Intelligent spherical support for spot welding

A spherical bearing and spot welding technology, which is applied to force/torque/work measuring instruments, bridge parts, measuring devices, etc., can solve the problems of bearing structure damage, complicated operation, large measurement error, etc., and achieve easy installation and replacement , accurate measurement method, real-time monitoring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

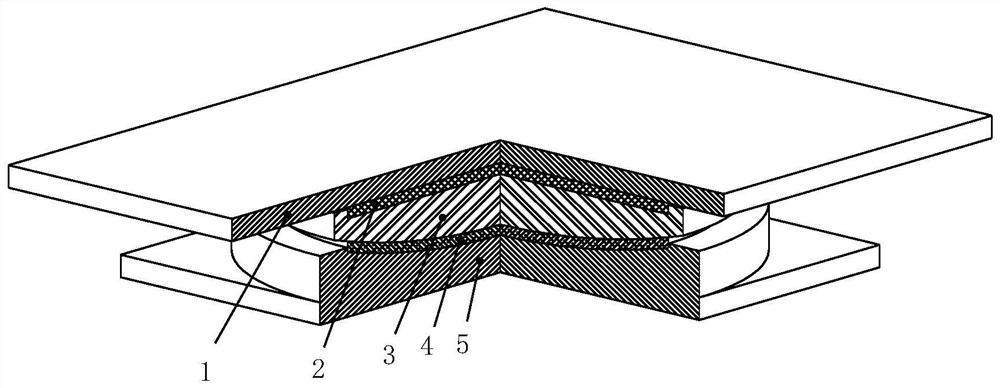

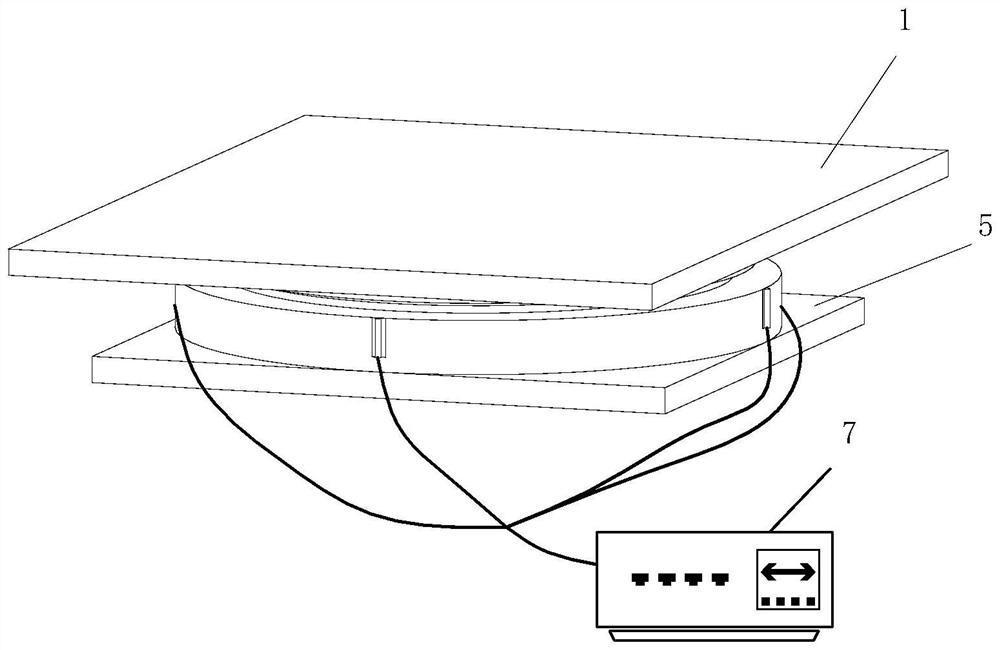

[0027] refer to Figure 1-4 , the present invention provides a spot welding intelligent spherical bearing, comprising an upper bearing plate 1, the top of the upper bearing plate 1 is in contact with the beam body of the bridge, and the bottom of the upper bearing plate 1 is provided with a lower bearing plate 5, The bottom of the lower support plate 5 is firmly connected to the pier, a spherical crown is provided between the lower support plate 5 and the upper support plate 1, and the measuring instrument 7 is electrically connected to the spot welding sensor 6, which is used for measuring points The load-bearing pressure of the welding intelligent spherical bearing, the lower bearing plate 5 is provided with a basin ring, the spot welding sensor 6 is vertically arranged on the outer wall of the basin ring, the outer side of the lower bearing plate 5 is provided with a measuring instrument 7, and the spot welding sensor 6 and measuring instrument 7 are electrically connected....

Embodiment 2

[0038] The difference from Example 1 is that, referring to Figure 5 :

[0039] The outer wall of the spherical crown steel liner 3 is fixed with four laterally arranged spot welding sensors 6 at equal intervals in the circumferential direction.

[0040] To further optimize the scheme, the spot welding sensor 6 is integrated with the support structure, and the spot welding sensor 6 is fixed on the outer side of the spherical crown steel lining plate 3 by welding, and four spot welding sensors can be measured and calculated at the same time by connecting the wire and the measuring instrument 7 The average value can improve the accuracy and reliability of detection, and it is easy to install and replace, without causing damage to the structural performance of the support, and can realize long-term and real-time monitoring of the stress on the support.

[0041] To further optimize the scheme, the spot welding sensors 6 on the outside of the spherical crown steel lining plate 3 o...

Embodiment 3

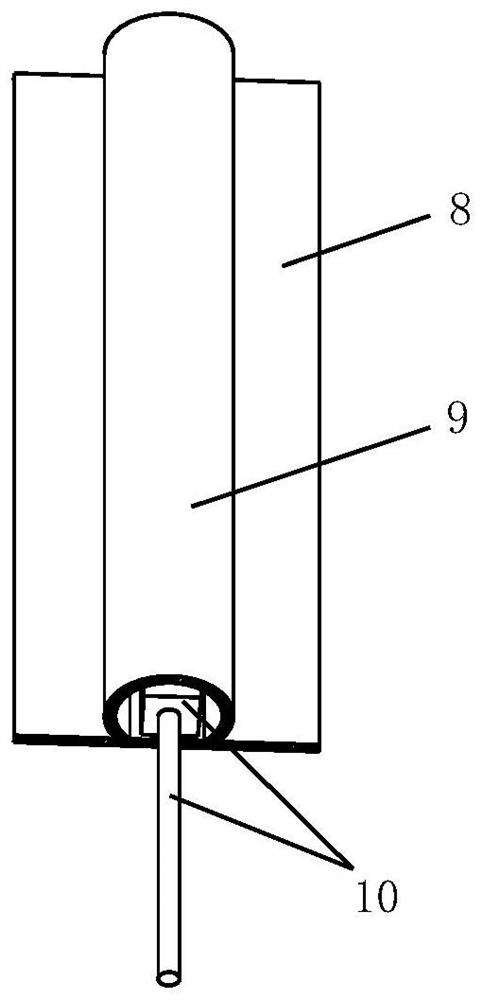

[0043] The difference from Example 1 and Example 2 is that, referring to Figure 6 :

[0044] The top surface of the upper support plate 1 is respectively provided with a welding hole and a lead groove, the welding hole is arranged at the center of the upper support plate 1, the lead groove communicates with the welding hole, and two spot welding sensors 6 are vertically welded in the welding hole, and the point The signal output end of the welding sensor 6 is connected with a wire, and the wire is connected to the measuring instrument 7 through the lead groove, and the data measured by the spot welding sensor 6 can be obtained through the measuring instrument 7 .

[0045] By measuring the average value of 2 spot welding sensors 6 and monitoring the force of the spherical bearing, the measurement method is more accurate and effective, and the force measuring system of this spot welding intelligent spherical bearing is easy to install and replace, and will not affect the spheri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com