Supporting structure for manufacturing dental department additional material

A technology of additive manufacturing and support structure, applied in the field of dental prosthesis, can solve the problem of high powder consumption, and achieve the effect of saving powder consumption, ensuring support strength, and good support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

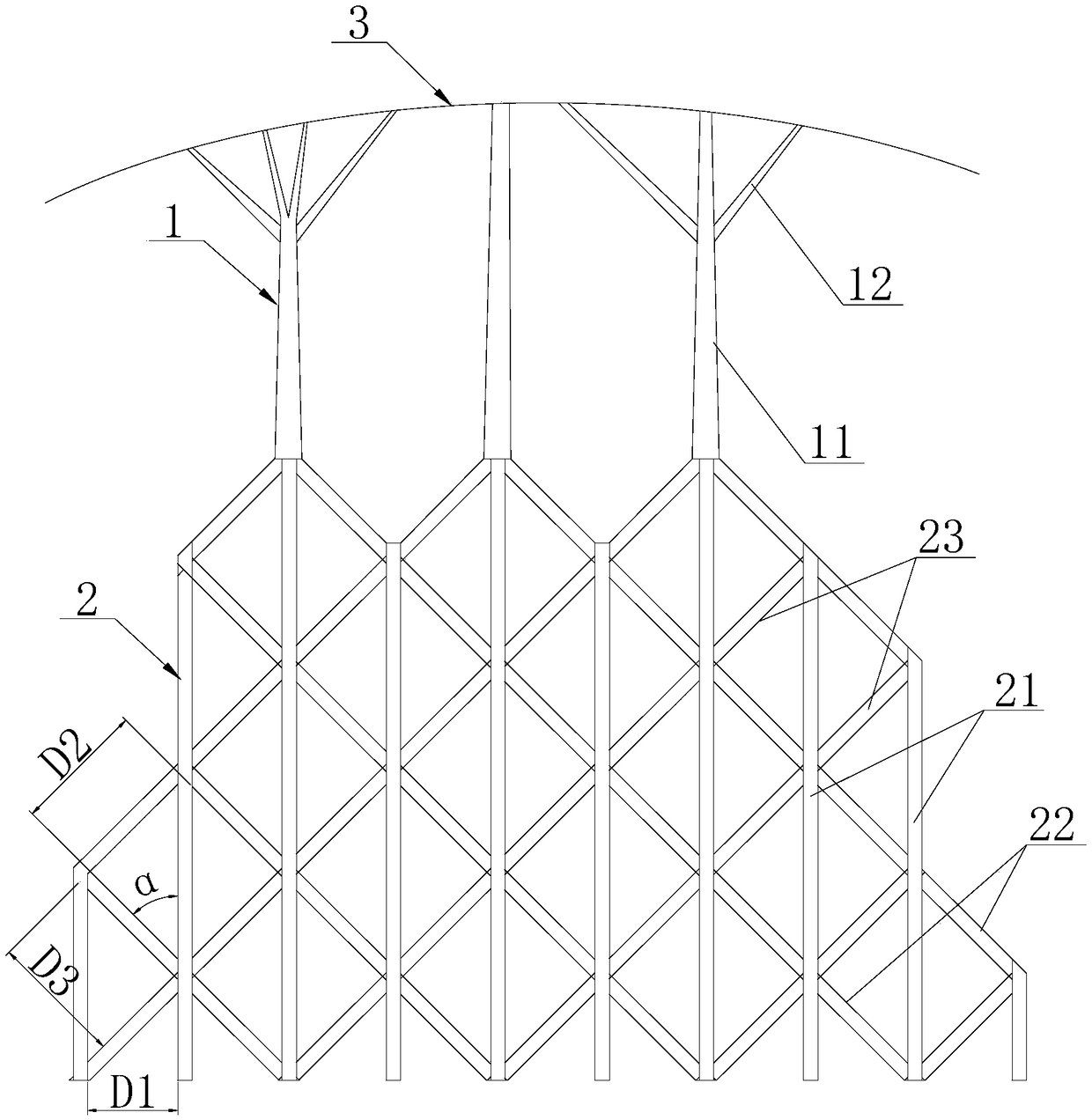

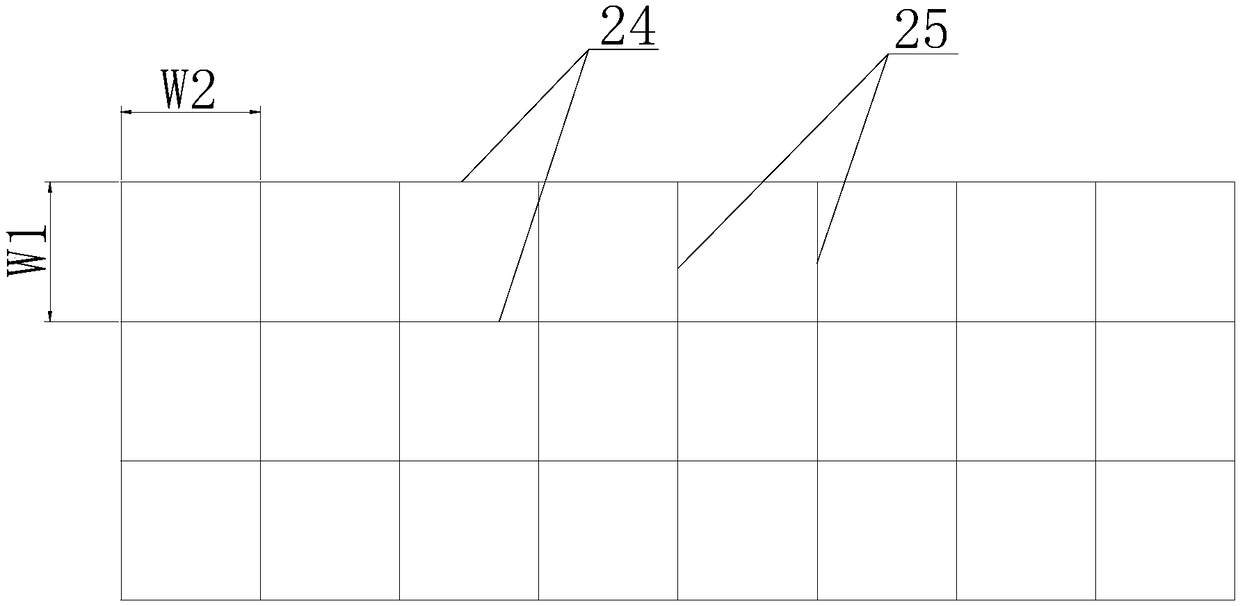

[0025] As shown in the figure, the support structure for dental additive manufacturing disclosed by the present invention includes a tree-shaped support part 1 at the upper part and a sheet mesh support part 2 at the lower part; The trunk 11 connected by the grid support part 2 and the branches 12 located on the trunk 11; the sheet grid support part 2 is a grid-like structure composed of sheets.

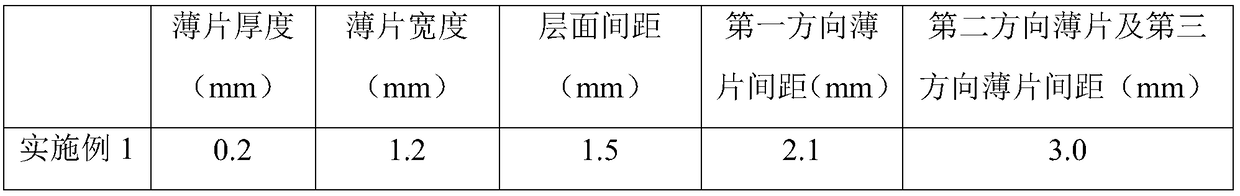

[0026] In this support structure, the branches 12 of the tree-shaped support part 1 on the upper part are in contact with the molded part to support the hanging surface 3 of the molded part. The trunk 11 mainly plays the role of supporting the branches 12. It is a grid-like structure composed of flakes, which greatly saves the amount of powder used in additive manufacturing while ensuring the support strength. Under the condition of comprehensively considering its performanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com