Liquid medicine dispersing device in flexible plate-making machine

A technology of dispersing device and plate making machine, which is applied in the field of machinery, can solve the problems affecting the yield of flexographic printing plates, etc., and achieve the effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

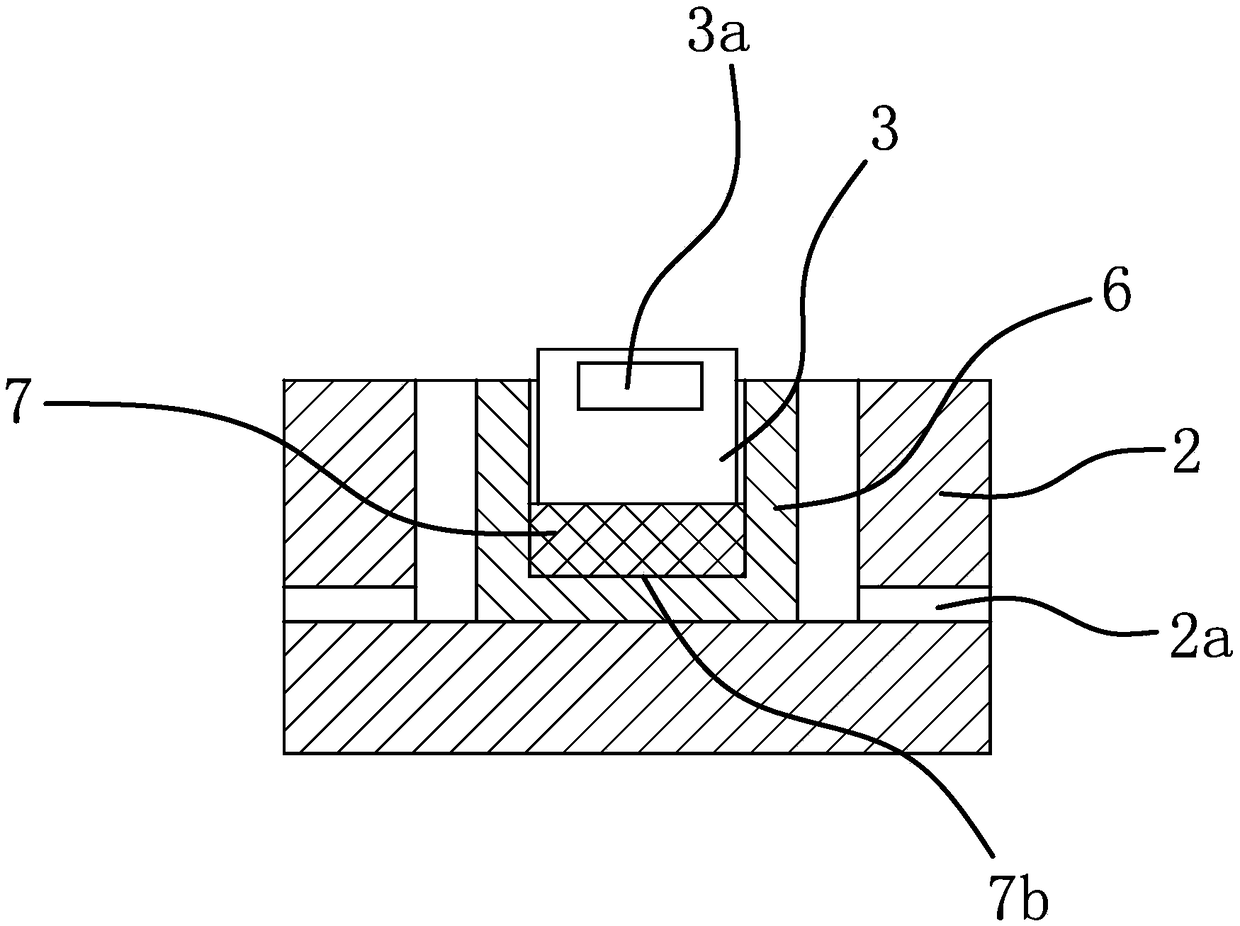

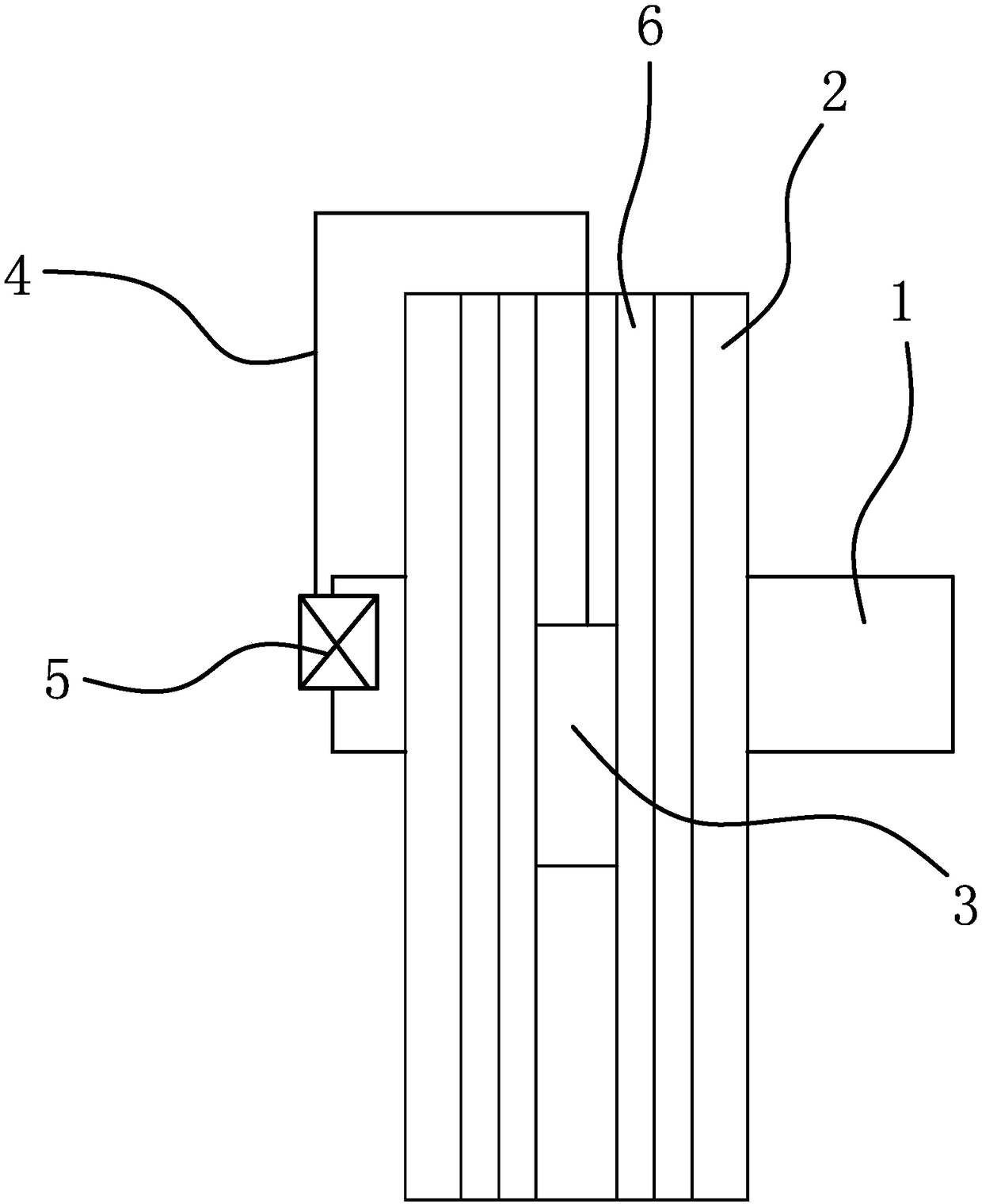

[0032] Such as figure 1 As shown, the flexographic platemaking machine includes a frame 1 .

[0033] Such as figure 1 and figure 2 As shown, the liquid medicine dispersing device in the flexible plate-making machine includes a water tank 2, a water storage box 3, a connecting pipe 4 and a water pump 5. The water tank 2 is long and has a concave water outlet channel along its length direction. The water pump 5 is solid Connected to the frame 1 and the water pump 5 is connected in series to the connecting pipe 4, the outer end of the connecting pipe 4 is used to connect with the liquid medicine pool, the inner end of the connecting pipe 4 communicates with the water storage box 3, and the middle part of the above-mentioned water tank 2 is connected to the water storage box 3 They are connected by a connection structure, and the side of the above-mentioned water tank 2 has several through-holes 2a.

[0034] It also includes a transition groove 6, the two ends of the transitio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap