Machining Technology to Guarantee Position Tolerance of Main Hole System of Precision Box Parts of CNC Machine Tool

A technology of CNC machine tools and processing technology, which is applied in the field of processing technology to ensure the position tolerance of the main hole system of precision box parts of CNC machine tools, and can solve the problems that the processing accuracy cannot meet the design requirements, the accuracy error of the processing machine tool, and the long production cycle. Achieve the effect of ensuring the position tolerance of the main hole system of precision box parts, avoiding the influence of machining accuracy, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] combined with Figures 1 to 9 The specific embodiment of the present invention is described further:

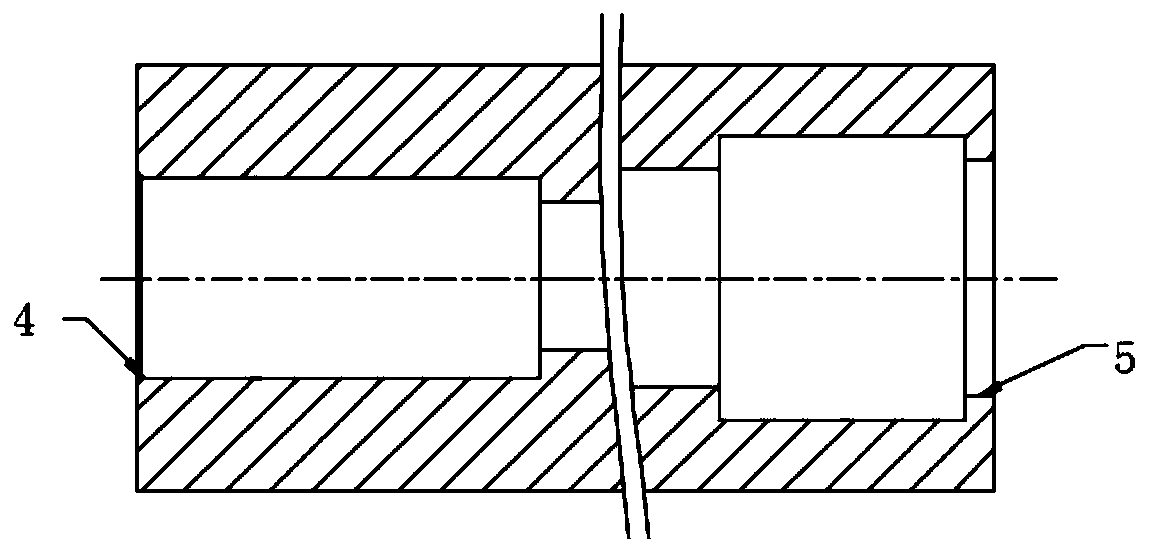

[0040] The position of the main hole system of precision box parts of CNC machine tools includes two opposite end faces with connected holes Ⅰ and Ⅱ (such as image 3 As shown, 4 is hole I and 5 is hole II. ).

[0041] A processing technology for ensuring the position tolerance of the main hole system of precision box parts of CNC machine tools, the processing technology includes the following steps:

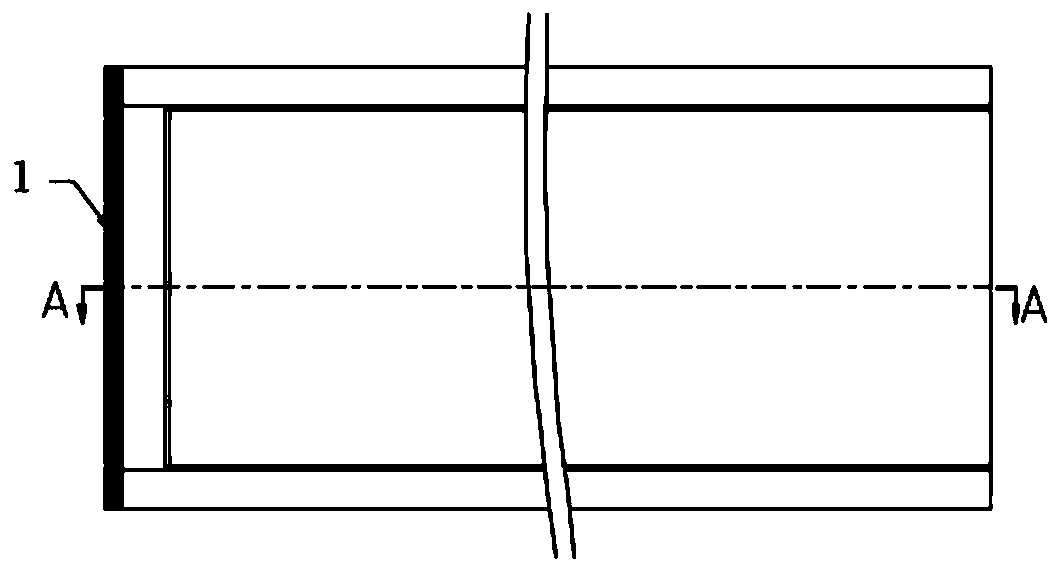

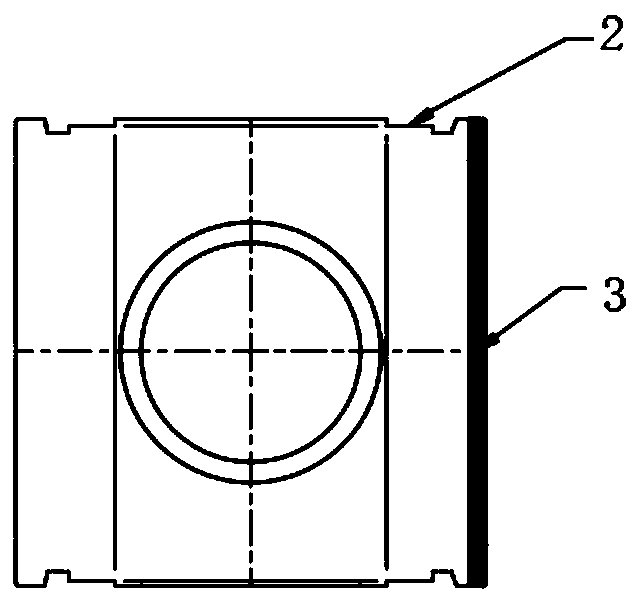

[0042] (1) Before the fine boring process, according to the position of the main hole system on the part, first process three process reference planes on the workpiece along the X, Y, and Z axes (such as Figure 1-3 As shown, the first process reference plane 1, the second process reference plane 2, and the third process reference plane 3. ).

[0043] The three process reference planes of the workpiece along the X, Y, and Z axes are determined as follows:

[0044] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com