Knitting machine dust removing device capable of lifting and changing rotating angle

A technology of rotation angle and dust removal device, applied in knitting, textile and paper making, etc., can solve the problems affecting dust removal effect and product quality, occupying space, disorder and other problems, and achieve the effect of protecting health, low noise and ensuring product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following examples are further explanations and supplements to the present invention, and do not constitute any limitation to the present invention.

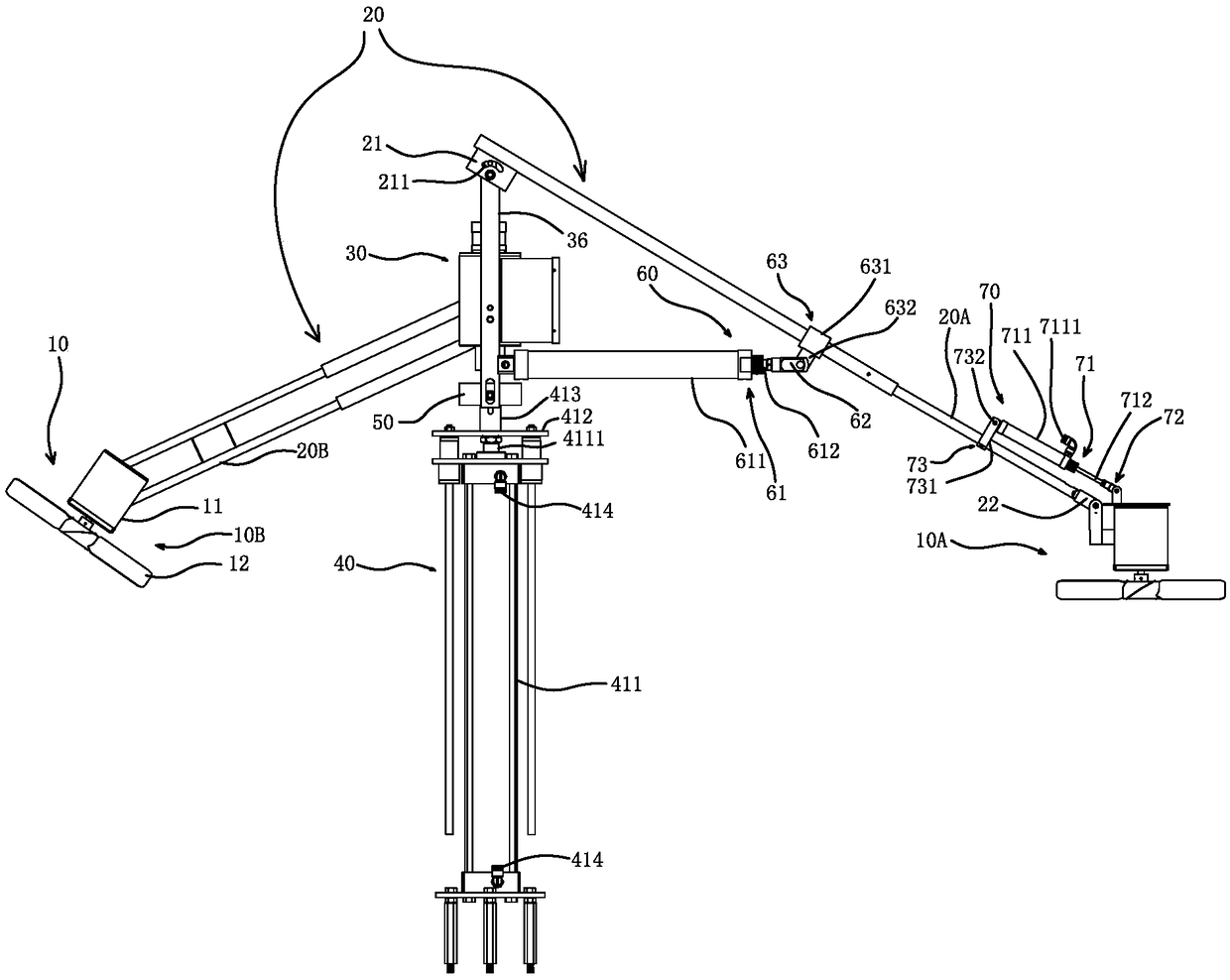

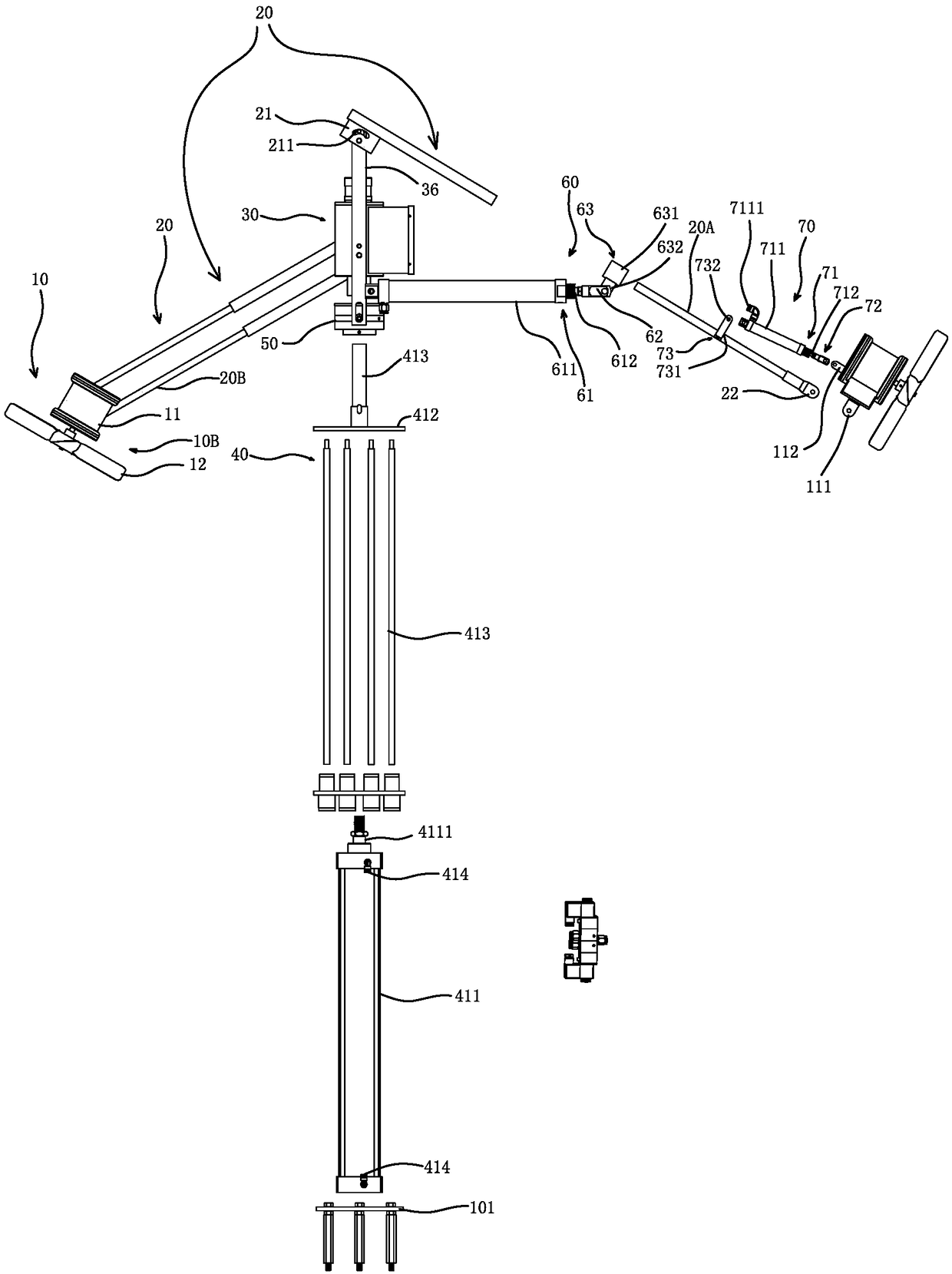

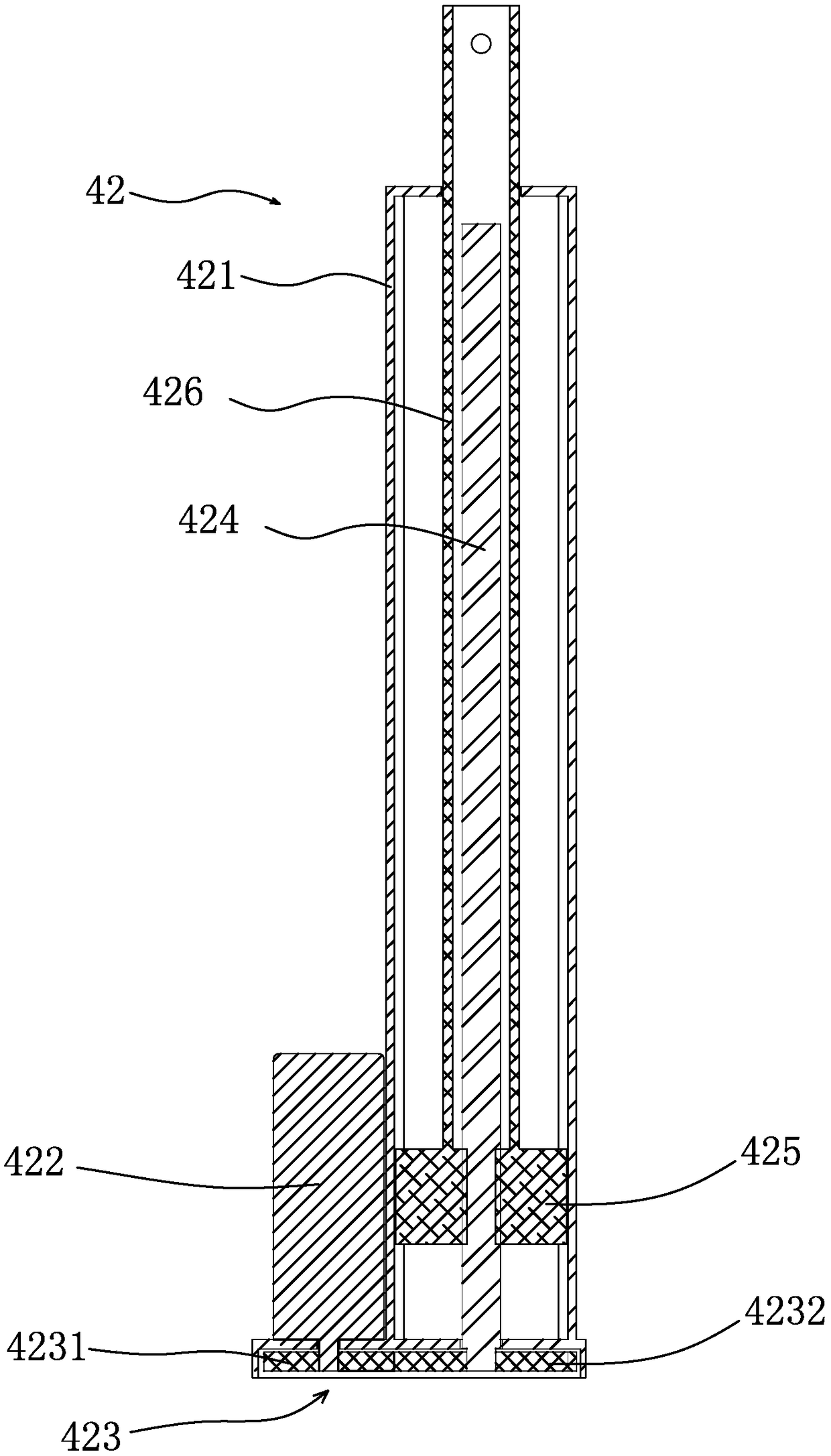

[0031] see figure 1 , figure 2 , the dust removal device for knitting machines that can lift and change the rotation angle of the present invention includes at least one set of dust removal fans 10, fan connecting rods 20, central rotating body 30, lifting mechanism 40, air intake rotating complex 50, fan connecting rod angle change The mechanism 60 , the fan angle conversion mechanism 70 and the control mechanism 80 .

[0032] like Image 6 , Figure 7 As shown in the figure, the dust removal device for the knitting machine of the present invention, which can be raised and lowered and the rotation angle can be changed, is arranged in the center of the yarn feeder disc above the machine table of the knitting machine. D, yarn hook E and other parts to remove dust. After lifting, the air duct B and other ducts C c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com