Fuel oil aid, preparation method thereof and application of fuel oil aid

A technology of fuel oil and additives, applied in the direction of fuel additives, fuel, petroleum industry, etc., can solve the problems of affecting the service life of the engine, low fuel combustion efficiency, and inability to achieve the effect, so as to protect the engine, improve the oil quality, reduce the The effect of maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

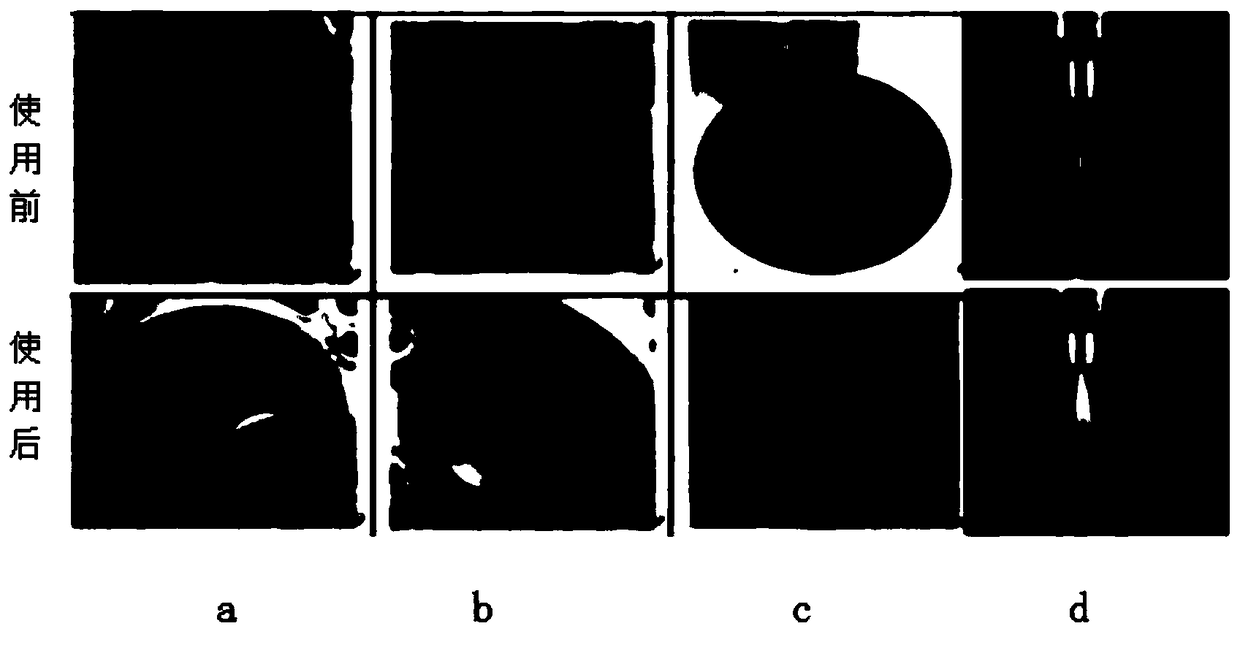

Image

Examples

Embodiment 1

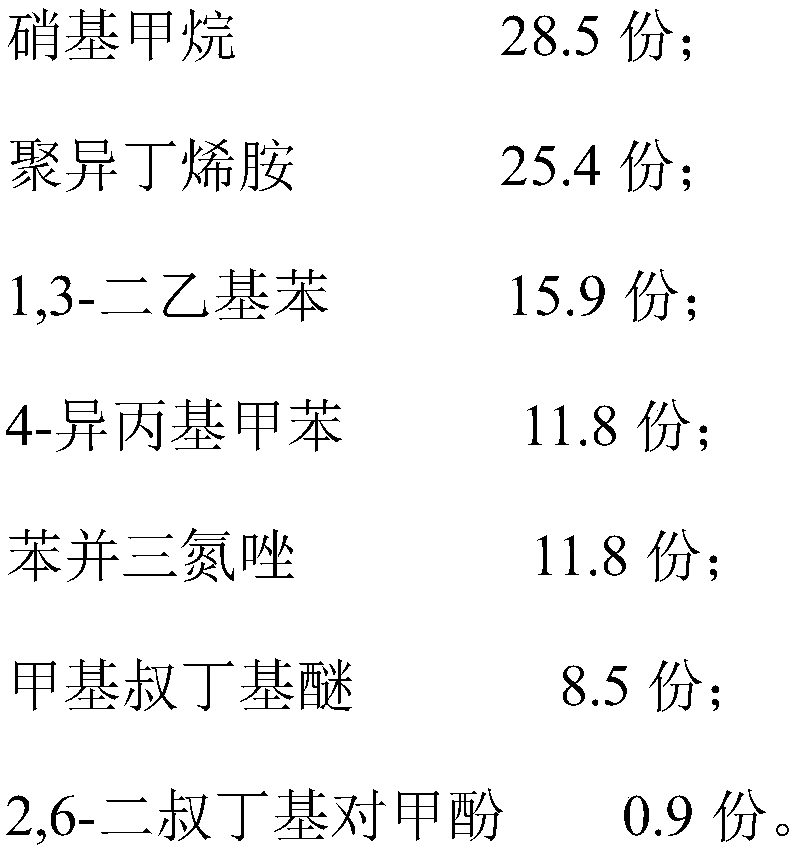

[0018] The following raw material components measured in parts by mass are weighed according to the proportion, and the fuel additive of the present invention is prepared by mixing and uniformly stirring at a temperature range from room temperature to not higher than 60°C by using nanotechnology.

[0019]

Embodiment 2

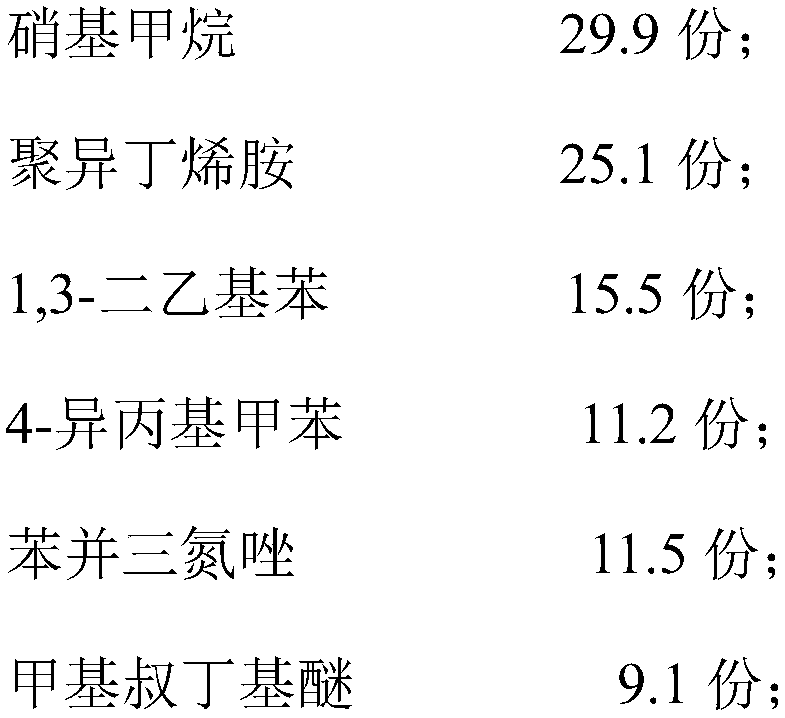

[0021] The following raw material components measured in parts by mass are weighed according to the proportion, and the fuel additive of the present invention is prepared by mixing and uniformly stirring at a temperature range from room temperature to not higher than 60°C by using nanotechnology.

[0022]

[0023]

Embodiment 3

[0025] The following raw material components measured in parts by mass are weighed according to the proportion, and the fuel additive of the present invention is prepared by mixing and uniformly stirring at a temperature range from room temperature to not higher than 60°C by using nanotechnology.

[0026]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap