Eccentric-wheel-based variable-curvature bending method for metal pipe

A technology of metal pipe fittings and eccentric wheel, which is applied in the field of variable curvature bending of metal pipe fittings based on eccentric wheel, can solve the problems of reducing the forming quality and forming efficiency of metal complex curved pipe fittings, and the number of bending radii is limited, so as to improve the bending forming efficiency, The effect of reducing quantity and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with drawings and embodiments.

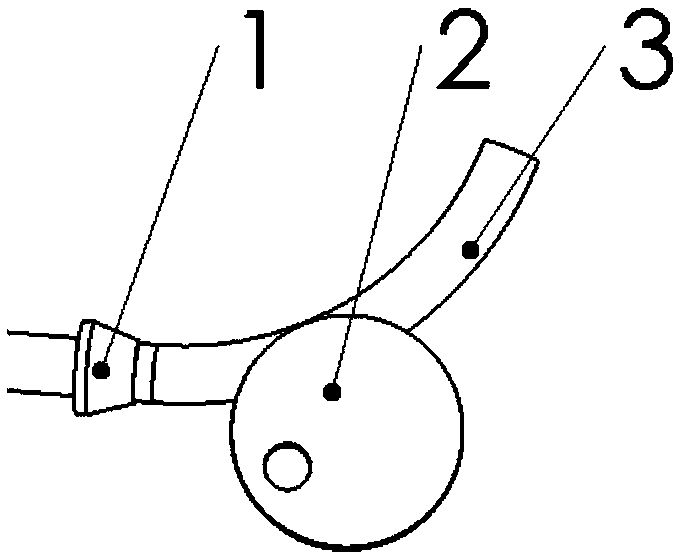

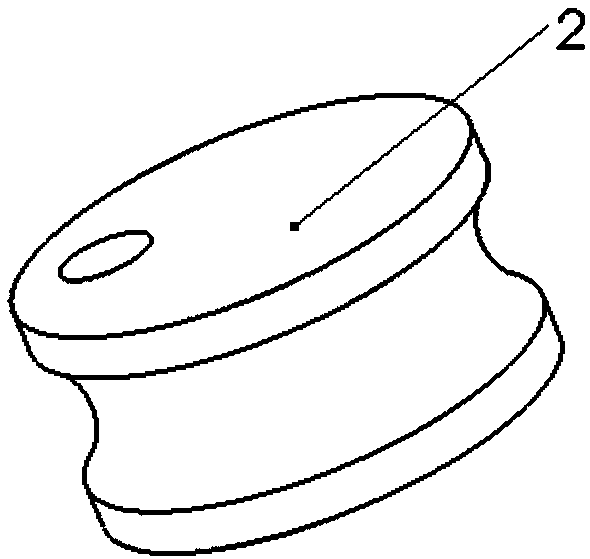

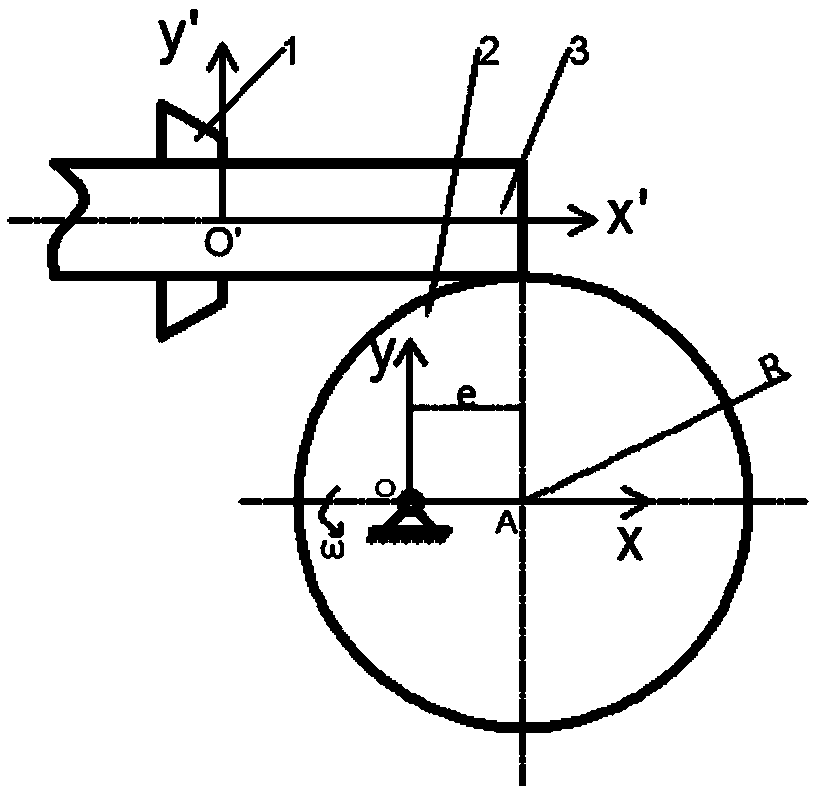

[0048] Such as figure 1 As shown, the specific implementation of the present invention includes a fixed bending die 1, an eccentric wheel free bending die 2 and a metal pipe fitting 3; bending die 2 such as figure 2 As shown, there is an annular groove in the middle, and the metal pipe fitting 3 is fed along the axis of the fixed bending die 1; during the bending and forming process of the metal pipe fitting 3, the position of the fixed bending die 1 is fixed, and the eccentric wheel is free to rotate the bending die 2 The center is located at its own eccentricity. The eccentric wheel free bending die 2 rotates around its own rotation center at a constant angular velocity and its own rotation center moves with a fixed trajectory. The fixed bending die 1 and the eccentric wheel free bending die 2 work together to realize the bending of the metal pipe 3 segment bending...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com