Washing device and method, developing system and method

A cleaning device and development system technology, applied in the development field, can solve the problems that the development device is prone to developing defects, etc., and achieve the effects of reducing the occurrence of development graphic defects, improving product yield, and reducing transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

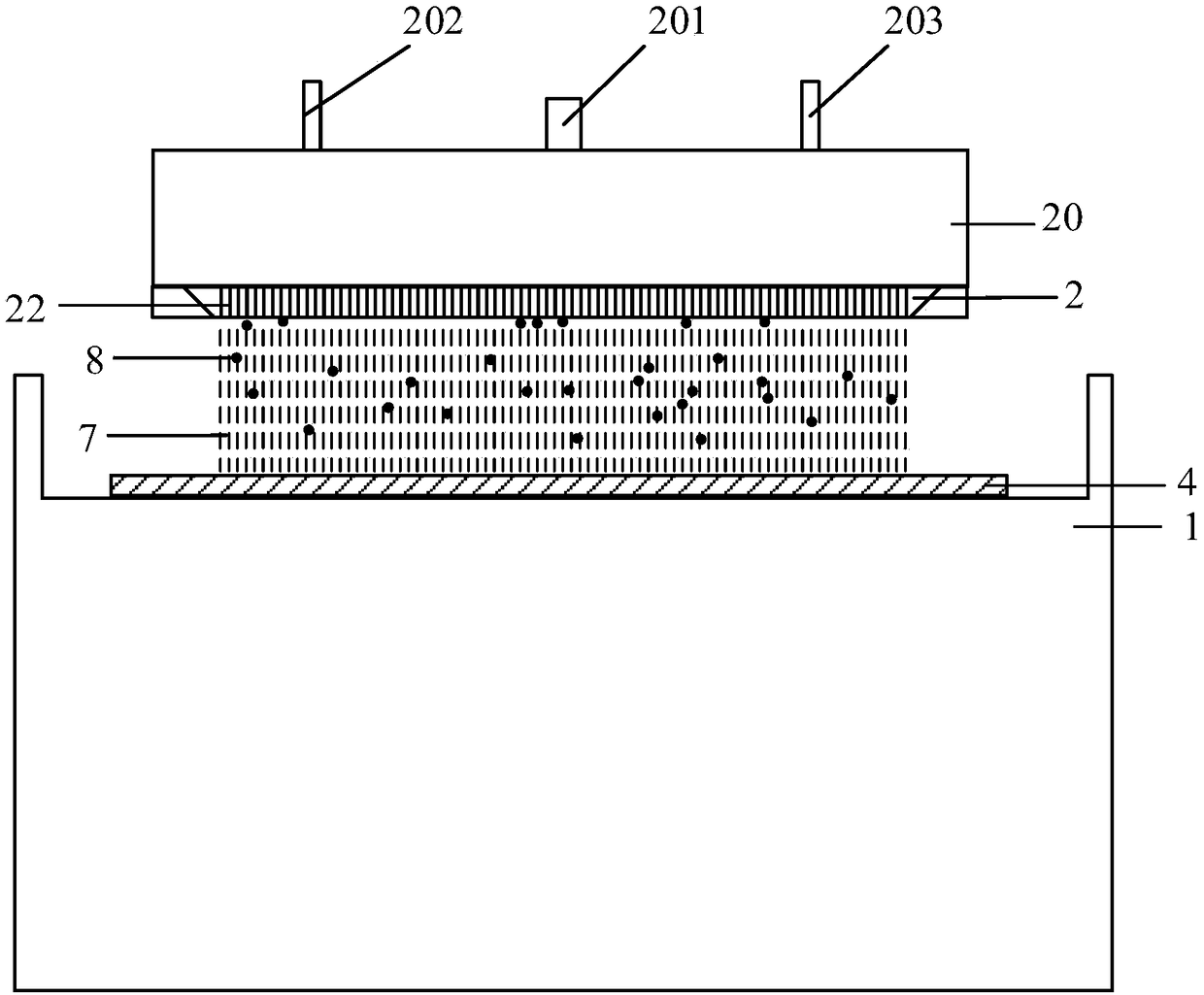

[0029] In the prior art, in the developing device close to the nozzle, in order to reduce the consumption of the developer and improve the effect of CD uniformity, the nozzle (nozzle) with a long nozzle closer to the surface of the wafer (Wafer) is adopted. However, in the development in the process, such as figure 1 As shown, since the nozzle hole 22 is closer to the surface of the wafer 4, surface tension is easily generated when the developer is sprayed, and the fine particle residue 8 (particle) generated after the reaction between the developer and the photoresist is attached to the surface through the counterflow of the surface tension. On the nozzle 2, the nozzle 2 is polluted, and the polluted nozzle 2 will bring the particle residue to the wafer when the developer is sprayed on the subsequent wafer, so that the wafer is contaminated and causes the pattern defect of the development. It affects the development effect of subsequent wafers and greatly reduces the product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com