Hydraulic automatic adjustment jaw crusher

A jaw crusher and automatic adjustment technology, applied in grain processing and other directions, can solve the problems of immovable jaw tension, low efficiency, air suction and negative pressure of tension cylinders and support cylinders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

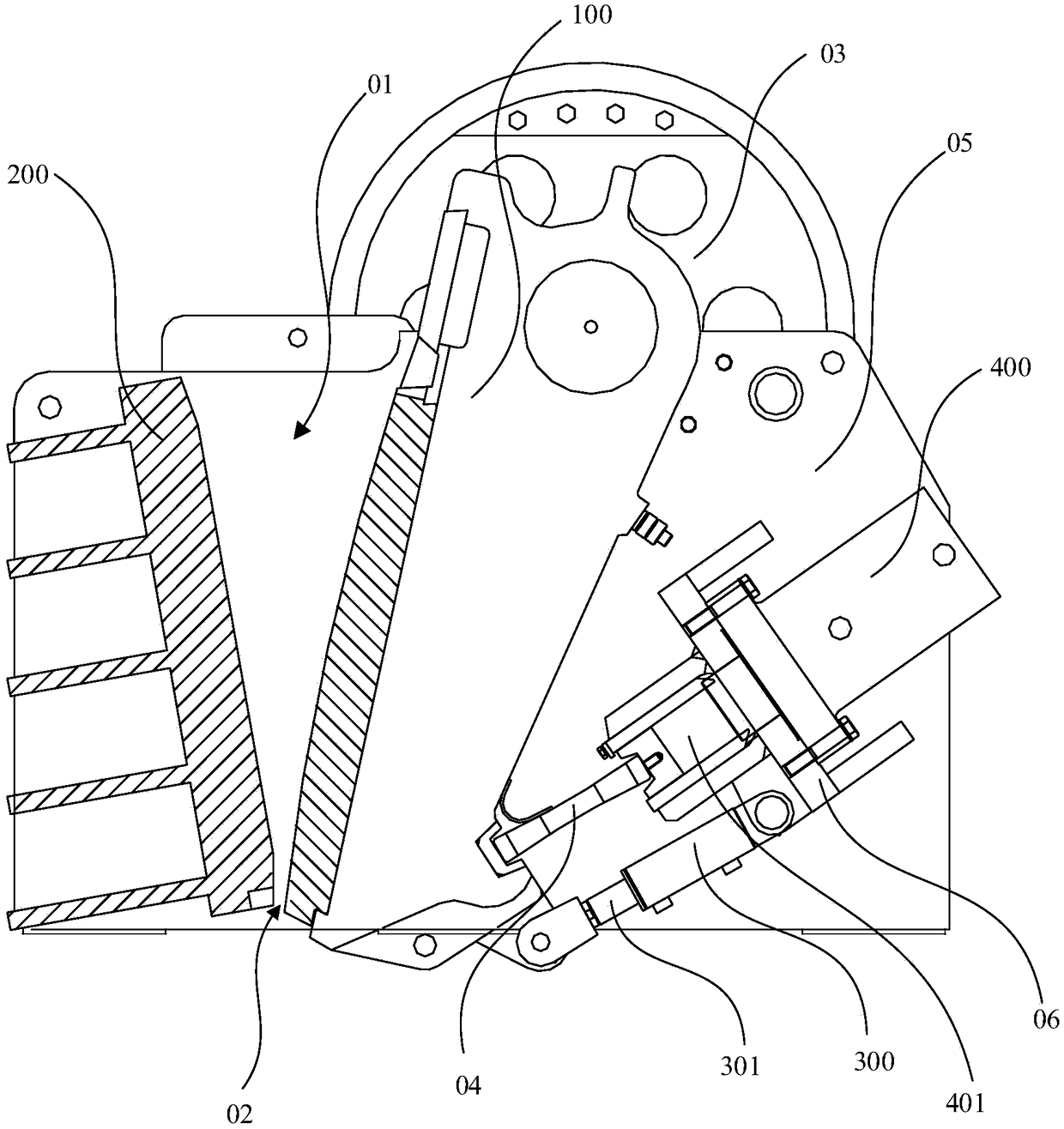

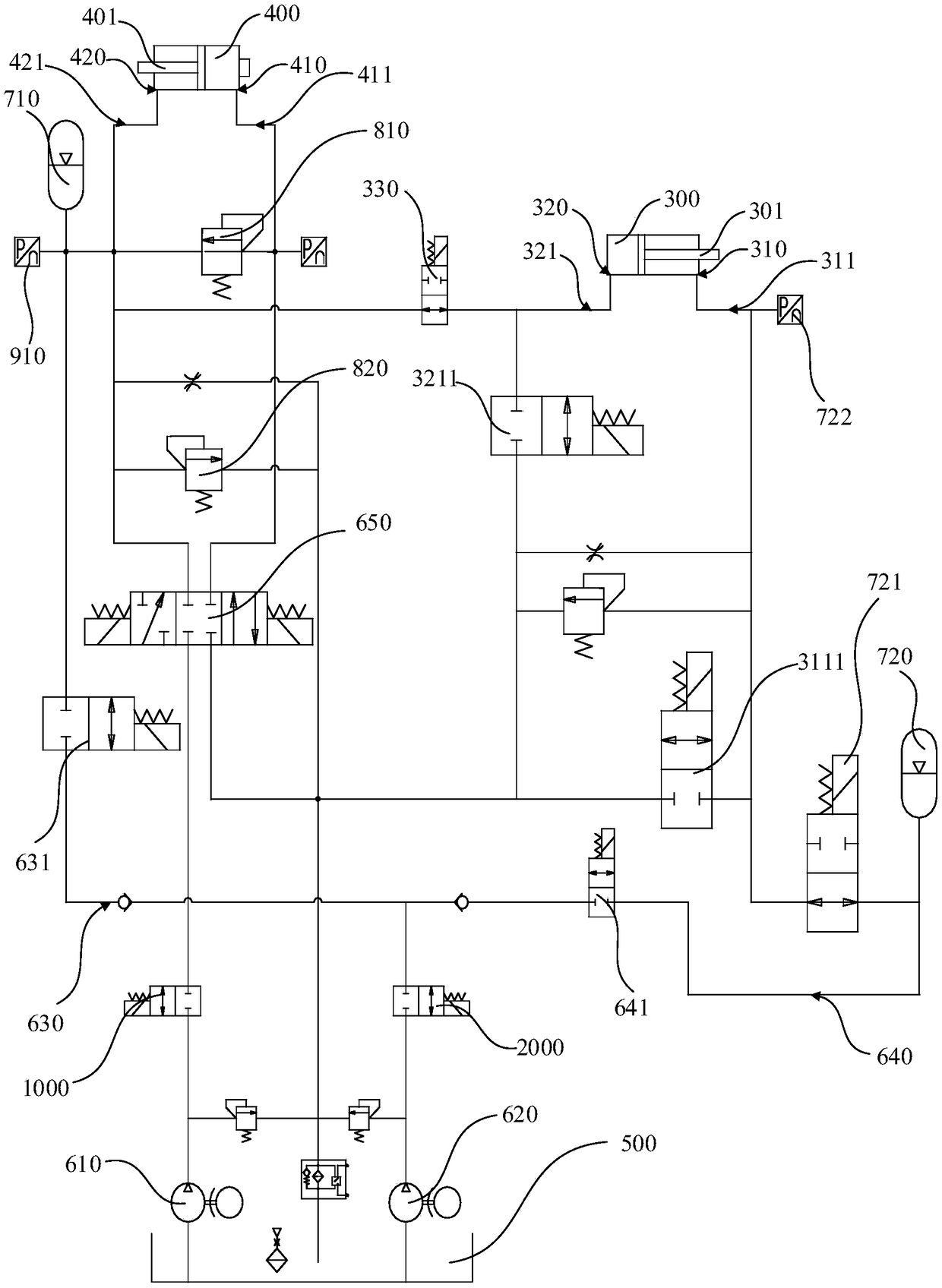

[0073] Such as figure 1 with figure 2 A hydraulic automatic adjustment jaw crusher is disclosed, which includes a movable jaw 100, a fixed jaw 200, a tightening cylinder 300, a supporting cylinder 400, an oil tank 500, a hydraulic pump 610, a supporting accumulator 710, and a tensioning accumulator 720 , support overflow valve 810 and energy storage overflow valve 820 . Among them, the hydraulic automatic adjustment jaw crusher also includes a casing 05 and a bracket 06, the fixed jaw 200 and the bracket 06 are fixed on the casing 05, the cylinder body of the supporting cylinder 400 is fixed on the bracket 06, and the tension cylinder The cylinder of 300 is connected to bracket 06.

[0074] Such as figure 1 As shown, a variable-sized crushing chamber 01 is formed between the movable jaw 100 and the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com