Tray type bridge stand capable of being spliced

A tray type, bridge technology, applied in the direction of electrical components, etc., can solve the problems of weak bending resistance, safety hazards, increased cable laying expenses, etc., to achieve strong corrosion resistance, enhanced stability, and good general performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A splicable tray-type bridge frame of the present invention will be described in detail below in conjunction with the accompanying drawings.

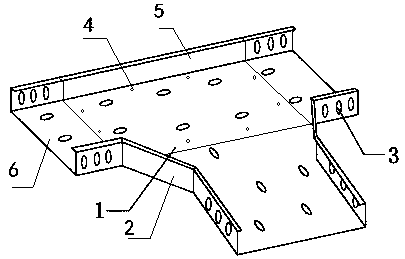

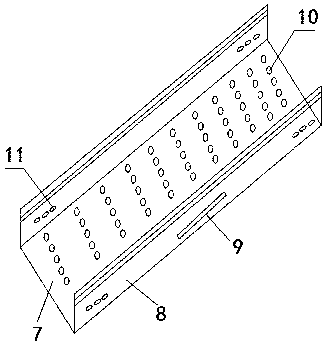

[0016] Such as figure 1 and figure 2 As shown, a splicable tray-type bridge frame includes a body seat 1 with ventilation holes at the bottom, four sets of screw holes 4 around the body seat 1, and second connecting seats 6 fixed on both sides of the body seat 1 with screws. , use screws to fix the first connecting seat 2 on the right side of the body seat 1, use screws to fix the baffle plate 5 on the left side of the body seat 1, and use fastening screws to connect the single frame on the second connecting seat 6; The single seat includes a bottom plate 7 with ventilation holes 10 at the bottom, a side plate 8 on the side of the bottom plate 7, a second connection port 11 is provided on both sides of the side plate 8, and a reinforcing rib 9 is provided outside the middle of the side plate 8; The inner side of the first conn...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap