Filter cylinder and dust collector

The technology of a dust collector and a filter cartridge is applied to the filter cartridge. , Separation device, dust collector field, can solve the problems of large space required, increase the overall height of the dust collector, affect the dust collection effect, etc., to achieve the effect of guaranteed service life, better vibration effect, and lower technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

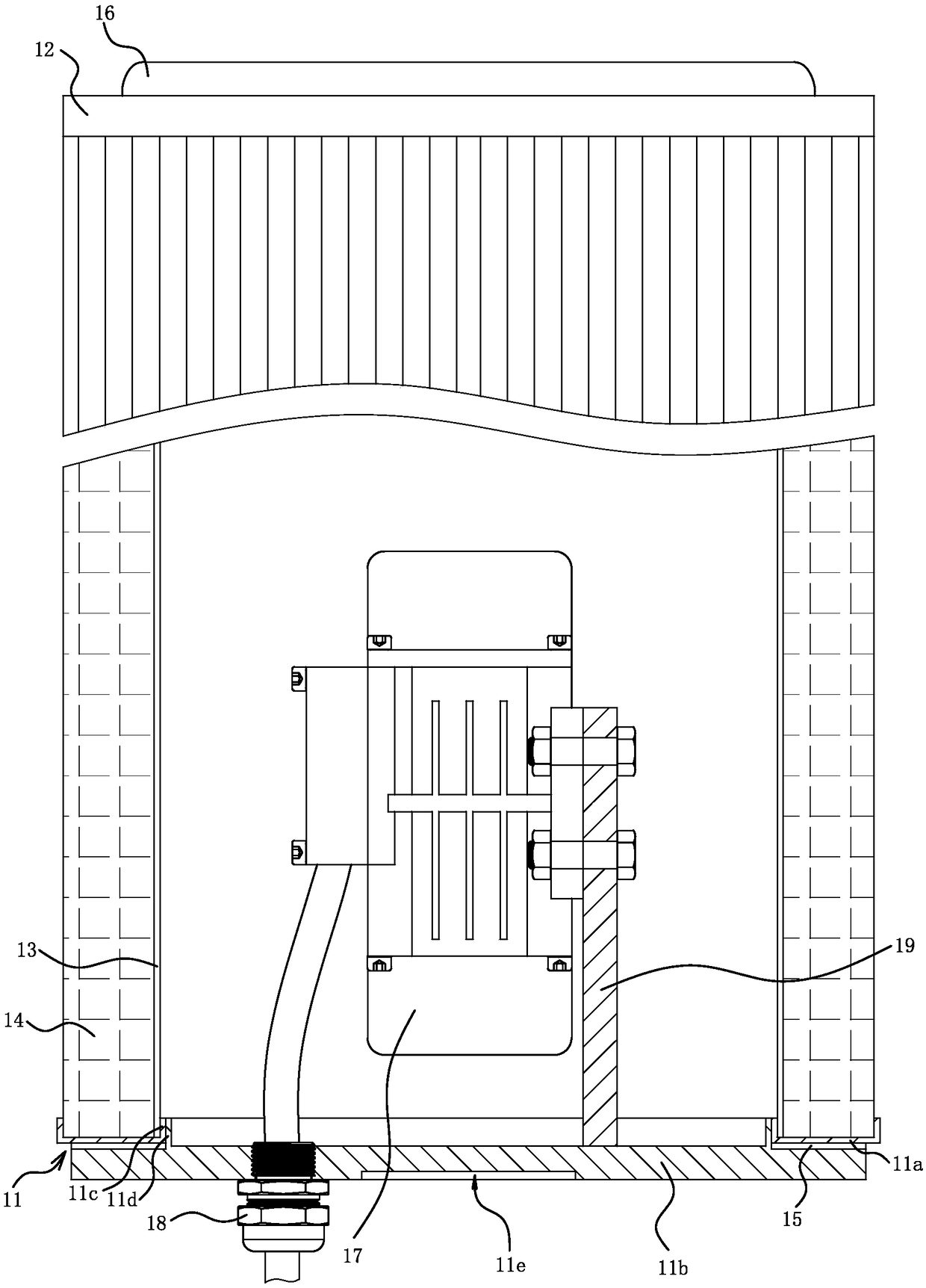

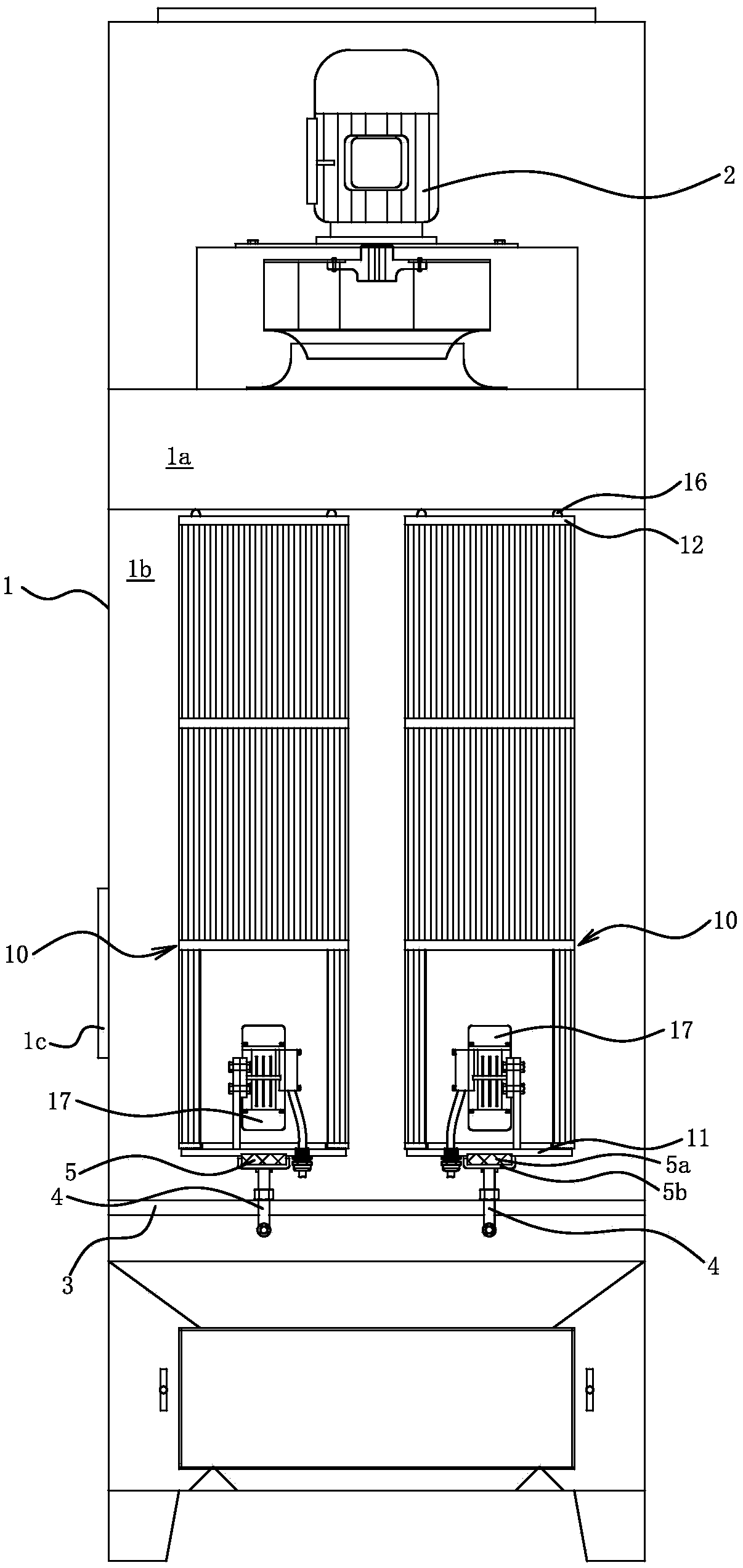

[0024] Such as figure 1 As shown, the filter cartridge 10 includes a bottom plate 11 , a top plate 12 , a liner 13 and a filter cartridge body 14 . The bottom plate 11 includes an annular outer ring 11a and a center plate 11b that can cover the center hole of the outer ring 11a. A sealing sheet 15 is embedded between the outer ring 11a and the center plate 11b. This structure effectively ensures that the outer ring 11a and the center The tightness between the plates 11b prevents dusty air from directly entering the filter cartridge 10 . The inner side of the outer ring 11a has a flange 11c, and the center plate 11b has a positioning bead 11d, the positioning bead 11d is embedded in the center hole of the outer ring 11a, and the flange 11c of the outer ring 11a relies on the positioning bead 11d, thereby limiting The center plate 11b slides to improve the installation stability of the center plate 11b.

[0025] The filter cartridge body 14 is cylindrical, and the top plate 12...

Embodiment 2

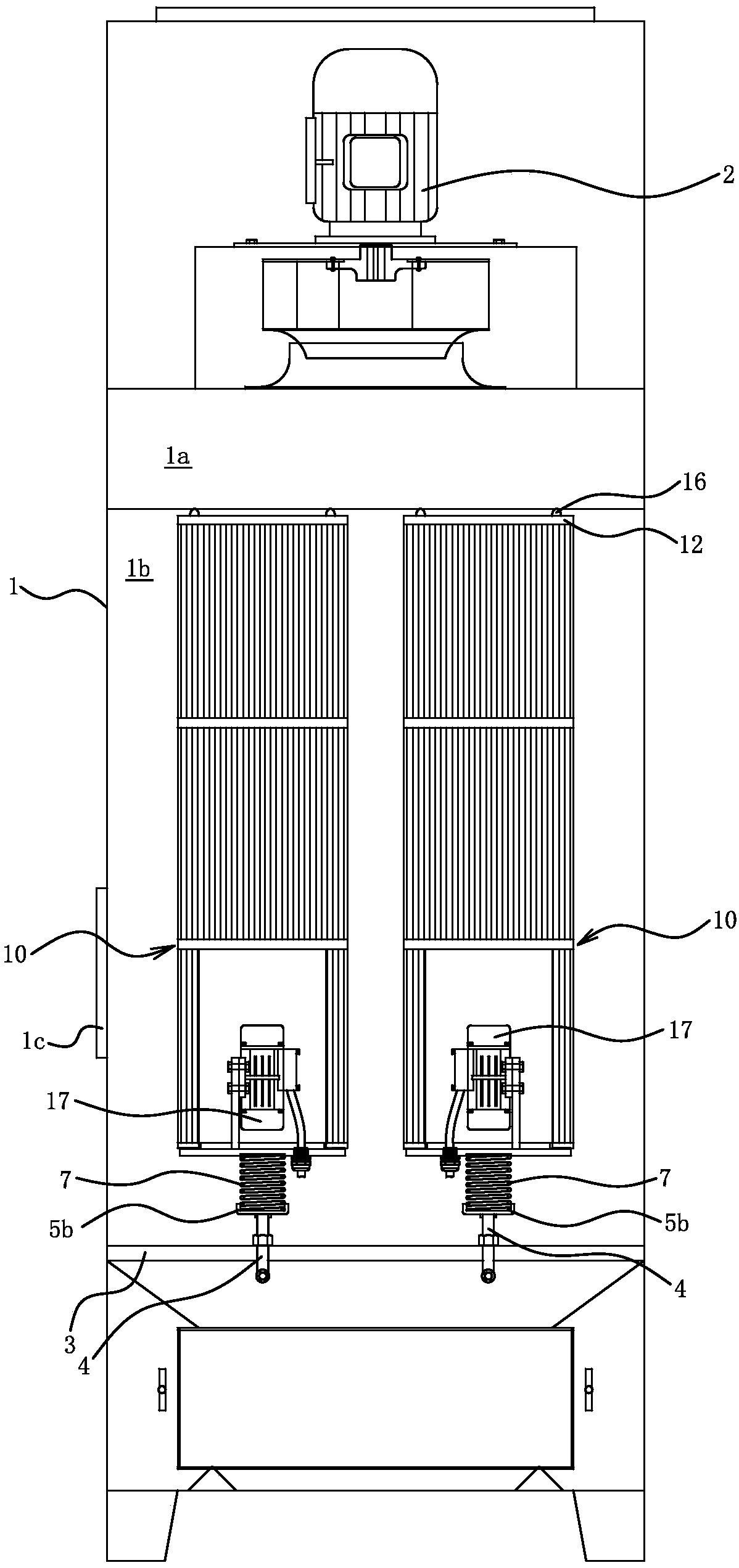

[0034] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be redundantly described, and only the differences will be described, and the differences are as follows: image 3 As shown, the shock absorber 5 can be replaced by the following scheme, the shock absorber 5 includes a spring 7 and a supporting plate 5b. The upper end of the spring 7 abuts against the bottom surface of the central plate 11b, the lower end of the spring 7 is embedded in the supporting plate 5b, and the locking bolt 4 is embedded in the supporting plate 5b; the spring 7 is in a compressed state.

Embodiment 3

[0036] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be redundantly described, and only the differences will be described, and the differences are as follows: Figure 4 As shown, the outer ring 11a and the central plate 11b are connected through a detachable fixed structure; specifically, the outer ring 11a and the central plate 11b are fixedly connected through the feet 11g and fastening bolts 11f; according to the actual situation, the outer ring Screw connection can also be adopted between 11a and central plate 11b.

[0037] The outer side of the top plate 12 has hanging ears 12a, the vibrator 17 is arranged horizontally, and the vibrator 17 is directly installed on the center plate 11b through bolts.

[0038] Such as Figure 5 As shown, there is only one filter cartridge 10 in the dust collector, the inner chamber of the dust collector is not divided into upper chamber 1a and lower chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com