Novel livestock and poultry feed production apparatus

A technology for production equipment and poultry, which is applied in feed, food science, application, etc., can solve the problems of unstable plugging force, easy generation of electric arc, casualties, etc., to achieve convenient automatic plugging and connection, and prevent dust from entering , Increase the effect of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

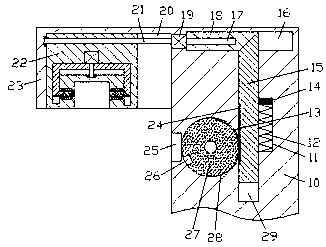

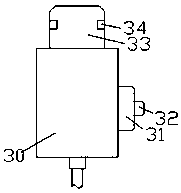

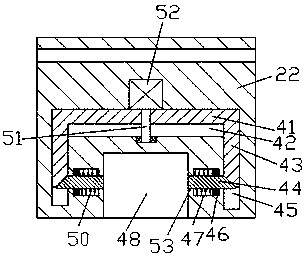

[0015] Combine below Figure 1-4 The present invention will be described in detail.

[0016] refer to Figure 1-4 , according to an embodiment of the present invention, a new type of livestock feed production device includes a main body 10 and a joint 30 installed on the main body 10, and a bump 23 is fixed on the top of the left end surface of the main body 10 , the bottom end surface of the protrusion 23 is provided with a first sliding groove 20, and a first sliding block 22 is installed in the first sliding groove 20, and a first sliding block 22 is installed in the bottom end surface of the first sliding block 22. There is a first socket 48, the inner walls of the left and right sides of the first socket 48 are symmetrically provided with locking devices, and the first sliding block 22 is threadedly fitted with a first screw-shaped rod 21, and the first screw-shaped rod 21, the left extension end is rotationally connected with the left inner wall of the first sliding gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com