Efficient and environmental-friendly wood chip treatment device for wood processing

A technology for processing equipment and wood chips, which is applied in wood processing equipment, manufacturing tools, solid separation, etc., can solve the problems of particle screening and increase the workload of operators, and achieve the effects of avoiding screening, improving practicability, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

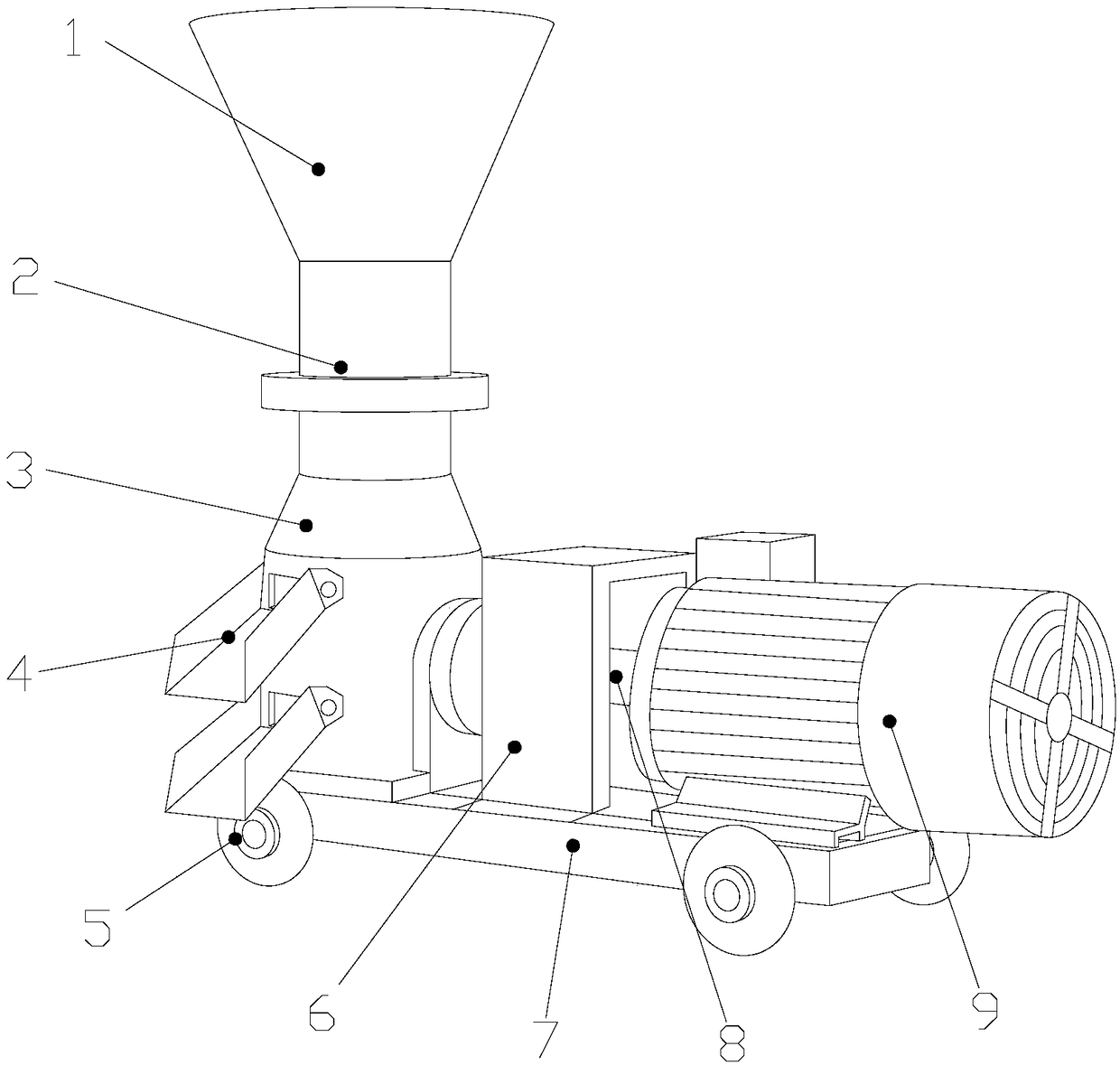

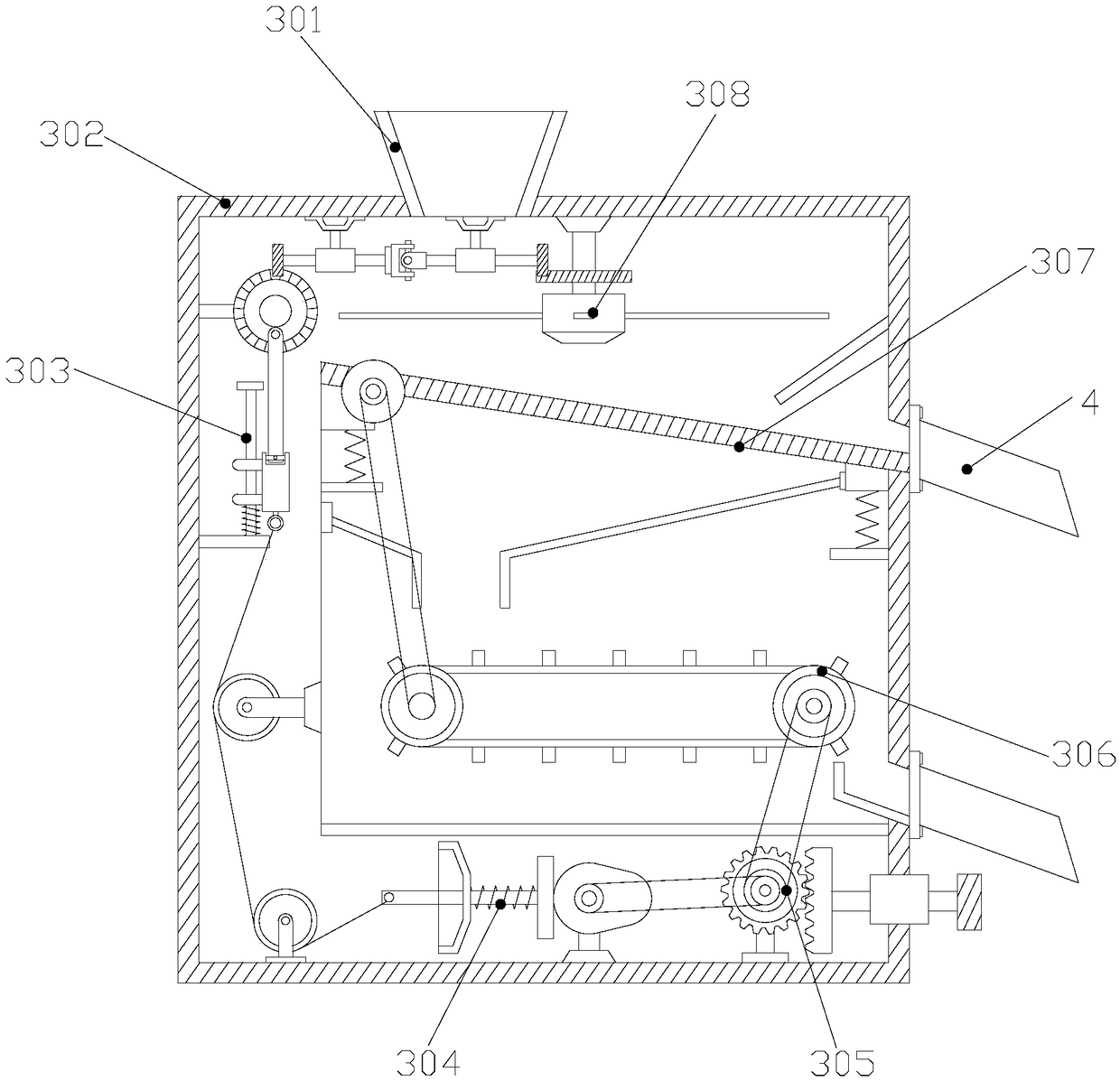

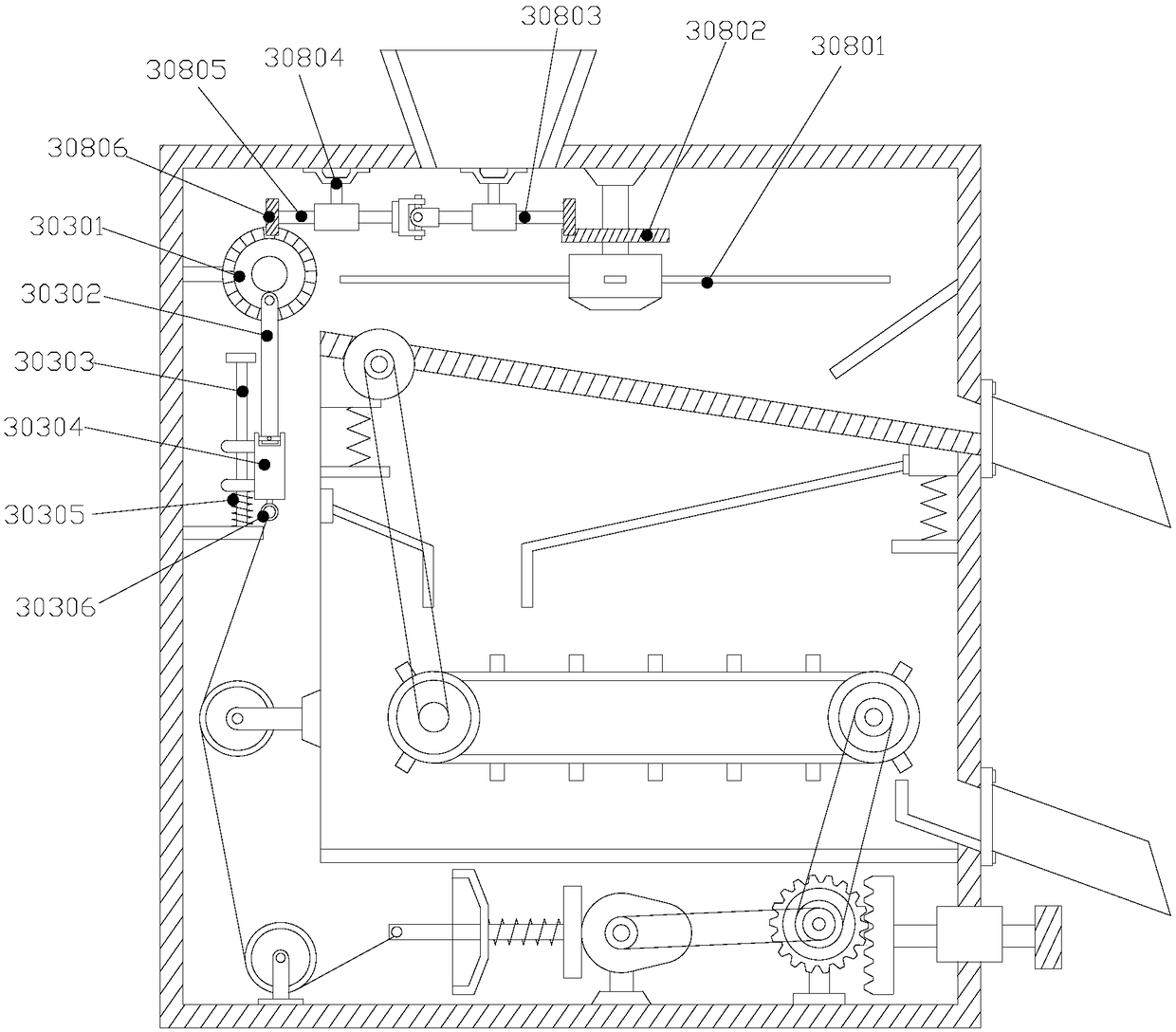

[0021] Such as Figure 1-Figure 5 As shown, the present invention provides a high-efficiency and environment-friendly sawdust treatment equipment for wood processing, the structure of which includes a sawdust feed hopper 1, a sawdust compressor 2, a particle screening device 3, a discharge hopper 4, a silent moving wheel 5, and a coupling protection Cover 6, equipment support base 7, coupling 8, drive motor 9, the silent moving wheel 5 bolts are fixed on the four corners of the bottom surface of the equipment support base 7, and the drive motor 9 is horizontally fixed on the right end of the upper surface of the equipment support base 7 , the coupling protection cover 6 is located on the left side of the drive motor 9 and is bolted together with the equipment support base 7, the particle screening device 3 is welded to the left end of the upper surface of the equipment support base 7, and the discharge hopper 4 is nested in the On the front of the particle screening device 3, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com