Battery cell film-coating machine

A technology of coating machine and battery core, which is applied in the direction of assembling battery machines, circuits, electrical components, etc. It can solve the problems affecting the performance and safety of battery cores, affecting the assembly process of shells, and low production efficiency, so as to improve production efficiency , Shorten coating time, improve safety and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make those skilled in the art more clearly understand the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

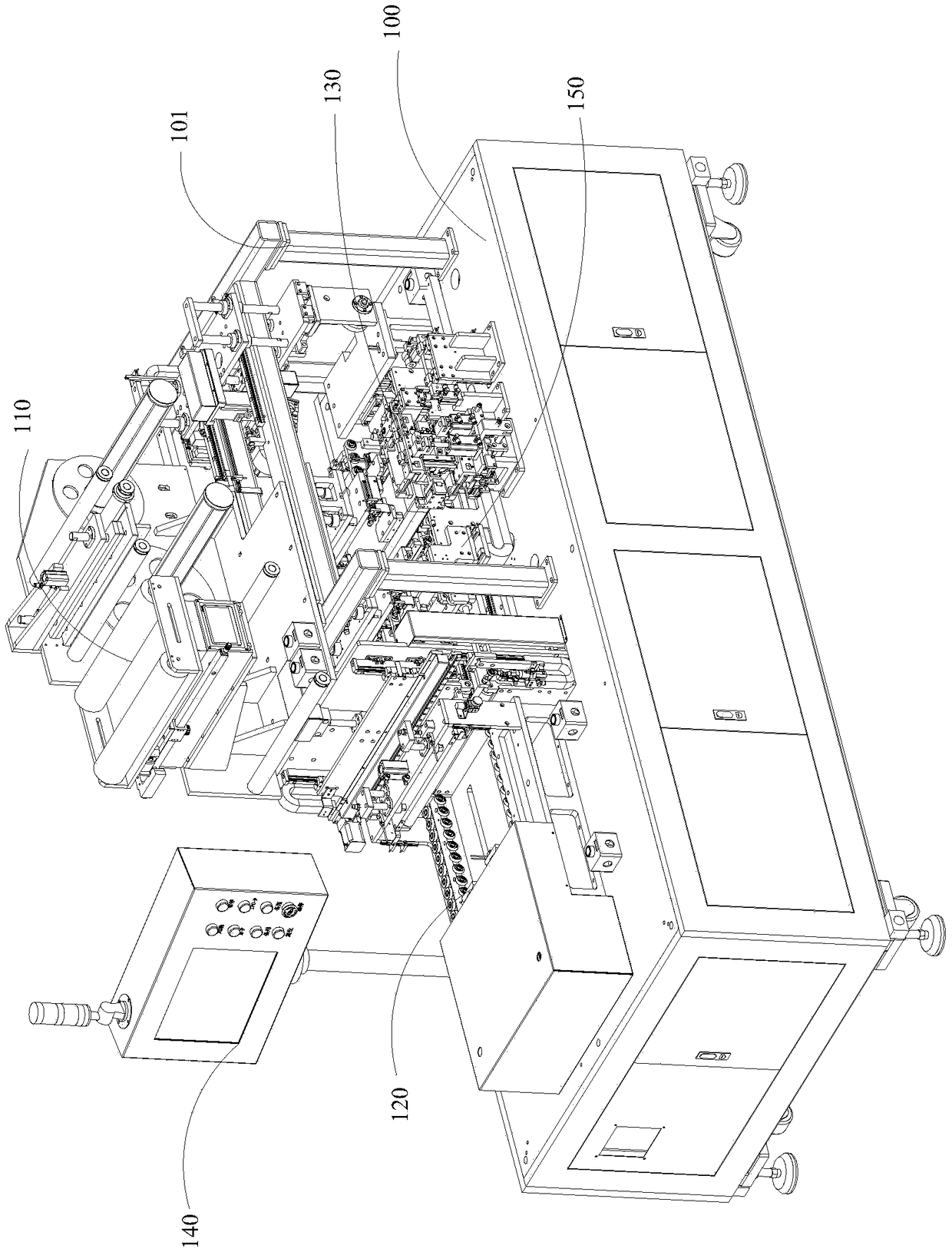

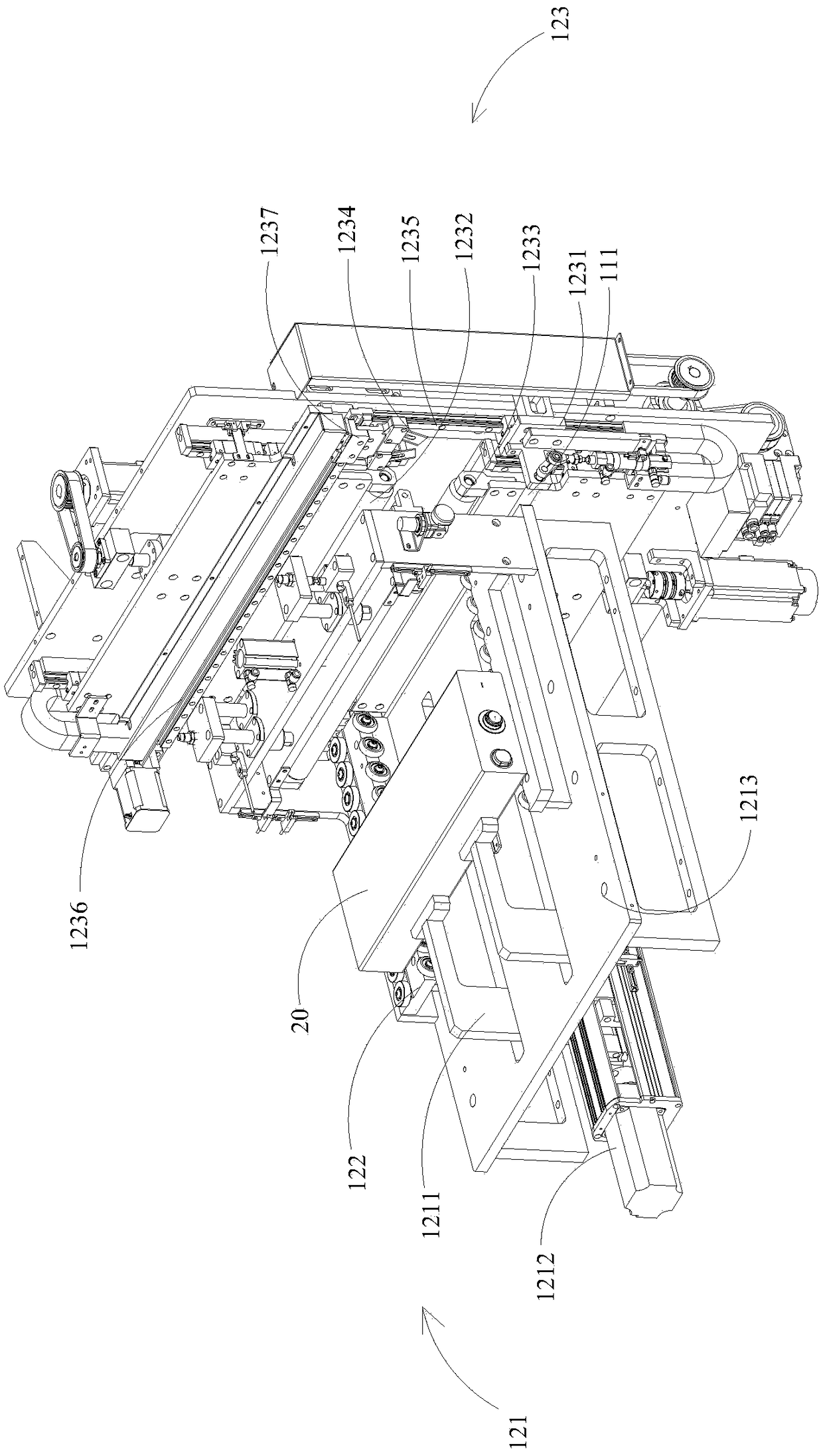

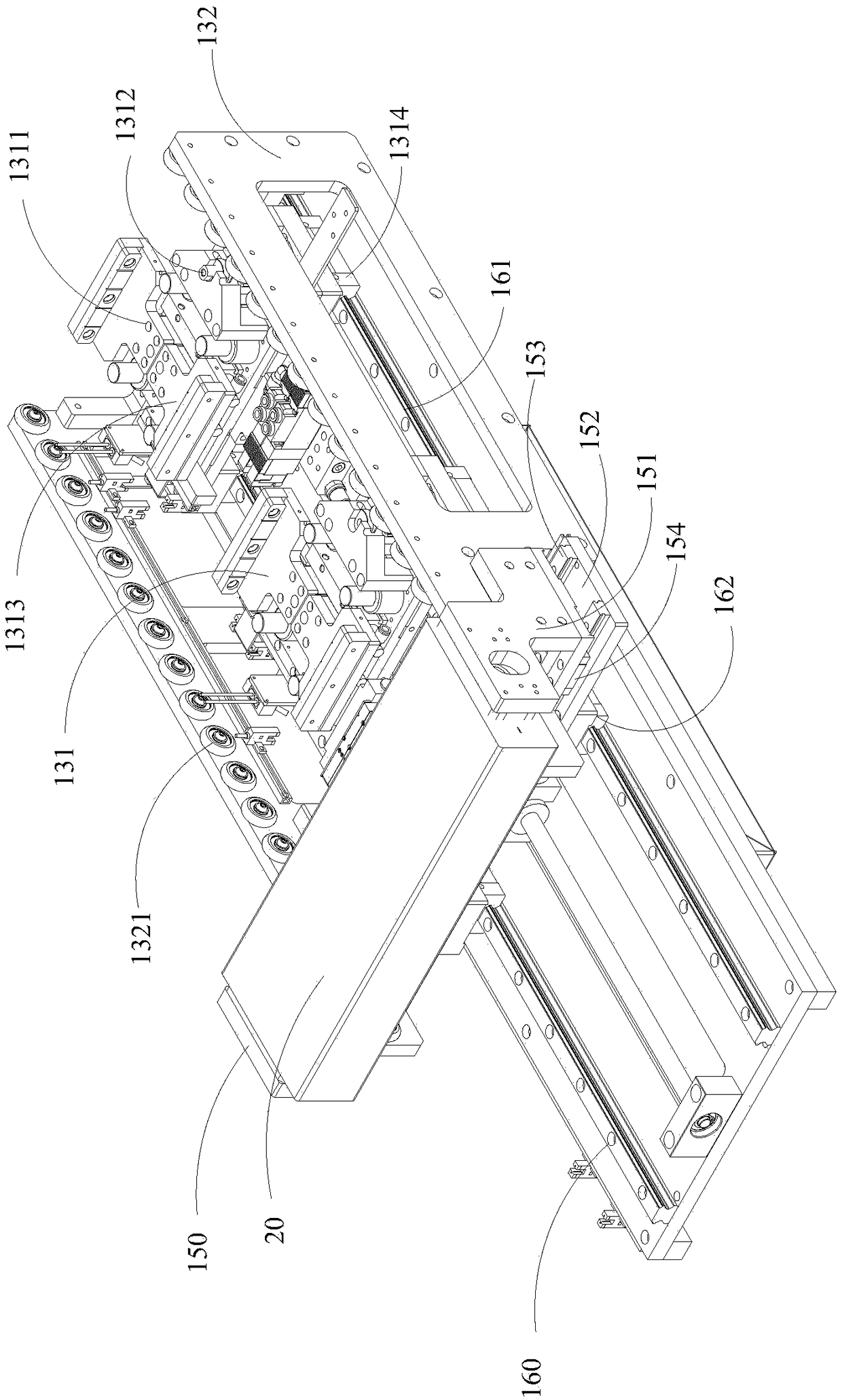

[0023] refer to Figure 1 to Figure 3 , in one embodiment of the present invention, the battery coating machine includes a frame 100, a film release mechanism 110, a ring coating mechanism 120, a pole column coating mechanism 130 and a control mechanism 140 . The film releasing mechanism 110 is erected on the frame 100 through the supporting frame 101 , an insulating film is placed in the film releasing mechanism 110 , and one end of the insulating film is pulled down onto the frame 100 by a film pulling shaft 111 . The control mechanism 140 is arranged on one side of the frame 100, and is respectively connected with the annular coating mechanism 120, the pole column coating mechanism 130 and the film releasing mec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap