Variable angle suitcase pull bar

A suitcase and trolley technology, which is applied in the field of bags, can solve the problems of unilateral wear and inconvenient use of the pulley of the suitcase, and achieve the effect of reducing wear, reducing force and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The present invention will be further described below through specific embodiments.

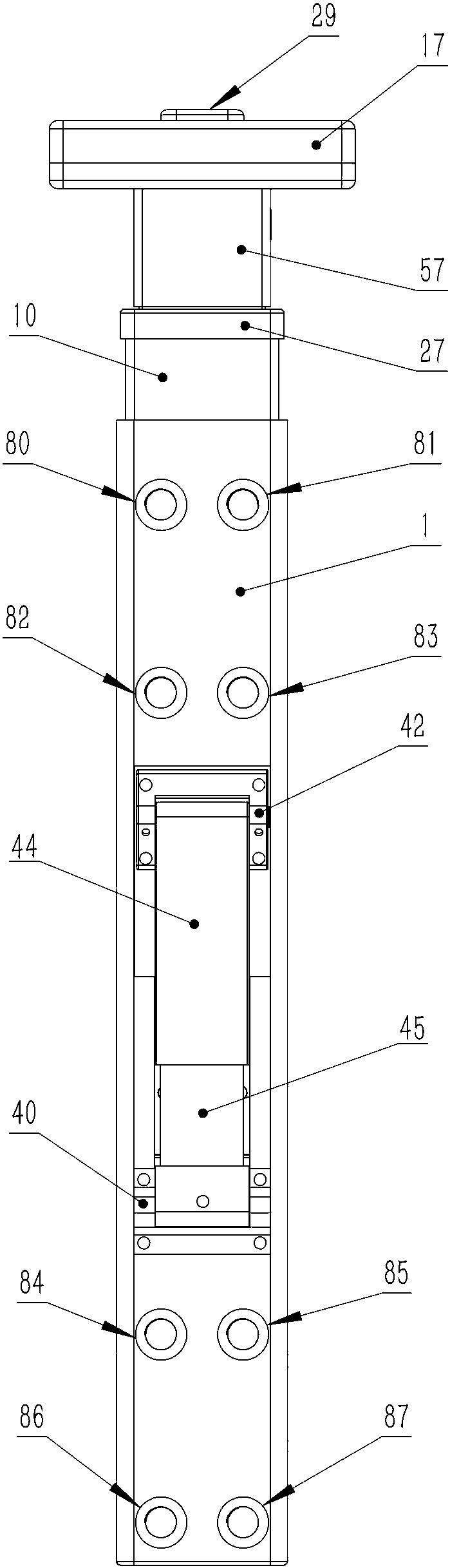

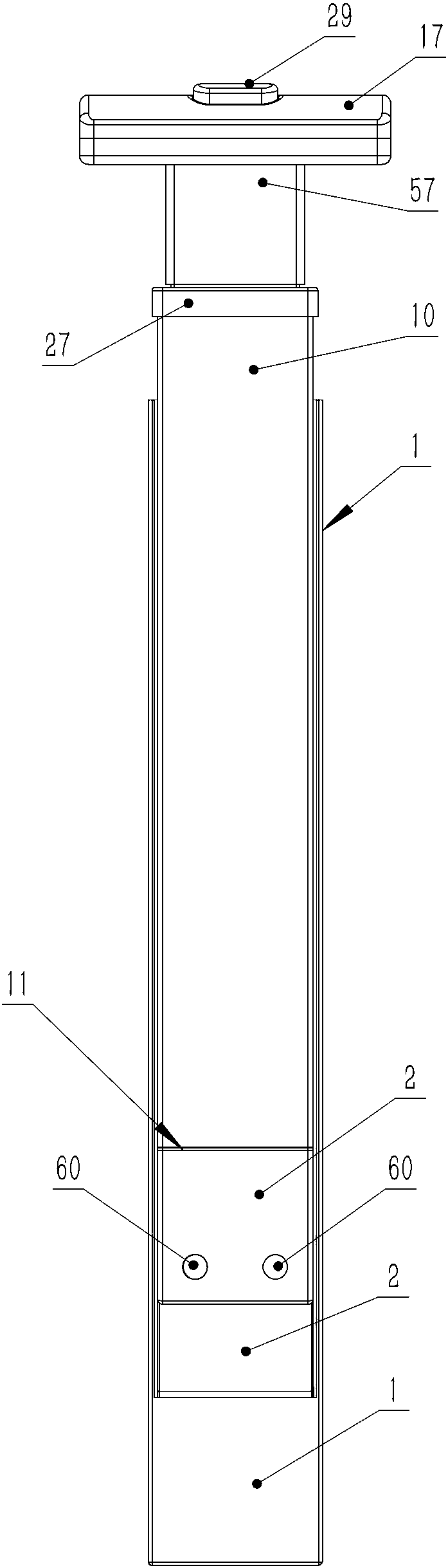

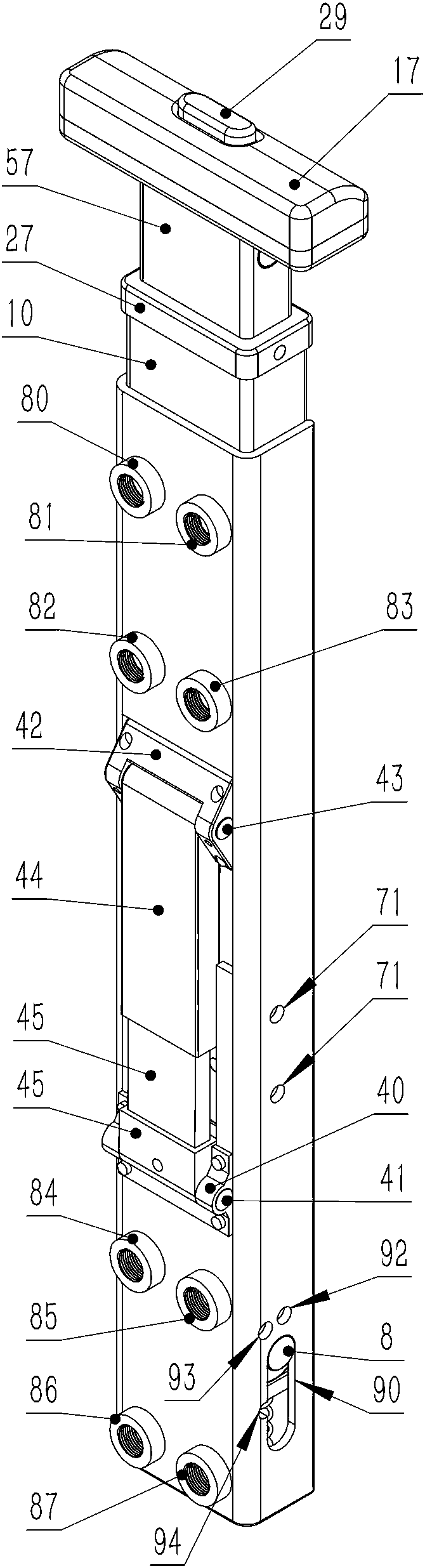

[0053] Reference Figure 1 to Figure 13 , A variable-angle suitcase pull rod, comprising a fixed pull rod housing (1), a rotating shaft housing (2), and a pull rod one (10) housing nested on the rotating shaft housing (2), a pull rod one (10) and a rotating shaft housing (2) There is an apron (11) in the joint gap between the two rods (12) is located in the shell of rod one (10), the handle bottom shell (57) of the rod is fixed to the rod two by the handle bottom shell fixing screw (24) (12) At the upper end of the housing, the handle surface shell (17) is fastened to the lever handle bottom shell (57) through the handle bottom shell fixing screw (103) and the lever button (29) is placed in the button hole of the lever handle surface shell (17) In position, there is a built-in button spring (38) in the inner center of the button (29) with one end in contact with the inner side of the butt...

Embodiment 2

[0058] Reference Figure 14 to Figure 16 , A variable-angle suitcase trolley, the structural design includes a suitcase trolley that can provide variable angles, while telescoping and adjusting the length. The extension and steering of the trolley are controlled by a mechanical control lock, and the core mechanism lock is modularized. This embodiment The difference between the second embodiment and the first embodiment is that the diagonal support sleeve and the diagonal support moving rod assembly are connected to the pull rod at an obtuse angle. The shaft end of the diagonal support sleeve is rotatably connected to the upper end of the fixed housing of the pull rod. The connection method and implementation The effect produced by the first example is similar, and the installation and fixing methods of the tie rod and the suitcase in the first and second embodiments are exactly the same.

[0059] The other structures in this embodiment are the same as those in the first embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com