Strawberry picking machine

A technology for picking machines and strawberries, which is applied in the directions of picking machines, harvesters, agricultural machinery and implements, can solve the problems of damage to the integrity of strawberry fruits, difficulty in automatic harvesting, and high labor intensity, and achieves strong portability and compact structure. , the effect of raising the level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

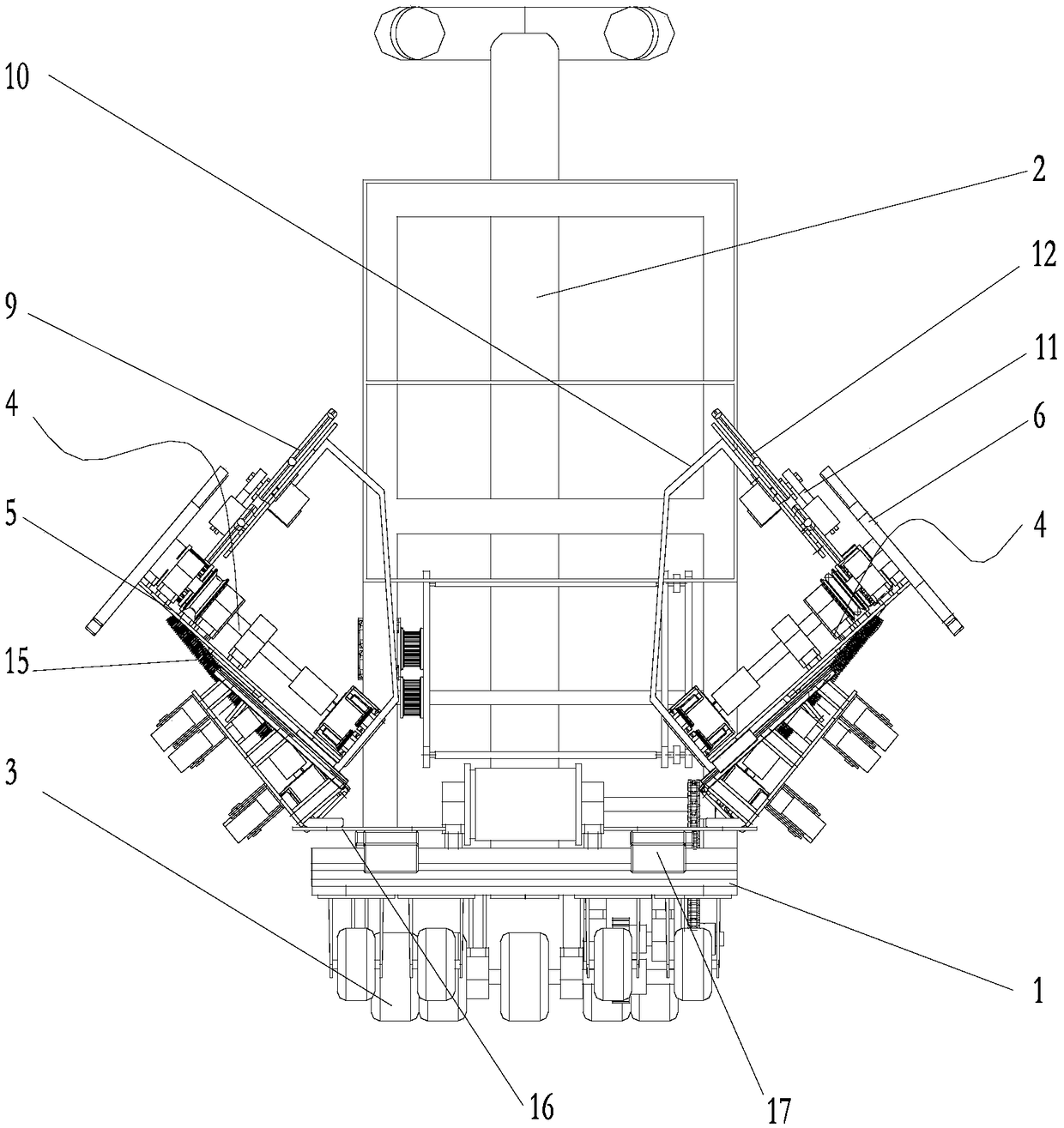

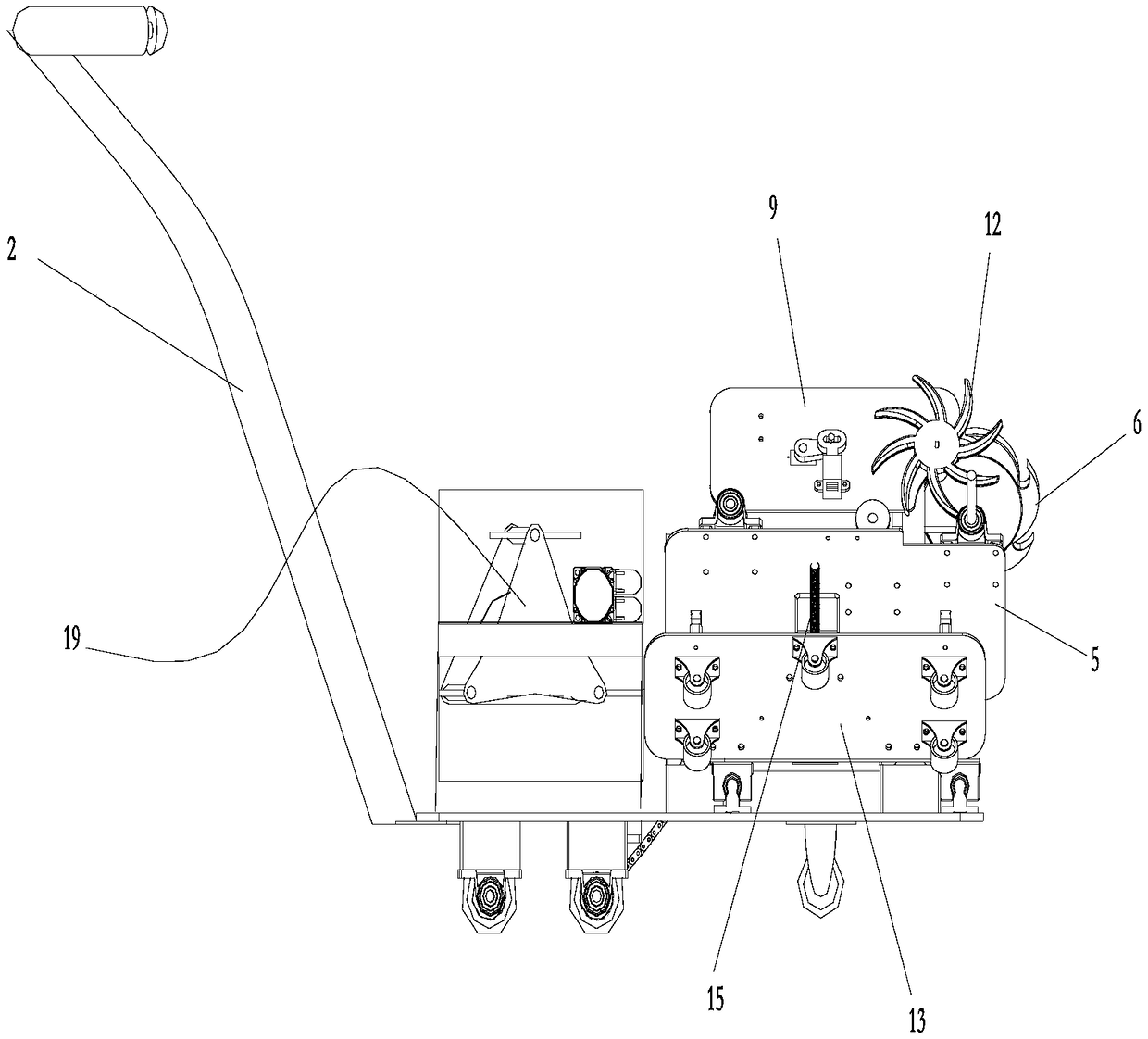

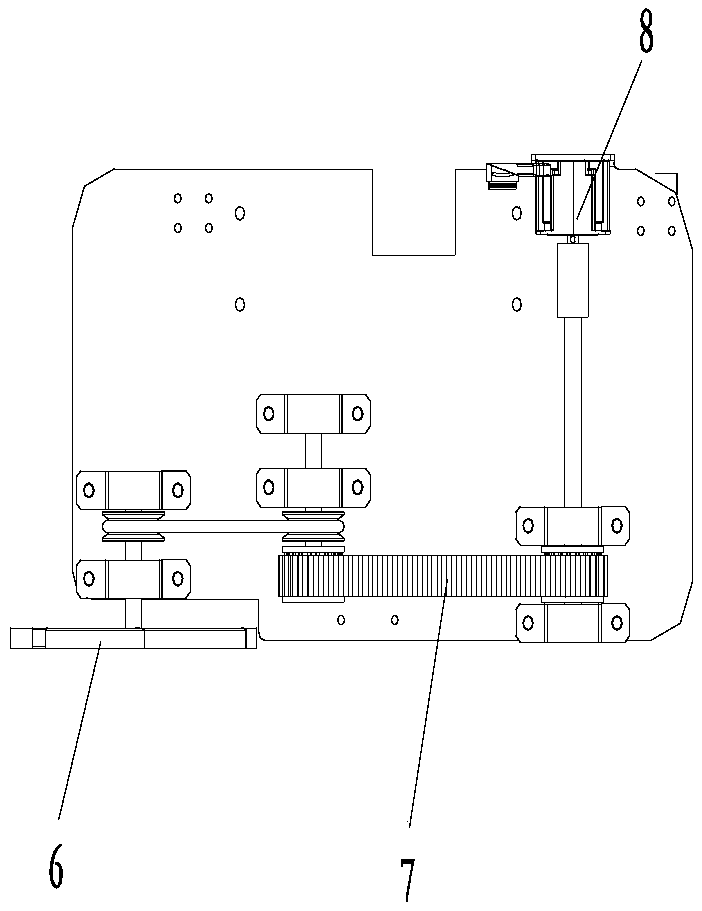

[0026] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a side view of the present invention, image 3 It is a schematic diagram of the structure of the inclined plate of the present invention. As shown in the figure, the strawberry picking machine in this embodiment includes a base plate 1, a hand push rod 2 arranged at the longitudinal rear end of the base plate, and a walking roller 3 arranged at the bottom of the base plate And the picking mechanisms 4 on both sides of the base plate are respectively arranged; the base plate is rectangular, the length direction is vertical, and the width direction is horizontal;

[0027] The picking mechanism includes an upper slant plate 5 fixed on the base plate, a berry picking assembly installed on the upper slant plate, and a berry picking assembly for deciding whether to pick berries according to the color of the strawberries; picking berries means lifting the strawberries from the slope to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com