Adjustable fixture based on blade root inclined surface positioning

A fixture and bevel technology, applied in the field of debuggable fixtures, can solve the problems of low positioning accuracy, shorten the calibration fixture time, poor versatility, etc., and achieve the effects of ensuring stability and accuracy, improving service life, and improving general performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

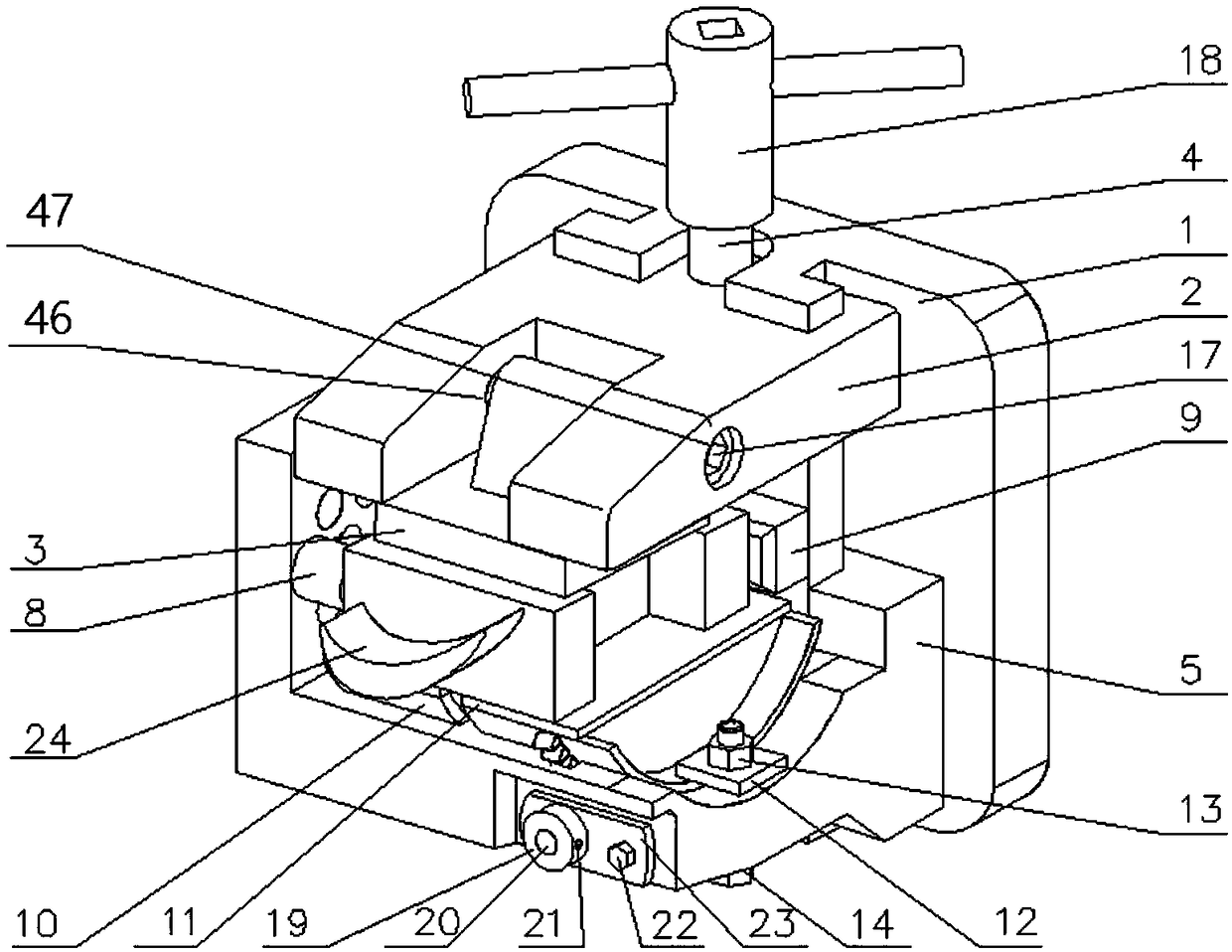

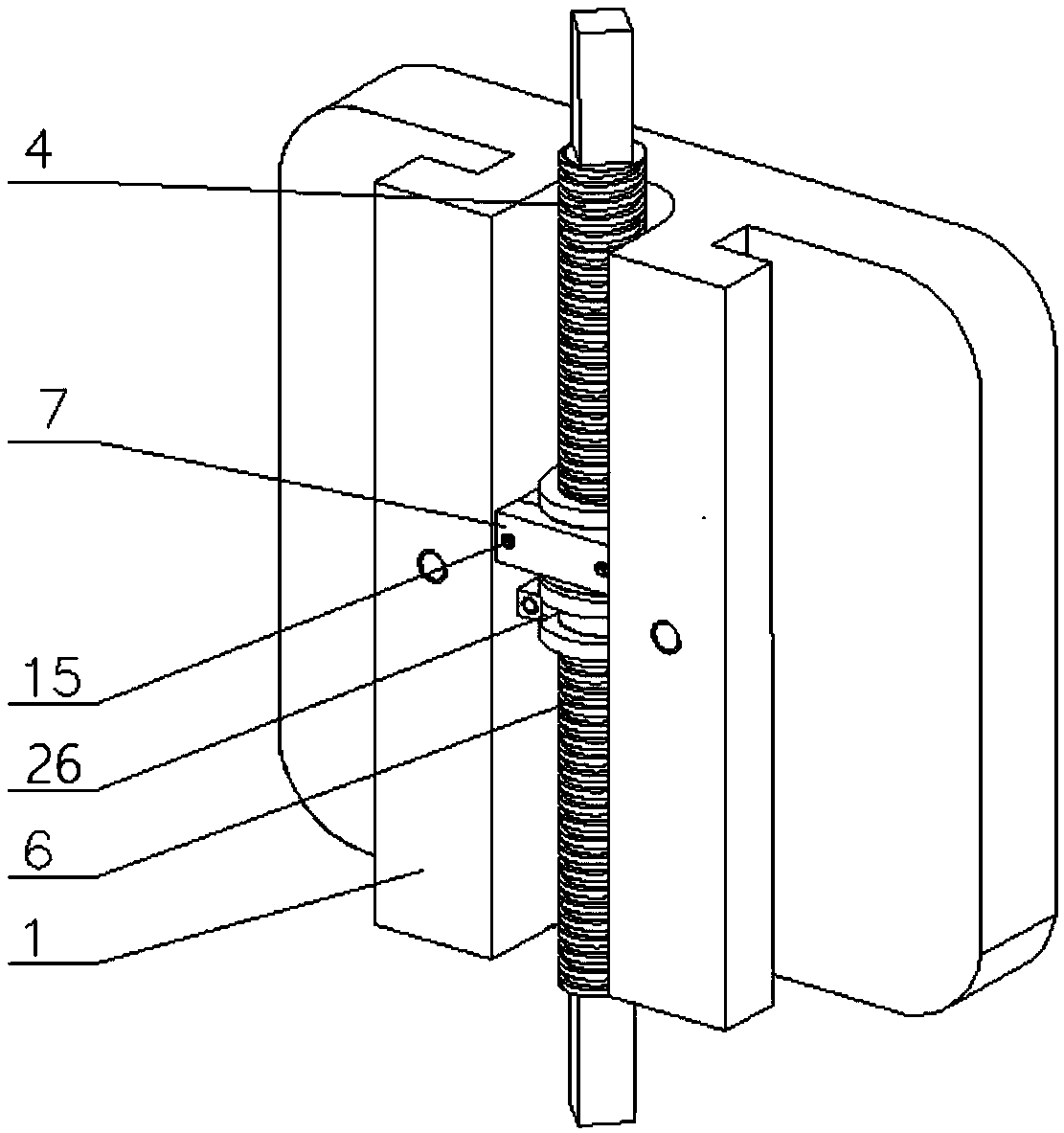

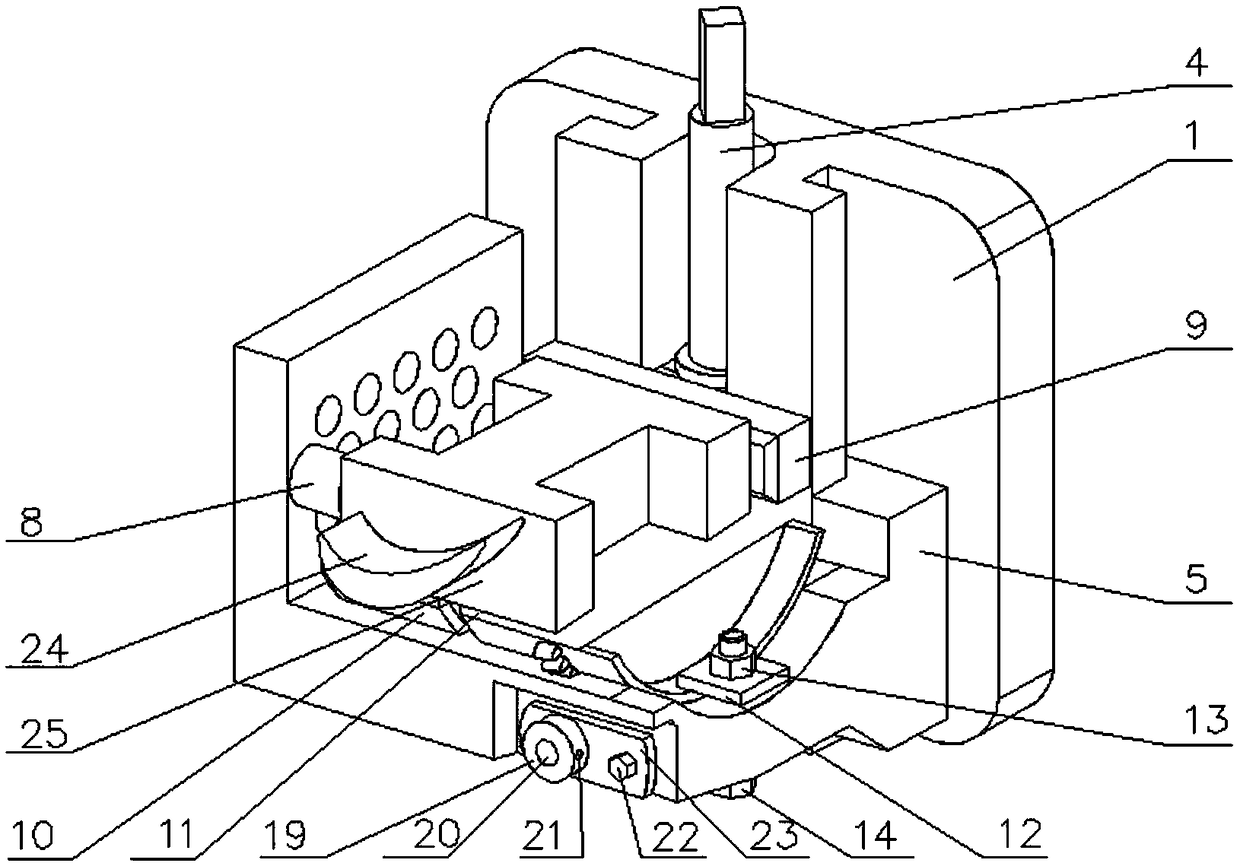

[0035] An adjustable fixture based on blade root slope positioning, including clamp body 1, movable upper cover 2, clamping plate 3, upper cover screw 4, movable positioning platform 5, positioning platform screw 6, screw fixing plate 7, and positioning support nails 8. Positioning support plate 9, angle adjustment block 10, positioning plane plate 11, pressure plate 12, compression nut 13, compression bolt 14, fixing screw 15, countersunk screw 16, clamping plate shaft 17, screw handle 18, angle Adjustment handle 19, angle adjustment rod 20, self-locking screw 21, hexagon bolt 22, fixed sleeve 23. The clamp body 1 is connected to the main shaft of the machine tool.

[0036]The upper cover screw 4 and the positioning table screw 6 are respectively installed in the upper and lower screw installation cavities of the clamp body 1 through two screw fixing plates 7 . The positioning table screw rod 6 is threadedly connected with the movable positioning table 5, and the movable pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com