Shoe cleaning mechanism

A technology for cleaning mechanisms and shoes, which is applied to cleaning equipment, cleaning of boots and shoes, household cleaning devices, etc., can solve problems such as high requirements for cleaning and sanitation, unsanitary public slippers, etc., to ensure cleaning effect, simple structure, and use effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

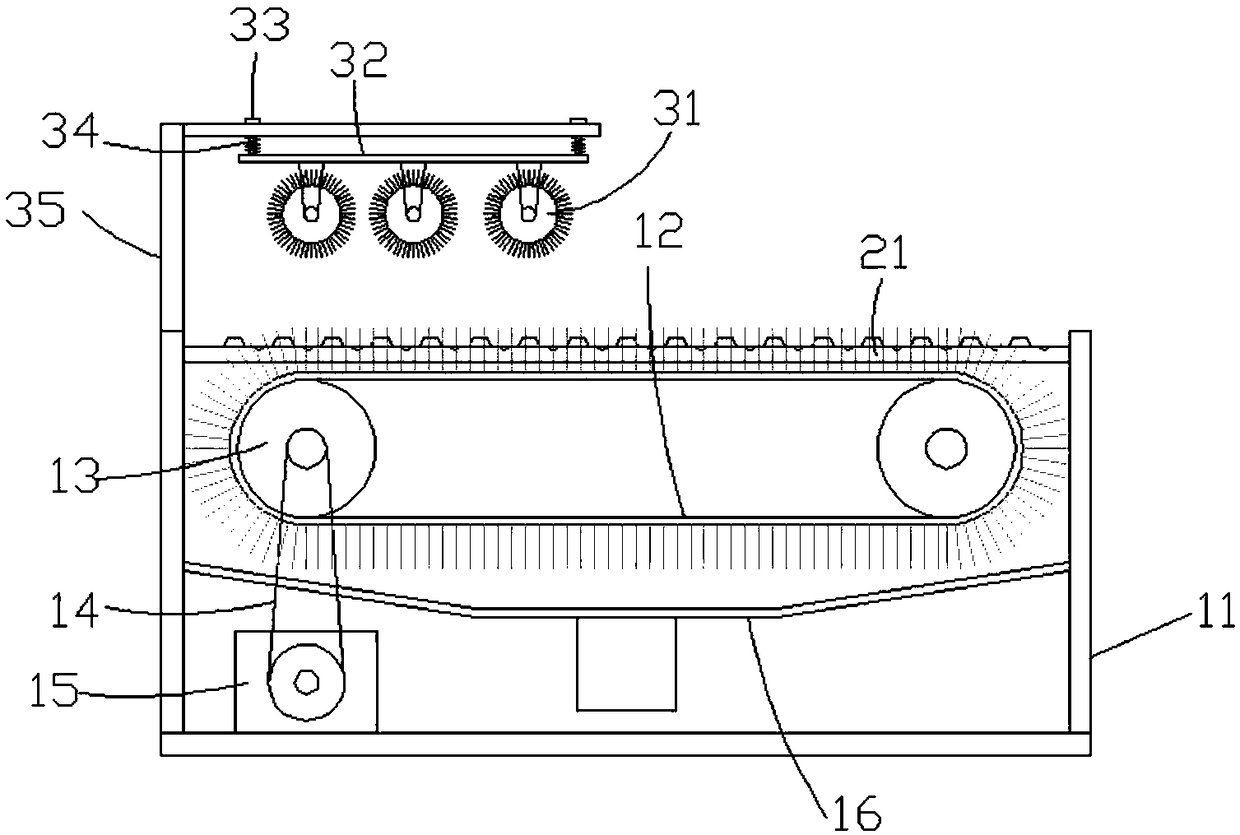

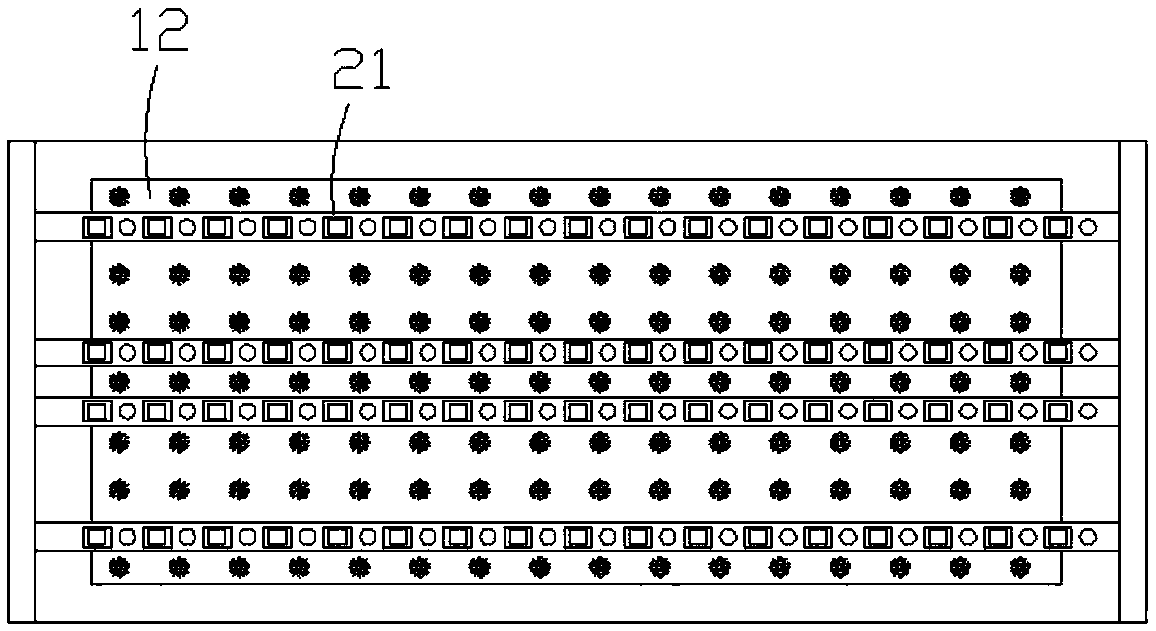

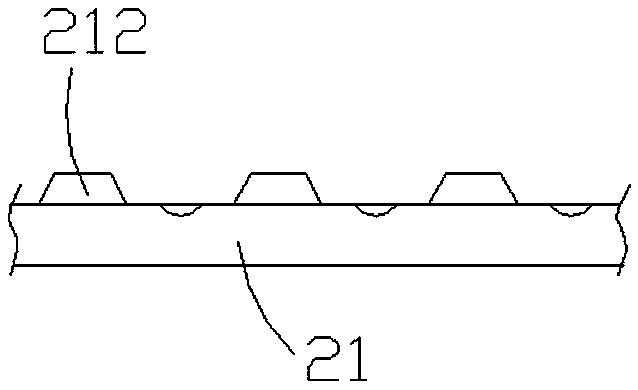

[0016] Such as Figure 1 to Figure 3 , a shoe cleaning mechanism of the present invention, comprising a box body 11, a belt brush 12, a driving pulley 13, a driving belt 14, a cleaning motor 15, a partition 16, a support pipe 21, an air pump, a cleaning brush wheel 31, and a mounting plate 32 , guide rod 33, spring 34, mounting bracket 35 and drive motor, partition plate 16 is fixed in the casing 11, and partition plate 16 divides the inner cavity of casing 11 into an upper cavity and a lower cavity. Two driving pulleys 13 are connected in rotation in the upper chamber, belt brush 12 is wound on the two driving pulleys 13, cleaning motor 15 is fixed outside the casing 11, and cleaning motor 15 is connected with one of the driving pulleys through driving belt 14 13 linkages. A plurality of support tubes 21 are fixed in the upper chamber parallel to each other, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com