Separable filter screen of water inlet valve

A water inlet valve and separate technology, which is applied in the field of washing machine water inlet valve separate filter screen structure, can solve the problems of cumbersome disassembly and cleaning process of the filter screen, poor water quality of users, foreign objects entering, etc., and achieve reasonable and humanized design, Improve the filtering effect and eliminate the effect of potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

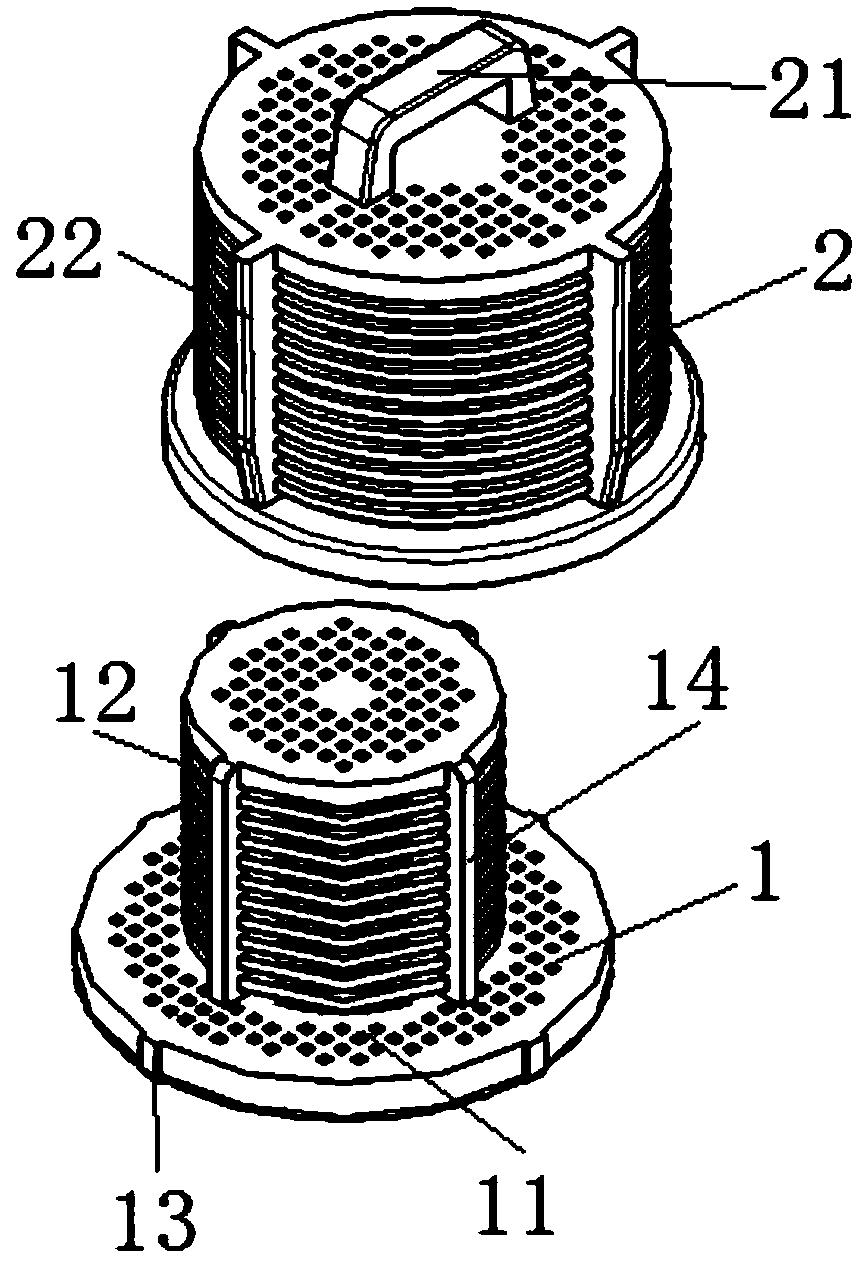

[0020] This inlet valve separation type filter screen of the present invention, as figure 1 As shown, it includes a first filter screen 1 fixedly connected to the port of the water inlet valve, and a detachable second filter screen 2 is sheathed on the first filter screen 2 . In the present invention, the original iron filter screen on the water inlet valve is changed into a separate plastic double filter screen, the first filter screen 1 and the second filter screen 2; The first filter screen 1 is fixedly connected, and the external second filter screen 2 can be easily disassembled for easy disassembly and cleaning. And the dual filter design can relatively improve the filtering effect.

[0021] In the present invention, if figure 1 As shown in , the first filter screen 1 includes a filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com