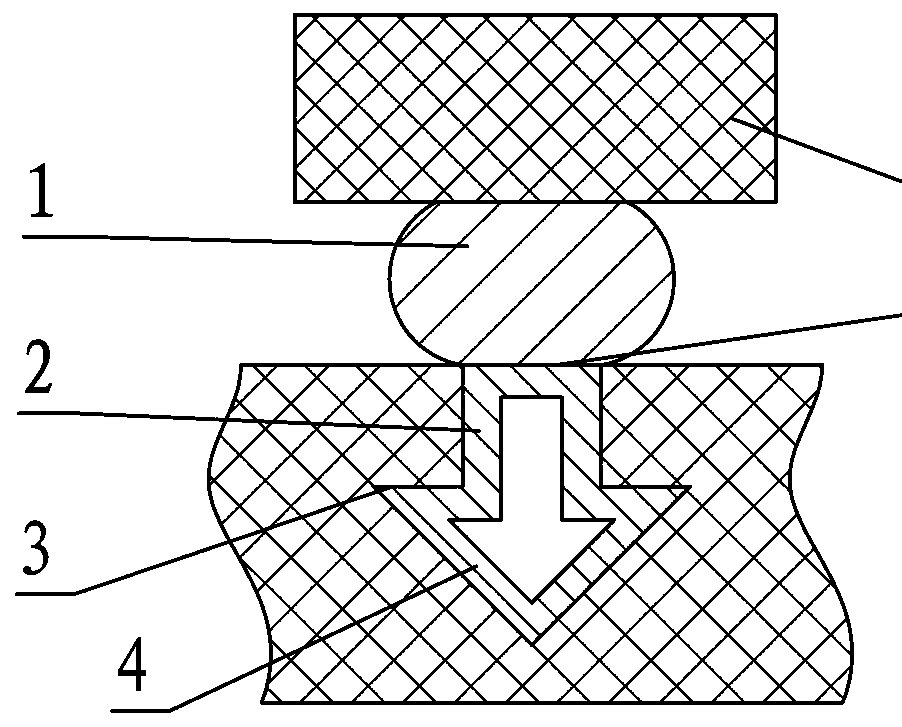

[0028] Embodiment two, such as Figure 4 As shown, the cross-section of the elastic sealing part 1 can also adopt a semi-ellipse or ellipse shape, and the bottom of the cross-section is compositely connected with the connecting part 2 . During use, the area of the sealing contact surface can be increased, so that the outer edge of the elastic sealing part is close to the crimping surface, forming better sealing and heat preservation effects.

Embodiment 3

[0029] Embodiment three, such as Figure 5 As shown, the cross section of the elastic sealing part 1 can adopt a trapezoidal shape with a narrow bottom and a wide top, and a notch 7 can also be provided at the upper end, and the bottom of the cross section is compositely connected with the connecting part 2 . During use, the area of the sealing contact surface can be increased, so that the outer edge of the elastic sealing part is close to the crimping surface, forming better sealing and heat preservation effects.

Embodiment 4

[0030] Embodiment four, such as Figure 6 As shown, the cross-section of the elastic sealing part 1 can adopt a rectangle whose bottom width is equal to the width of the upper end, and a notch 7 can also be provided at the upper end, and the bottom of the cross-section is compositely connected with the connecting part 2 . During use, the area of the sealing contact surface can be increased, so that the outer edge of the elastic sealing part is close to the crimping surface, forming better sealing and heat preservation effects.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com