A kind of high hardness composite material

A composite material, high hardness technology, applied in the field of composite materials, can solve the problems of easy falling off of coating, easy broken glass, uneven particle distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

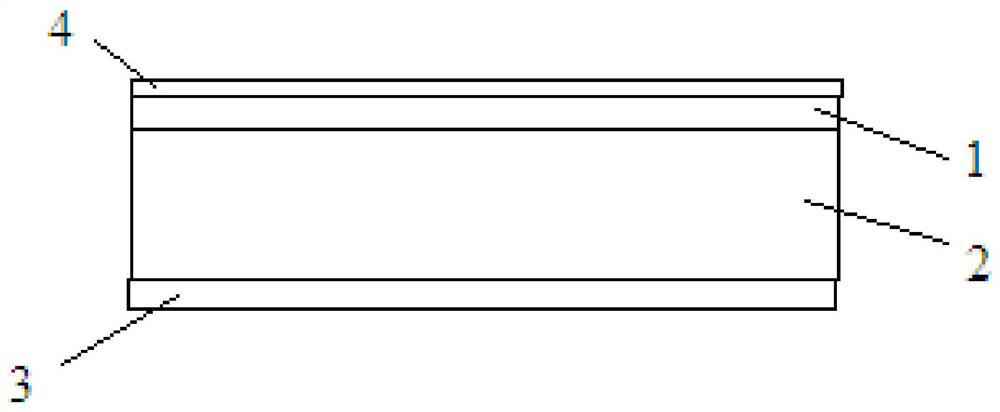

[0029] Such as figure 1 As shown, the high-hardness composite material provided in this embodiment, from top to bottom, the composite material sequentially includes a first polycarbonate layer 1, a polymethyl methacrylate layer 2 and a second polycarbonate layer 3, the first polycarbonate layer The upper surface of the carbonate layer 1 is printed with a nano transparent film 4;

[0030] The preparation method of composite material at least includes the following steps:

[0031] In the first step, in the multi-slit coating equipment, the molten first polycarbonate, the molten polymethyl methacrylate and the molten second polycarbonate are simultaneously injected from three adjacent slits. Shot into the cooling roll, so that the three molten layers are solidified and formed at one time to obtain the main material;

[0032] In the second step, the nano-transparent film is printed on one of the surfaces of the main material by a roller.

[0033] Wherein, the thickness ratio of...

Embodiment 2

[0038] Such as figure 1 As shown, the high-hardness composite material provided in this embodiment, from top to bottom, the composite material sequentially includes a first polycarbonate layer 1, a polymethyl methacrylate layer 2 and a second polycarbonate layer 3, the first polycarbonate layer The upper surface of the carbonate layer 1 is printed with a nano transparent film 4;

[0039] The preparation method of composite material at least includes the following steps:

[0040] In the first step, in the multi-slit coating equipment, the molten first polycarbonate, the molten polymethyl methacrylate and the molten second polycarbonate are simultaneously injected from three adjacent slits. Shot into the cooling roll, so that the three molten layers are solidified and formed at one time to obtain the main material;

[0041] In the second step, the nano-transparent film 4 is printed on one of the surfaces of the main material by a roller.

[0042] Wherein, the thickness ratio ...

Embodiment 3

[0047] Such as figure 1 As shown, the high-hardness composite material provided in this embodiment, from top to bottom, the composite material sequentially includes a first polycarbonate layer 1, a polymethyl methacrylate layer 2 and a second polycarbonate layer 3, the first polycarbonate layer The upper surface of the carbonate layer 1 is printed with a nano transparent film 4;

[0048] The preparation method of composite material at least includes the following steps:

[0049] In the first step, in the multi-slit coating equipment, the molten first polycarbonate, the molten polymethyl methacrylate and the molten second polycarbonate are simultaneously injected from three adjacent slits. Shot into the cooling roll, so that the three molten layers are solidified and formed at one time to obtain the main material;

[0050] In the second step, the nano-transparent film 4 is printed on one of the surfaces of the main material by a roller.

[0051] Wherein, the thickness ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com