Low-sugar and high-flagrance maple extract and preparation method and application in heating non-burning cigarette thereof

A heat-not-burn, high-flavored maple technology, which is applied in the fields of tobacco preparation, application, and smoker's products, can solve the problems of low content of volatile aroma components and the inability to meet the requirements of flavoring and adding materials to heat-not-burn cigarettes, and achieve high aroma intensity, Improve the richness of cigarette aroma and prevent oxidative deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of low-sugar high-fragrant maple extract, which specifically comprises the following steps:

[0026] 1) In a 500mL autoclave reactor, add 150g of maple sap, cover and seal, open the air inlet and air outlet, fill nitrogen through the air inlet, and discharge the air inside the reactor through the air outlet. Then close the air outlet, fill in nitrogen again, adjust the temperature of the autoclave reactor to 200°C, and the pressure to 1.0 MPa, and react for 4 hours to obtain the maple sap of high temperature and high pressure reaction; cool to room temperature, and set aside;

[0027] 2) Transfer the maple sap from the high temperature and high pressure reaction obtained in step 1) to a 500mL reactor, fill it with nitrogen protection, put it into a microwave reactor, control the microwave power to 600 W, and microwave for 30 minutes. After the reaction, the maple sap of the microwave reaction was obtained; naturally cooled to room temperature, for s...

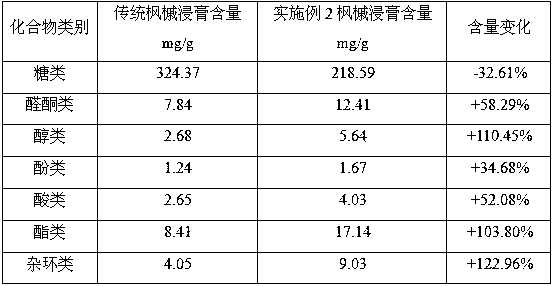

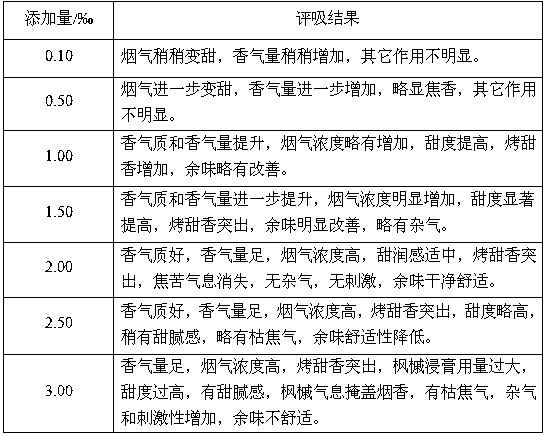

Embodiment 2

[0031] A preparation method of low-sugar high-fragrant maple extract, which specifically comprises the following steps:

[0032] 1) In a 500mL autoclave reactor, add 200g of maple sap, cover and seal, open the air inlet and air outlet, fill nitrogen through the air inlet, and discharge the air inside the reactor through the air outlet. Then close the air outlet, fill in nitrogen again, adjust the temperature of the autoclave reactor to 250 ° C, the pressure to 2.0 MPa, and react for 3 h to obtain the maple sap of high temperature and high pressure reaction; cool to room temperature and set aside;

[0033] 2) Transfer the maple sap from the high temperature and high pressure reaction obtained in step 1) to a 500mL reactor, fill it with nitrogen protection, put it into a microwave reactor, control the microwave power to 800 W, and microwave for 20 minutes. After the reaction, the maple sap of the microwave reaction was obtained; naturally cooled to room temperature, for subseque...

Embodiment 3

[0037] A preparation method of low-sugar high-fragrant maple extract, which specifically comprises the following steps:

[0038] 1) In a 500mL autoclave reactor, add 250g of maple sap, cover and seal, open the air inlet and air outlet, fill nitrogen through the air inlet, and discharge the air inside the reactor through the air outlet. Then close the air outlet, fill in nitrogen again, adjust the temperature of the autoclave reactor to 300 °C, and the pressure to 2.5 MPa, and react for 2 h to obtain the maple sap of high temperature and high pressure reaction; cool to room temperature and set aside;

[0039] 2) Transfer the maple sap from the high temperature and high pressure reaction obtained in step 1) to a 500mL reactor, fill it with nitrogen protection, put it into a microwave reactor, control the microwave power to 1000 W, and microwave for 15 minutes. After the reaction, the maple sap of the microwave reaction was obtained; naturally cooled to room temperature, for subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com