Magnetic-pump sealing plate with arc-shaped end face

A sealing plate and magnetic pump technology, which is applied to pump components, variable displacement pump components, components of pumping devices for elastic fluids, etc., can solve problems such as short service life, poor pressure bearing capacity of end faces, and easy damage , to achieve the effect of improving performance, strong pressure bearing capacity and strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

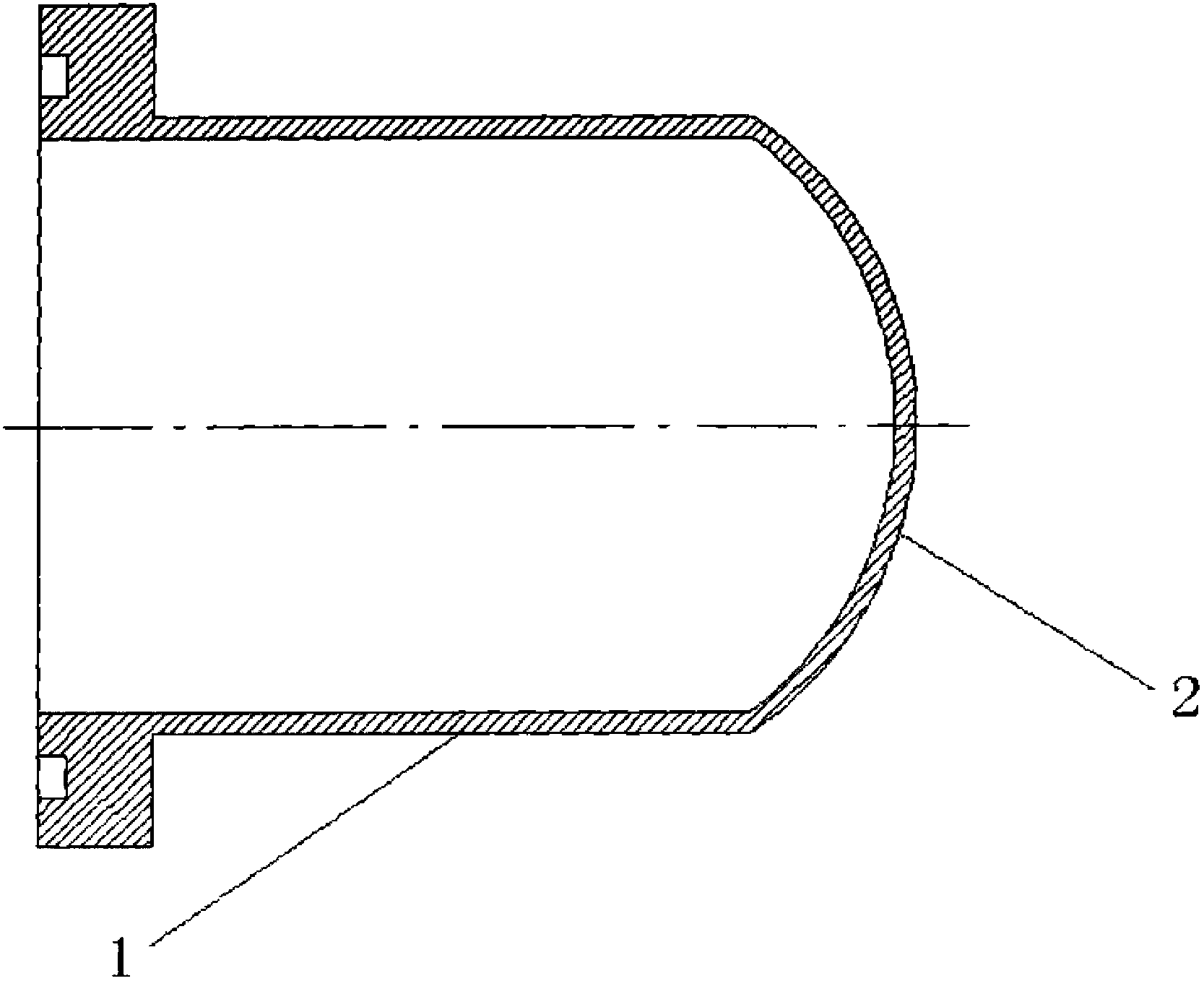

[0010] As shown in Figure 1, a sealing plate of a magnetic pump with an arc-shaped end face includes a sealing plate body, and the sealing plate body includes a cylindrical surface 1 and a 60° arc-shaped surface 2. The 60° arc-shaped surface 2 which is an arc-shaped surface can relieve the impact force of the water flow to a certain extent, and the pressure bearing capacity of such a structure is strengthened, so that the sealing plate can withstand the pressure of the water flow for a long time and prolong the service life. The sealing plate body is made of engineering plastic high-density polyethylene, which has strong physical and mechanical properties. The sealing plate body made of this material replaces the traditional metal sealing plate, which not only reduces cost and weight , At the same time, it can solve the heating problem of the magnetic eddy current. The magnetic field line cutting movement between the inner and outer magnetic rotors of the magnetic pump does not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com