A kind of pultrusion production method and equipment of fiber-reinforced composite curved profile

A composite material and fiber-reinforced technology, which is applied in the field of fiber-reinforced composite material structure, can solve the problems of inaccurate control of fiber and resin content and high requirements for mold manufacturing, and achieve clear motion trajectory, easy control, and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

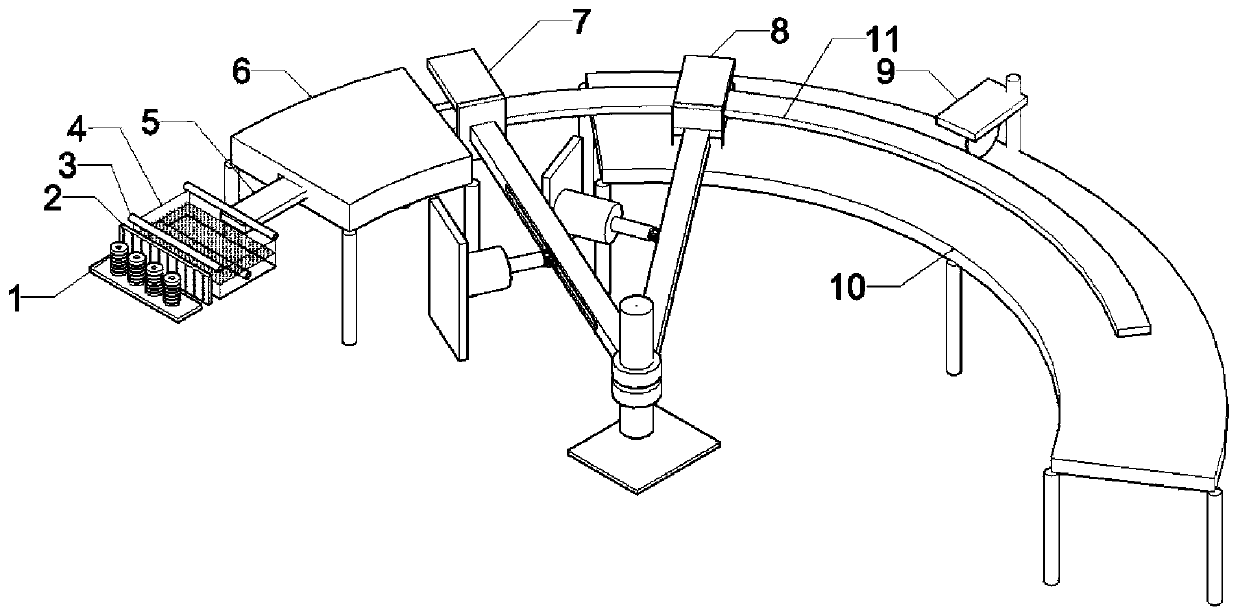

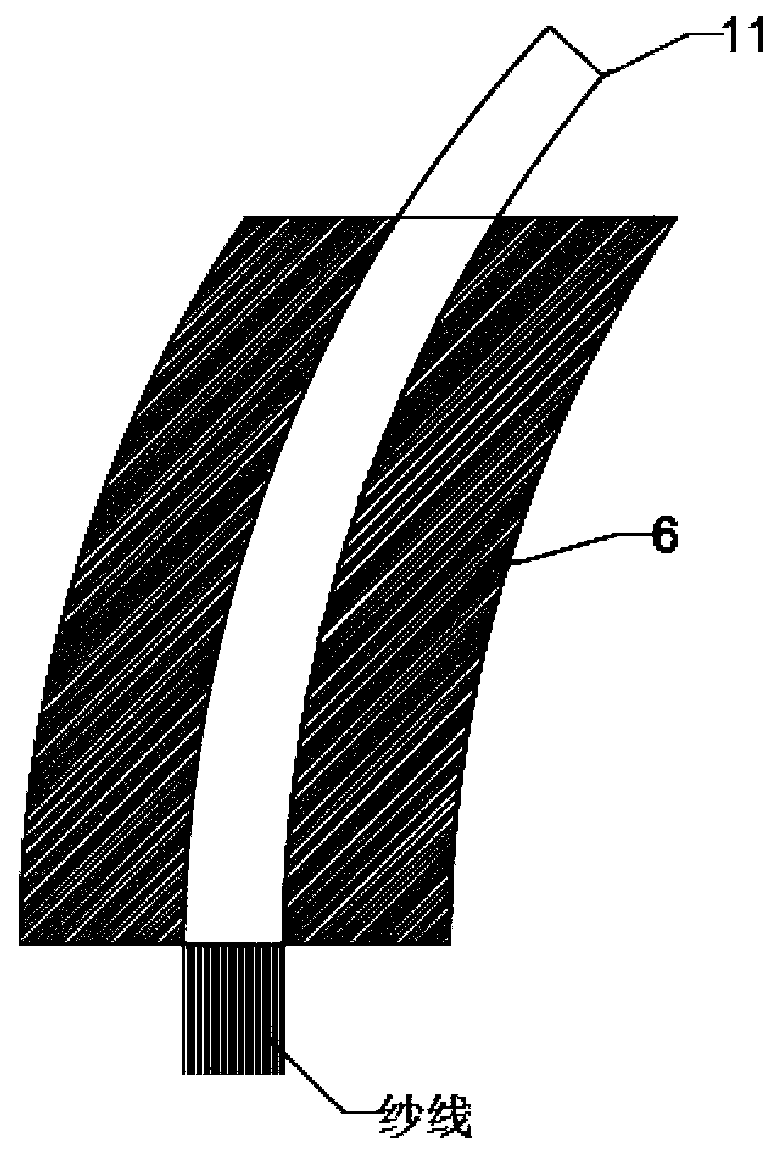

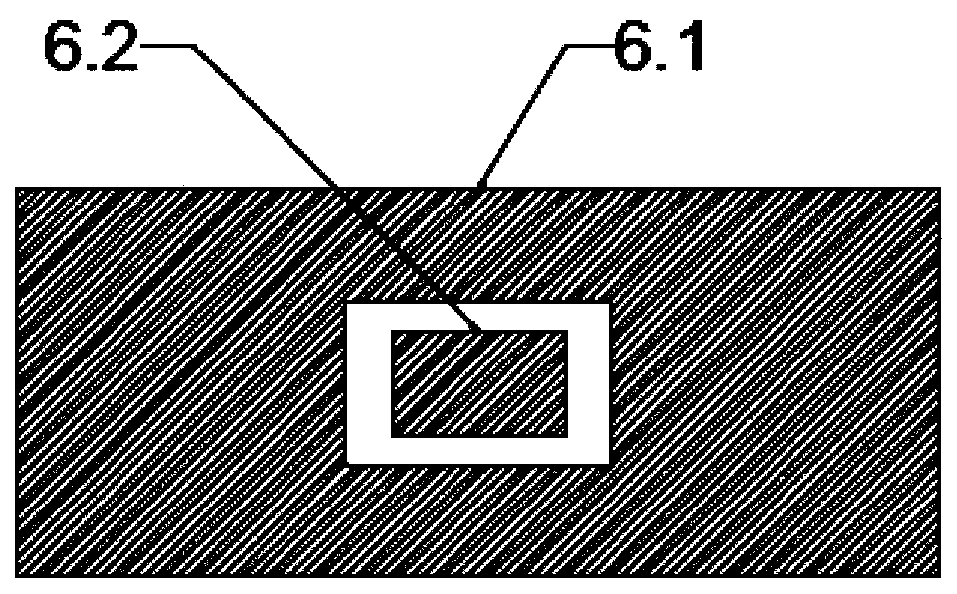

[0035] A kind of pultrusion production equipment (such as figure 1 shown), the equipment includes a creel 1, a fiber arrangement plate 2, a guide roller 3, a resin glue tank 4, a preforming mold 5, a curing mold 6, a pulling device, a cutting device 9 and a frame 10; the creel 1, The fiber arrangement plate 2 and the resin glue groove 4 are arranged in sequence at the front end of the preforming mold 5, the outlet of the resin glue groove 4 is connected with the inlet end of the preforming mold 5, and the guide roller 3 is placed in the pool of the resin glue groove 4 The middle position between the front and rear ends of the top and the bottom of the pool; the outlet end of the preforming mold 5 communicates with the inlet end of the curing mold 6, and a traction device is arranged outside the outlet end of the curing mold 6, and a cutting device 9 is arranged behind the traction device. The mold 6 and the cutting device 9 are fixed on the frame 10 .

[0036] Described tract...

Embodiment 2

[0041] A kind of pultrusion production equipment (such as figure 1 shown), the equipment includes a creel 1, a fiber arrangement plate 2, a guide roller 3, a resin glue tank 4, a preforming mold 5, a curing mold 6, a pulling device, a cutting device 9 and a frame 10; the creel 1, The fiber arrangement plate 2 and the resin glue groove 4 are arranged in sequence at the front end of the preforming mold 5, the outlet of the resin glue groove 4 is connected with the inlet end of the preforming mold 5, and the guide roller 3 is placed in the pool of the resin glue groove 4 The middle position between the front and rear ends of the top and the bottom of the pool; the outlet end of the preforming mold 5 communicates with the inlet end of the curing mold 6, and a traction device is arranged outside the outlet end of the curing mold 6, and a cutting device 9 is arranged behind the traction device. The mold 6 and the cutting device 9 are fixed on the frame 10 .

[0042] Described tract...

Embodiment 3

[0047] A kind of pultrusion production equipment (such as figure 1 shown), the equipment includes a creel 1, a fiber arrangement plate 2, a guide roller 3, a resin glue tank 4, a preforming mold 5, a curing mold 6, a pulling device, a cutting device 9 and a frame 10; the creel 1, The fiber arrangement plate 2 and the resin glue groove 4 are arranged in sequence at the front end of the preforming mold 5, the outlet of the resin glue groove 4 is connected with the inlet end of the preforming mold 5, and the guide roller 3 is placed in the pool of the resin glue groove 4 The middle position between the front and rear ends of the top and the bottom of the pool; the outlet end of the preforming mold 5 communicates with the inlet end of the curing mold 6, and a traction device is arranged outside the outlet end of the curing mold 6, and a cutting device 9 is arranged behind the traction device. The mold 6 and the cutting device 9 are fixed on the frame 10 .

[0048] Described tract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com