Sealing ring for valve base of high-pressure double-piston combination type normal temperature ball valve

A dual-piston, combined technology, used in valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of unprotected lip of the sealing ring, non-functioning of the sealing ring, easy breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

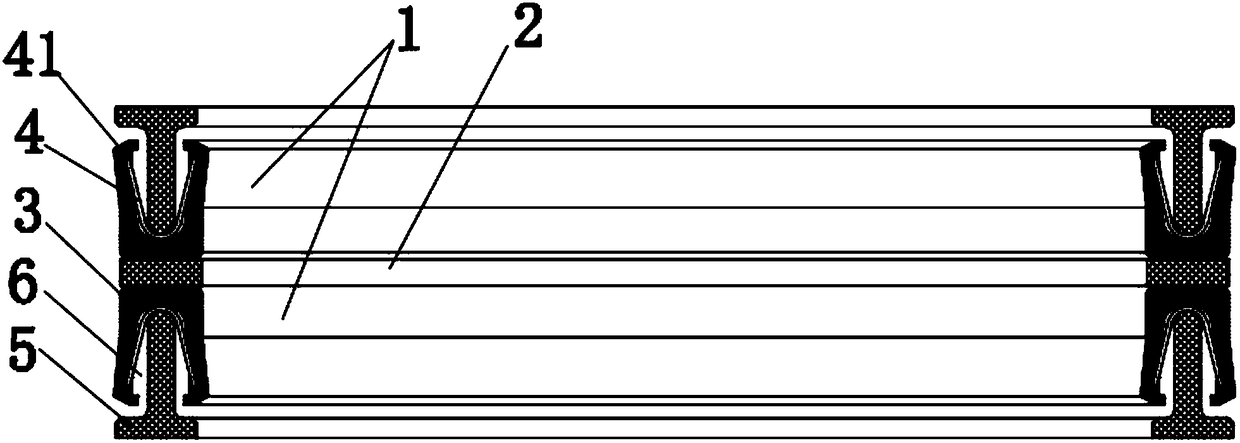

[0018] like figure 1 As shown, the present invention discloses a high-pressure dual-piston combined normal temperature ball valve seat sealing ring, which includes two sets of sealing assemblies 1 arranged symmetrically up and down, a retaining ring 2 is arranged between the two sets of sealing assemblies 1, and the sealing Assembly 1 includes a U-shaped PTFE jacket 3, a V-shaped leaf spring 4 and a T-shaped pressure ring 5. The top surface of the U-shaped PTFE jacket 3 is provided with a U-shaped ring groove 6. The U-shaped PTFE clamp The sleeve 3 includes two inner buckle lips 41 located at both ends and distributed symmetrically. The V-shaped leaf spring 4 is installed on the U-shaped ring groove 6 and engaged with the inner buckle lips 41. The T-shaped pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com