A Deviation Correction Reminder Applied to Corrugated Cardboard Production Line

A technology of corrugated cardboard and reminder device, which is applied in the direction of layered products, lamination, chemical instruments and methods, etc., can solve problems such as bonding deviation and unqualified corrugated cardboard, and achieve the effect of improving reminders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

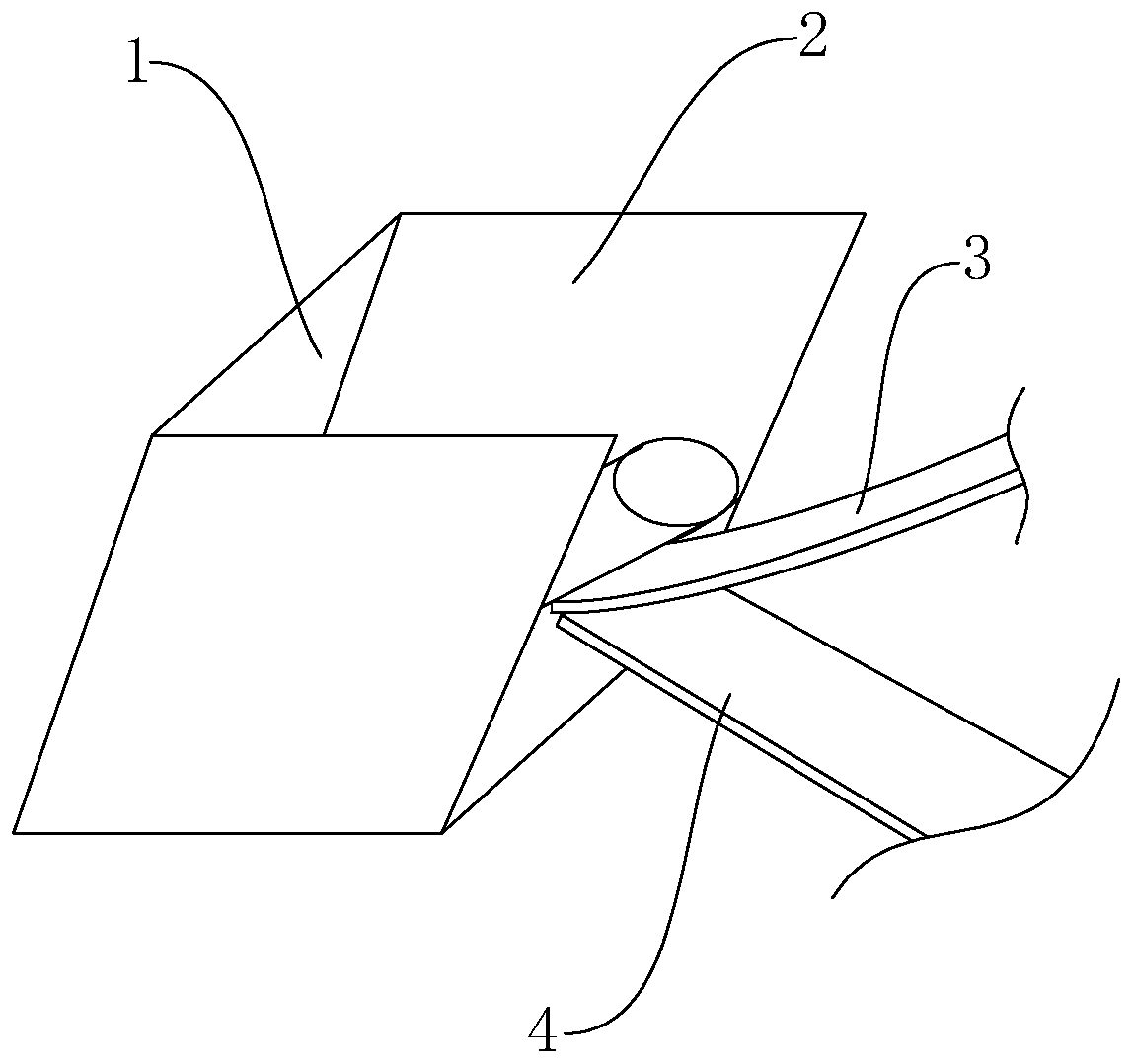

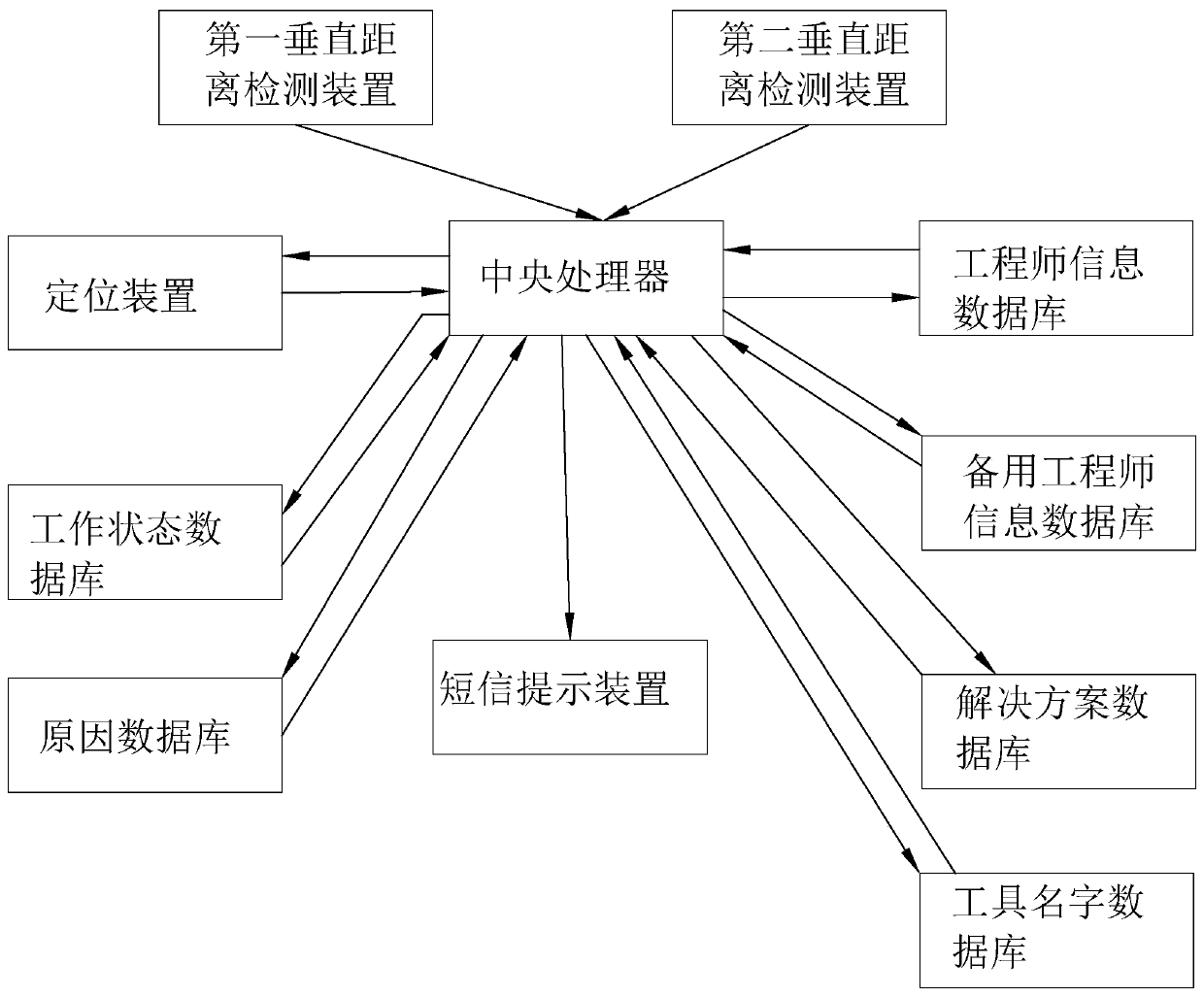

[0033] Such as figure 1 As shown, a deviation correction reminding device applied to a corrugated cardboard production line includes a central processing unit, including a panel 2 arranged on both sides of a single tile machine 1 to detect the vertical distance between the corrugated paper 4 and the panel 2 close to the corrugated paper 4 The first vertical distance detection device, the second vertical distance sensor for the vertical distance between the inner paper 3 and the panel 2 close to the corrugated paper 4, and the positioning device for locating the position of the single tile machine 1, storing the position of the positioning device in charge The engineer information database of the mobile phone number of the engineer who is in the maintenance work of the single tile machine 1, the short message prompting device, the first vertical distance detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com