Bio-enzyme-CTAB joint conditioning method for sludge

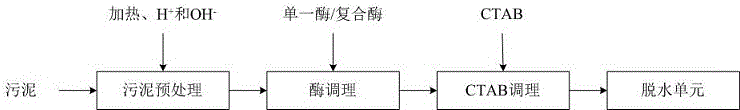

A-CTAB, biological enzyme technology, applied in the field of enzyme and surfactant combined to promote sludge dewatering performance, biological preparations and chemical substances to adjust sludge to reduce the amount of sludge, can solve the problem that the sludge dewatering effect is not significant and cannot be Destroy the EPS structure of sludge and other problems, and achieve the effects of mild applicable conditions, clear conditioning steps, and improved solid-liquid separation ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Combined Conditioning with Compound Enzyme-CTAB Improves Dewatering Performance of Activated Sludge

[0032] The medium temperature a-amylase solution is prepared as follows: dissolve 2.85g amylase in 50mL, pH=6.2 phosphate buffer, and then add 25mg anhydrous CaCl 2 The powder, as an activator of amylase, was dissolved by heating and stirring at 40°C, and then centrifuged at 1000 rpm, and the supernatant was taken as a medium-temperature α-amylase solution, which was prepared and used.

[0033] The neutral protease solution is prepared as follows: dissolve 3 g of neutral protease in 50 mL of phosphate buffer with pH of 7.2, heat and stir at 40°C to dissolve, and then centrifuge at 1000 rpm. The supernatant is taken as the protease solution. Available now.

[0034] Compound enzyme-CTAB joint conditioning: activated sludge from a municipal sewage treatment plant, after 4 hours of sedimentation, the supernatant was discarded, and the concentrated sludge passed ...

Embodiment 2

[0038] Example 2: Changes in dewatering performance after combined conditioning of digested sludge with mesophilic α-amylase and CTAB

[0039] Take 25 L of anaerobic digested sludge (water content of 96.27%) from a municipal sewage treatment plant, and adjust the temperature and pH of the anaerobic sludge to 45 °C and 6.2 with a heating device and 1 mol / L HCl solution, respectively. Add a certain amount of CaCl to the mud 2 solids that make the Ca in the sludge 2+ The concentration is 120mg·L -1 Then add 56g of medium-temperature α-amylase when the rotating speed is 250 rpm, after mixing for 2 minutes, adjust the rotating speed to 120 rpm, and shake at a constant temperature of 45 ° C for 2 hours. After the amylase conditioning is completed, the above sludge sample is transferred to the mixer In the equipment, when the rotating speed is 650rpm, add 180g of CTAB, after stirring for 3min, under the condition of rotating speed of 50rpm, slowly stir for 10min, then directly carr...

Embodiment 3

[0040] Example 3: Dewatering performance of neutral protease-CTAB combined conditioning of excess sludge

[0041] After passing through a 0.18cm mesh screen, 300mL of the excess sludge (water content of 98.6%) from a municipal sewage treatment plant was taken out and placed in a 500mL conical flask, and its temperature and pH were adjusted to 37.6°C and 7.23, respectively. Add 7mL of protease solution at 200rpm, mix for 2min, shake at 50rpm for 3h, after neutral protease treatment, move the sludge sample into a six-joint mixer, add 1.26g of CTAB and stir quickly for 10min at 720rpm After that, the mixture was stirred at a slow speed of 62 rpm for 10 min, and then vacuum filtered. The pressure and time parameters were 0.06 MPa and 20 min, respectively. The moisture content of the mud cake after suction filtration was determined to be 69.64%, and the moisture content of the mud cake of the original sludge was 75.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com