Thin-wall barrel nesting device

A technology of thin-walled cylinders and suits, which is applied in the direction of hand-held tools and manufacturing tools, can solve the problems of long production cycle, easy deformation, large deformation, etc., and achieve the goals of reducing labor intensity, high degree of automation, and improving the quality of suits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described in detail below according to the embodiments and the accompanying drawings.

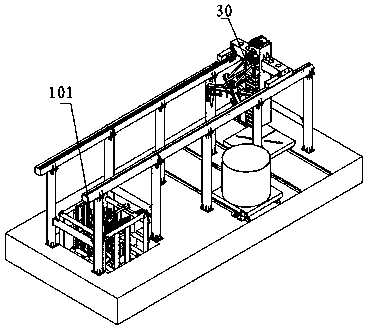

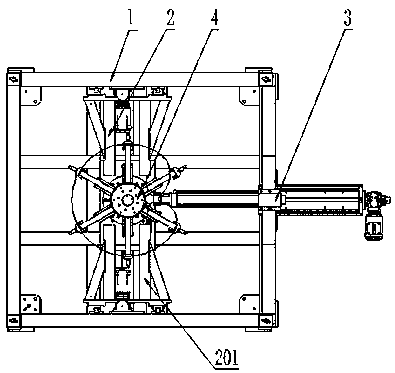

[0020] Such as figure 1 , figure 2 As shown, a thin-walled cylinder assembly device includes a set unit 101 and a transfer device 30, the transfer device 30 is arranged above the set unit 101, and the set unit 101 includes a frame 1, a jacking mechanism 2, Side pressing mechanism 3, telescopic lining mechanism 4, said telescopic lining mechanism 4 is arranged at the bottom of frame 1, said jacking mechanism 2 includes a pair of jacking assemblies 201 symmetrically arranged on both sides of telescopic lining mechanism 4 , the pair of jacking assemblies 201 are respectively connected to the upper and lower sides of the frame 1 , and the side pressing mechanism 3 is connected to the right side of the frame 1 .

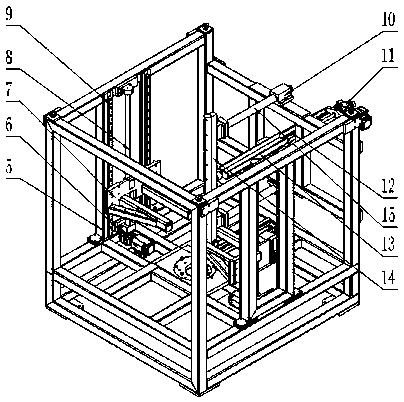

[0021] Such as image 3 As shown, the jacking assembly 201 includes a mounting seat 5, a first reduction moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com