Industrial atmospheric-pressure storage tank

A storage tank and industrial technology, which is applied in the field of industrial atmospheric storage tanks, can solve problems such as tank lids flying off, increased maintenance risks, and pressure changes in storage tanks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

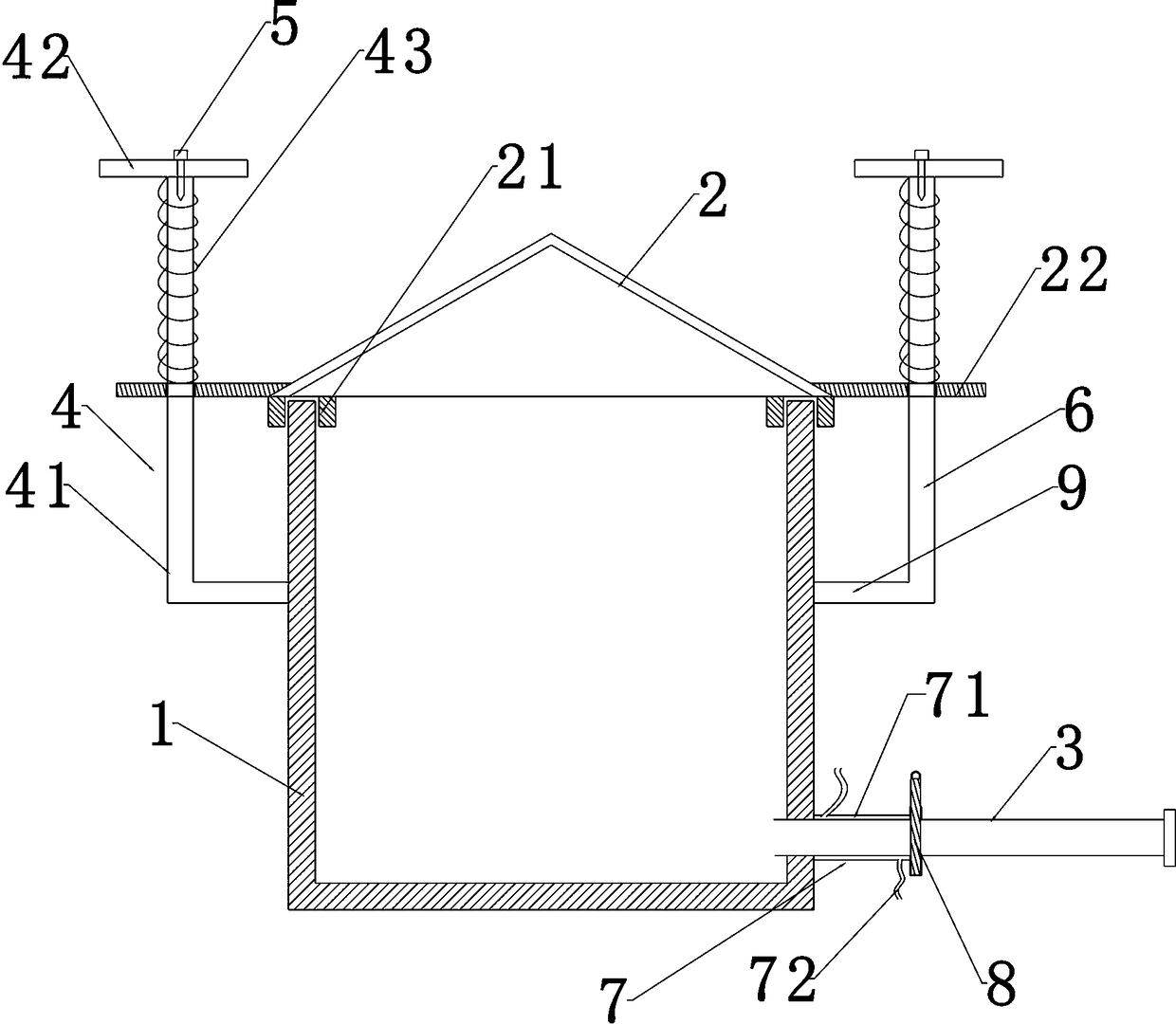

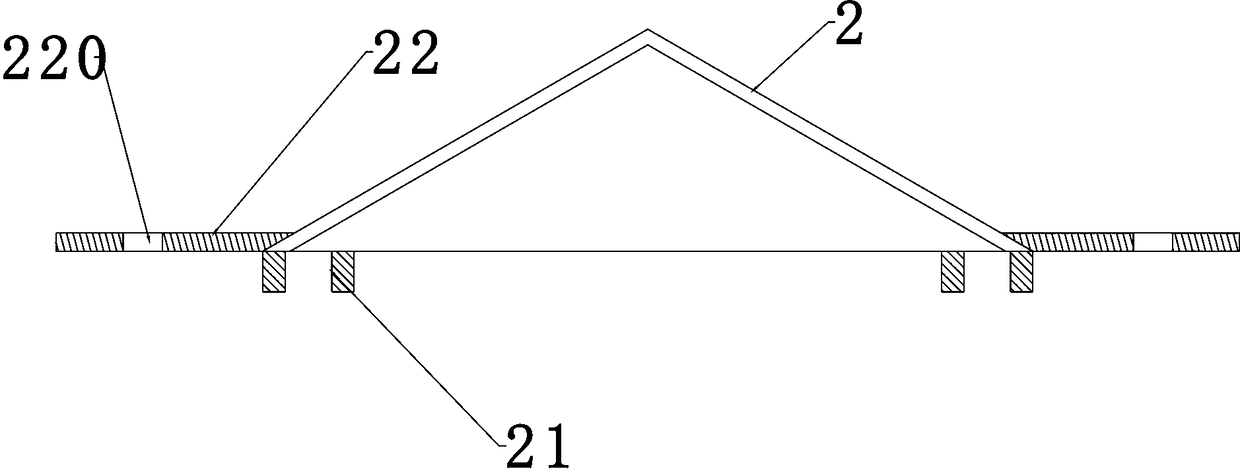

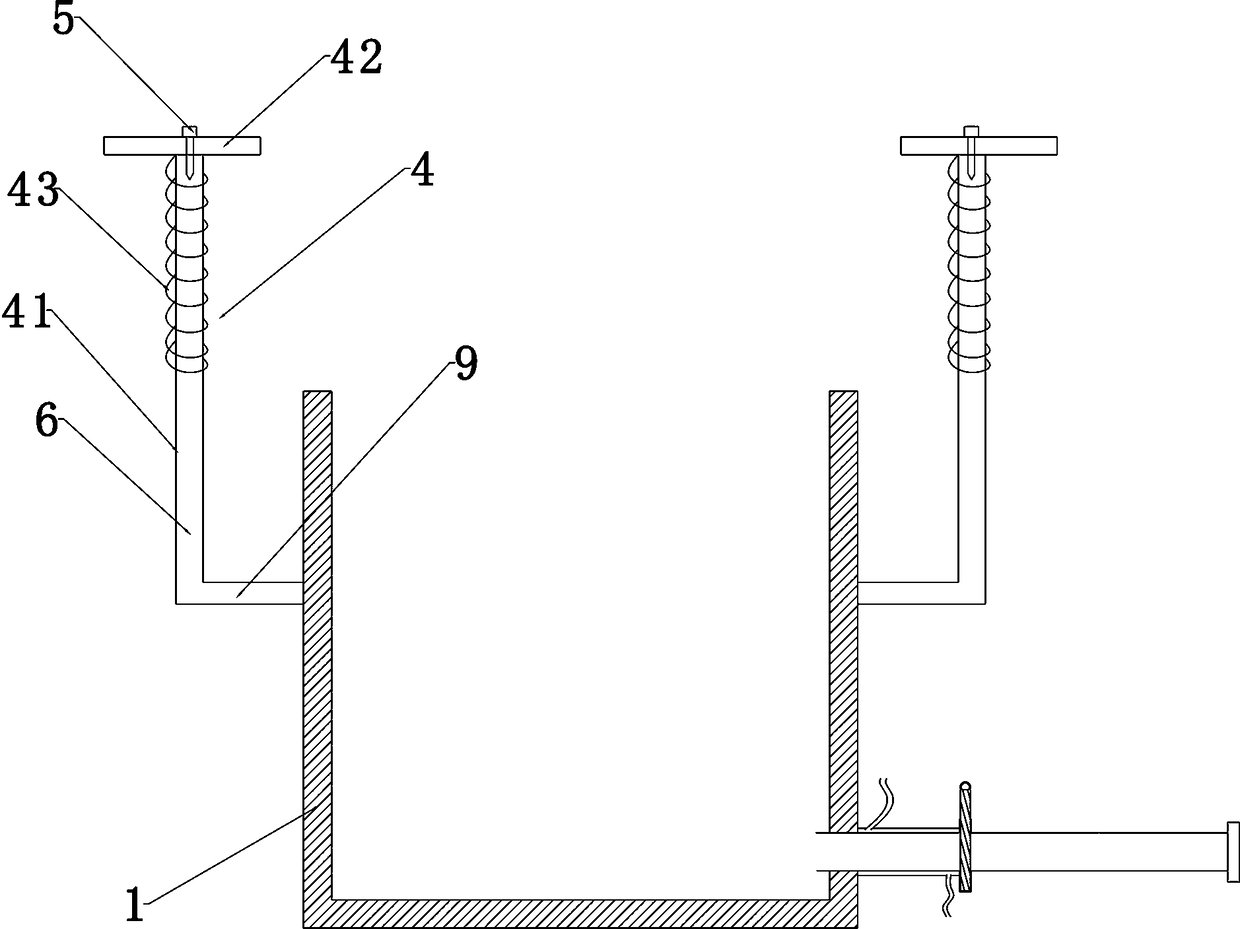

[0018] Such as Figure 1-3 As shown, the present invention discloses an industrial atmospheric storage tank, which includes a tank body 1 and a tank cover 2, the bottom of the tank body 1 is provided with an output port for outputting industrial raw materials, and the output port is connected to the external output The pipe 3 is connected; the circumference of the tank cover 2 is provided with a circular card slot 21 which is fastened with the upper opening of the tank body; Both sides are provided with anti-bullet opening device 4, and described anti-bullet opening device 4 comprises guide column 41, baffle plate 42 and return spring 43; 22 is passed through the guide column 41, and is buckled on the upper end of the tank body 1; the b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap