Vibration stopping structure of container ship lashing bridge

A technology for container ships and lashing bridges, which is applied in the direction of the device for preventing multi-way movement of goods, etc. It can solve the problems of fatigue damage to the weld seam at the root of the lashing bridge, the reduction of the fastening degree of loose parts in lashing, and endanger the physical and mental health of passengers, etc., so as to improve the lashing The effect of improving the working environment, reducing the probability of binding failure events, and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

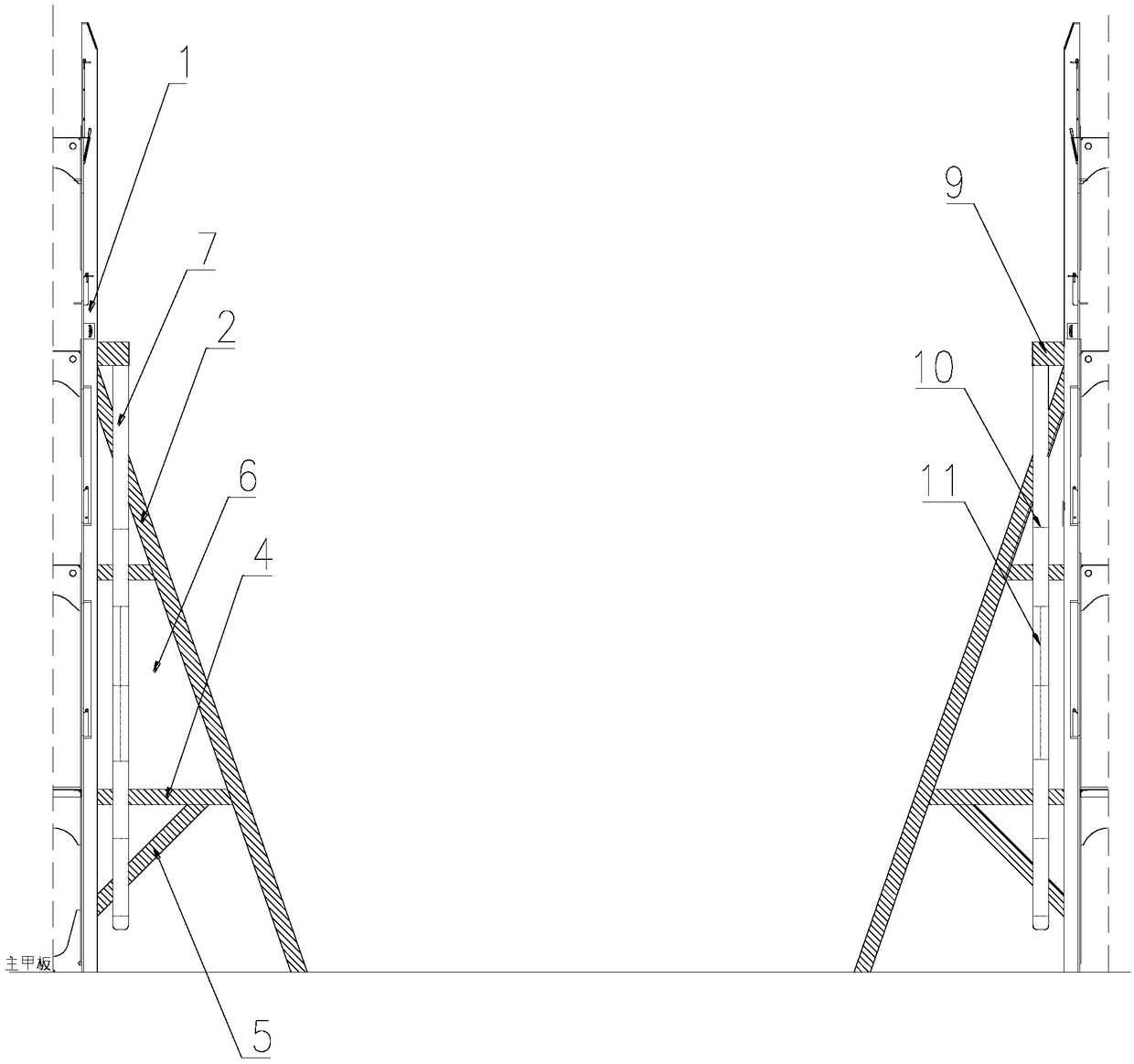

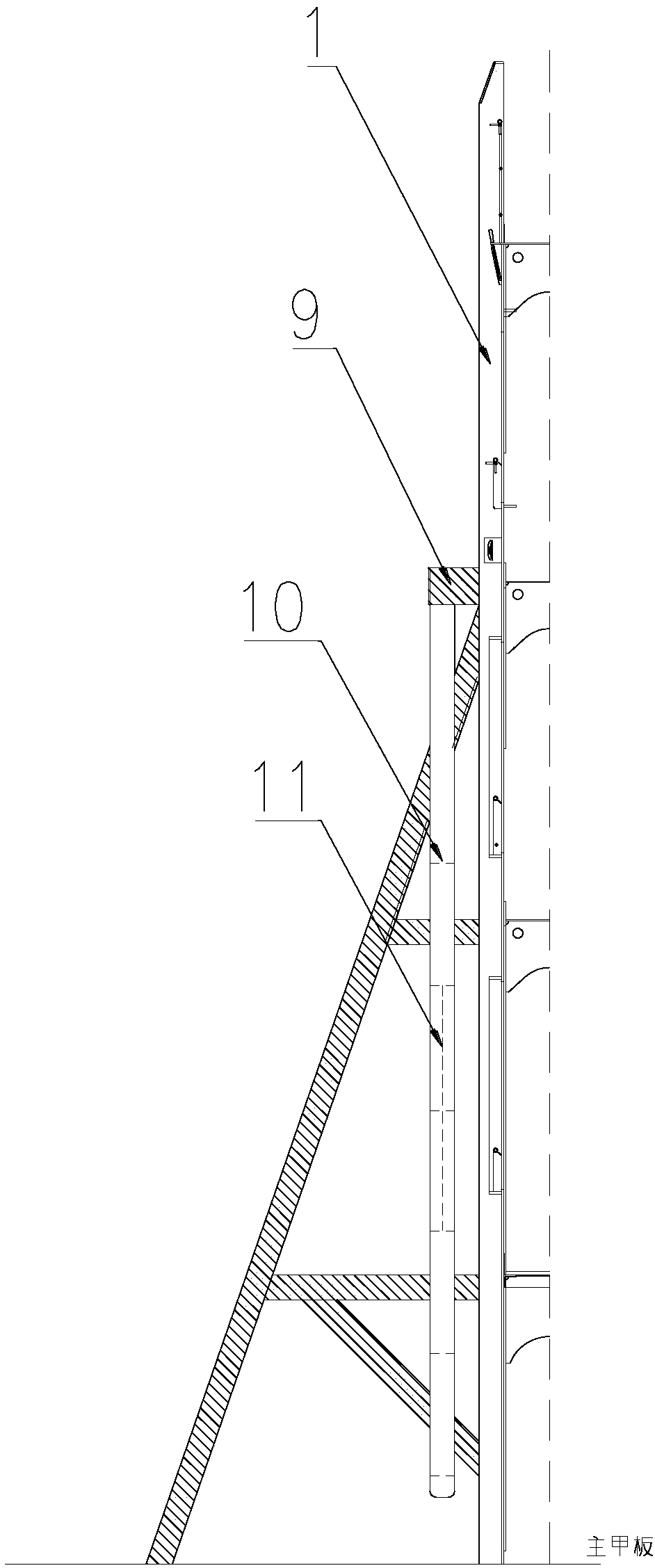

[0039] This embodiment includes two square tube brace brackets 2 fixedly connected with each other and symmetrical to each other between adjacent lashing bridges 1, and the two square tube brace brackets fall on the main deck. Because there is a support mechanism under the main deck, there is no need to design another support mechanism on the main deck. The square tube brace bracket 2 forms a triangular stable structure with the binding bridge 1 and the main deck, and the square tube brace bracket 2 is fixedly connected with the binding bridge 1 and the main deck by welding. An anti-collision guide rail device fixedly connected with it is arranged outside the square tube brace bracket 2 . At least one reinforced square tube is fixed between the square tube brace bracket 2 and the lashing bridge 1 , and the reinforced square tube is a transversely reinforced square tube 4 and / or an inclined plane reinforced square tube 5 . The hollow space formed by the square tube brace brack...

Embodiment 2

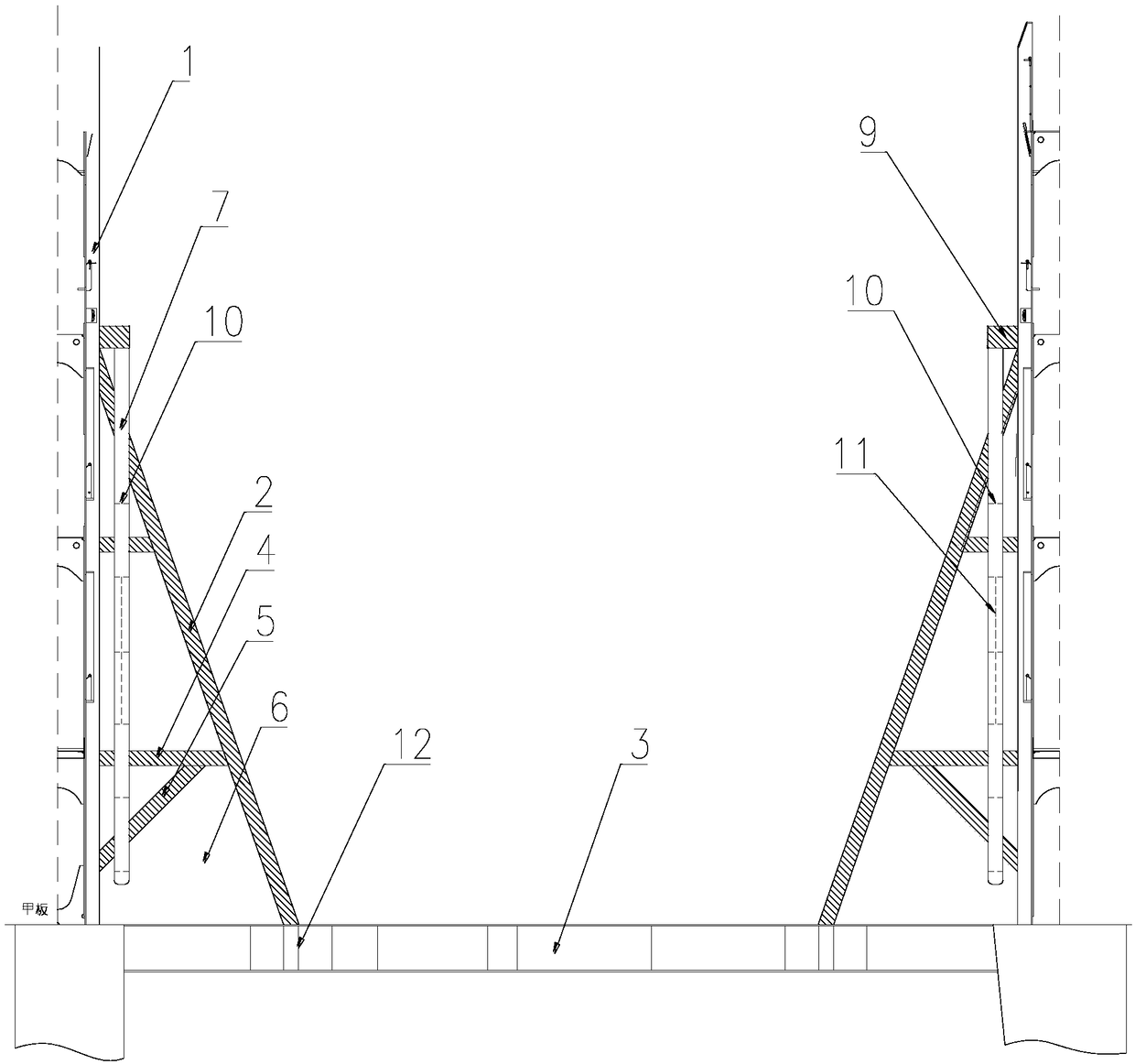

[0044] This embodiment includes two square tube brace brackets 2 that are fixedly connected to each other and are symmetrical to each other between adjacent binding bridges 1. Word beam 3 goes up. Because the bottom of the deck is empty, it is necessary to design an I-beam on the deck as a supporting mechanism. The I-beam 3 spans between the adjacent lashing bridges 1, and is fixedly connected to the deck by welding, and the upper plane of the I-beam 3 is on the same level as the upper plane of the deck; the square tube The diagonal brace bracket 2 forms a triangular stable structure with the binding bridge 1 and the I-beam 3 , and the square tube diagonal brace bracket 2 is fixedly connected with the binding bridge 1 and the I-beam 3 by welding. An anti-collision guide rail device fixedly connected with it is arranged outside the square tube brace bracket 2 . At least one reinforced square tube is fixed between the square tube brace bracket 2 and the lashing bridge 1 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com