Reactor protection system in-service inspection device

A reactor protection and inspection device technology, applied in reactors, nuclear reactor monitoring, greenhouse gas reduction, etc., can solve problems such as insufficient anti-interference ability and inspection accuracy, unfavorable for timely discovery of protection systems, complex structure of inspection devices, etc., to achieve The effect of short inspection cycle, convenient maintenance and debugging, and flexible parameter setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

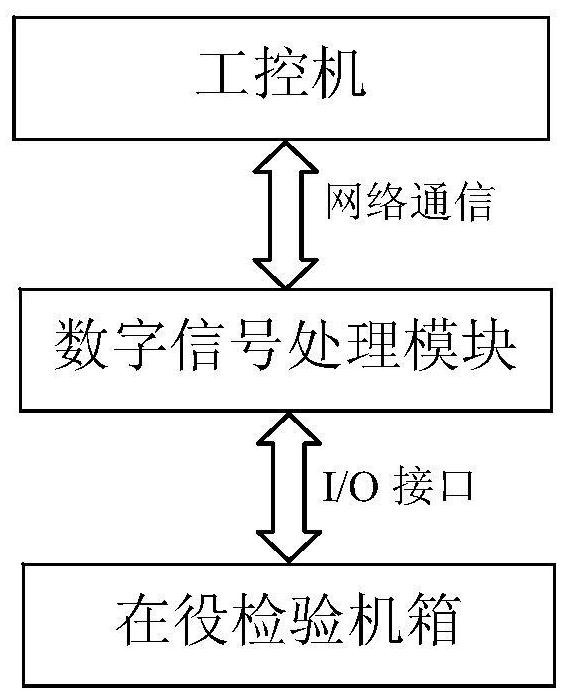

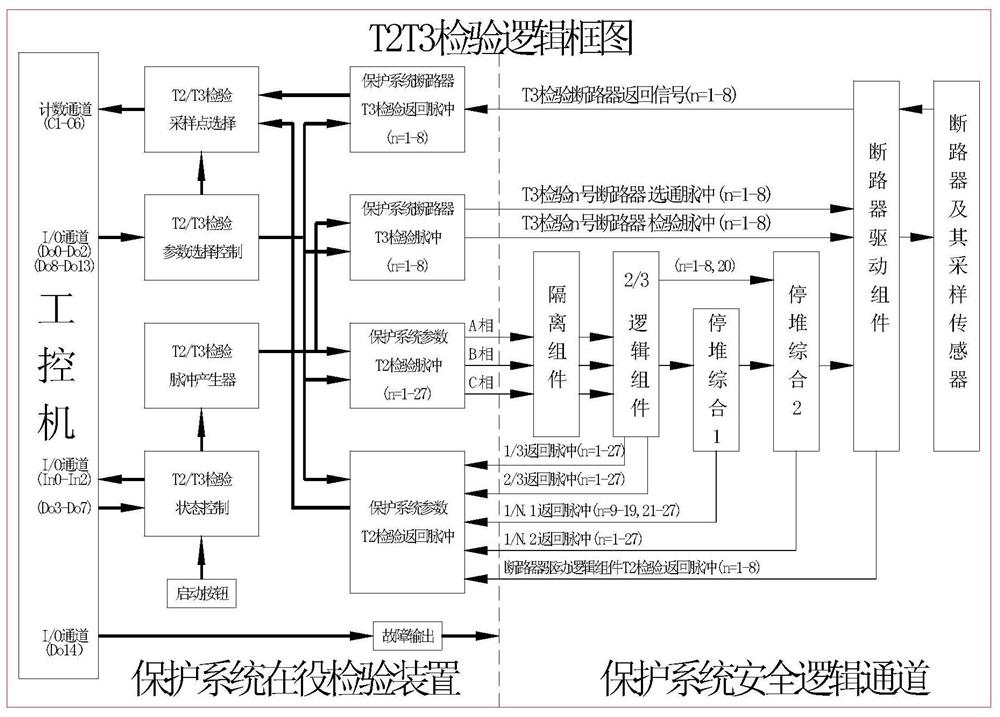

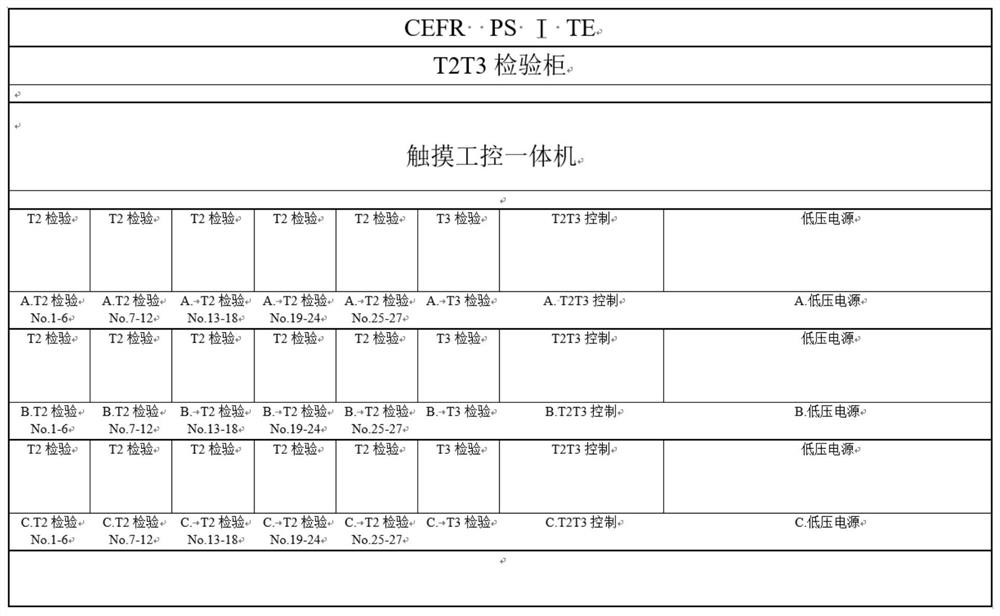

[0018] The reactor protection system T2 and T3 in-service inspection device hardware platforms provided by the present invention are built with NI digital signal processing module and industrial computer (touch all-in-one computer) as the core, such as figure 1 shown. The touch all-in-one computer and the digital signal processing module perform network communication (wired or wireless) based on the TCP / IP protocol to exchange data. Through the I / O interface on the NIcDAQ-9188 chassis of the digital signal processing module, the connection and communication between the digital signal processing module and the T2 and T3 in-service inspection chassis are realized. Finally, through the developed software, the selection of relevant plug-ins and parameters for T2 and T3 inspections can be realized, and the corresponding inspection logic can be realized. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com