Non-heat treatment strengthened high-strength high-toughness pressure casting aluminum-magnesium-silicon alloy and preparing method thereof

A magnesium-silicon alloy, high-strength and high-toughness technology, applied in the field of non-heat treatment strengthened high-strength and high-toughness die-casting aluminum-magnesium-silicon alloy and its preparation, can solve problems such as difficult to find materials, and achieve the effect of meeting application requirements and good die-casting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

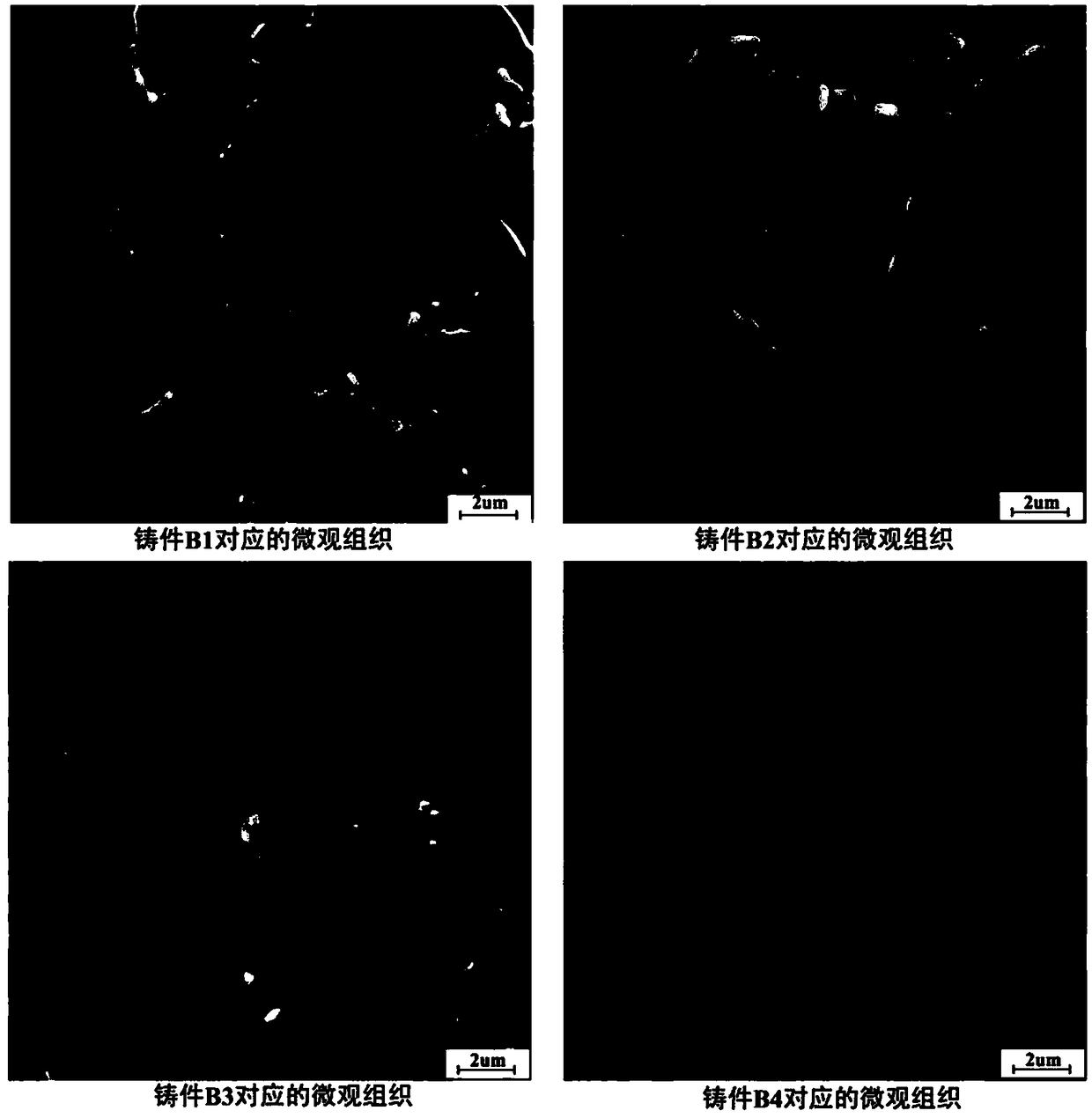

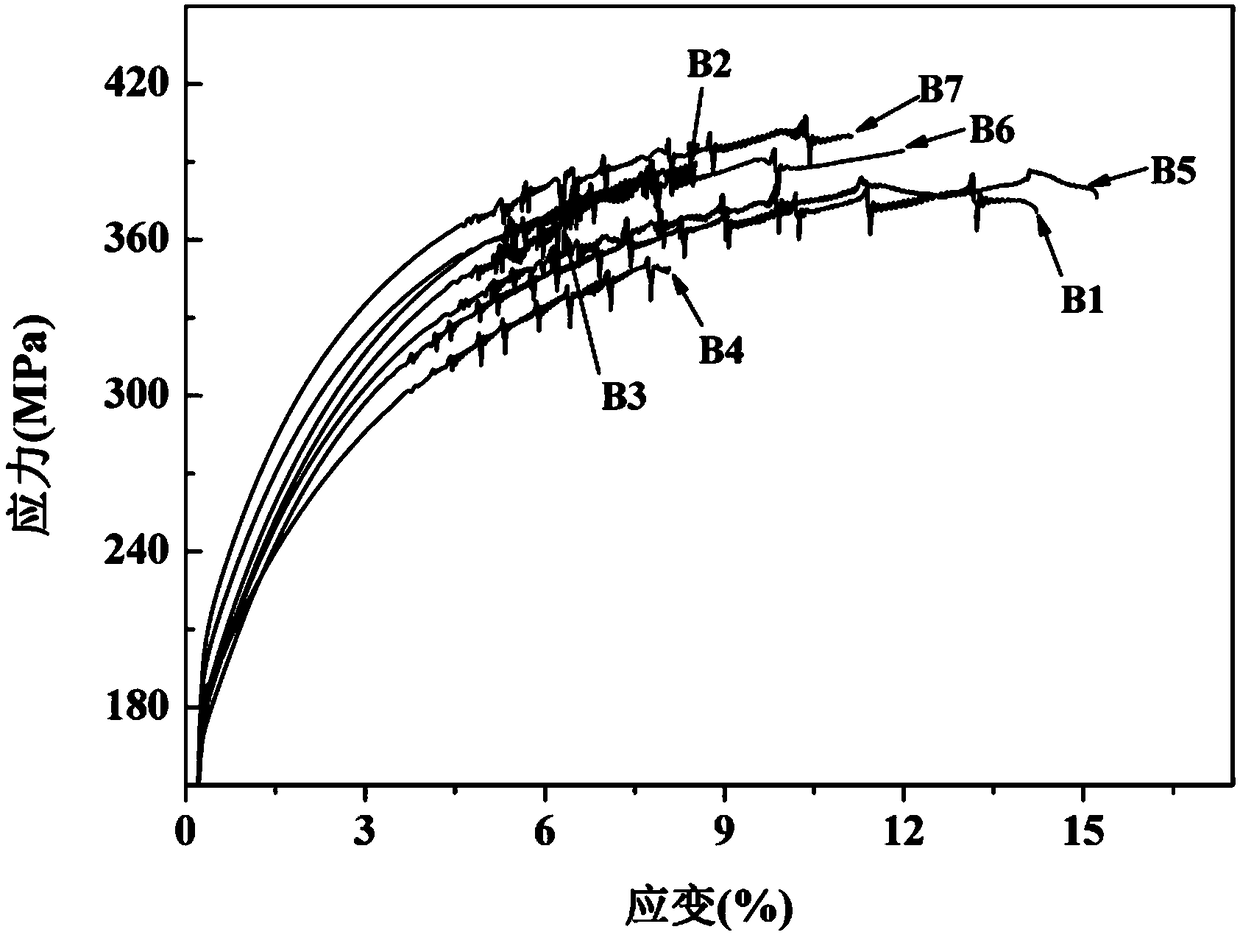

Embodiment 1

[0029] The weight percent of each component of a non-heat-treated high-strength and tough die-casting aluminum-magnesium-silicon alloy in this embodiment is: Mg: 6.5wt.%; Si: 2.2wt.%; Mn: 0.7wt.%; Ti: 0.15wt.% ; V: 0.04wt.%%; Zr: 0.03wt.%; Be: 0.005wt.%; Ca: 0.005wt.%; The balance is Al.

[0030] The preparation of a non-heat-treated high-strength die-casting aluminum-magnesium-silicon alloy and its die-casting process in this embodiment include the following steps:

[0031] 1) Drying: Prepare raw materials such as pure aluminum, pure Mg, Al-20Si master alloy, Al-10Mn master alloy, Al-10Ti master alloy, Al-5V master alloy, Al-5Zr master alloy, Mg-20Ca master alloy Alloy, Al-10RE and Al-5Be master alloy are preheated to 200°C for drying treatment;

[0032]2) Melting: Use a crucible resistance furnace for melting, first preheat the resistance furnace to 200°C, and then evenly coat the inner wall of the crucible with paint; after drying, first melt the weighed pure aluminum, an...

Embodiment 2

[0053] The weight percent of each component of a non-heat treatment strengthened high-strength and tough die-casting aluminum-magnesium-silicon alloy in this embodiment is: Mg: 6.0wt.%; Si: 2.0wt.%; Mn: 0.6wt.%; Ti: 0.15wt.%. %; V: 0.03wt.%%; Zr: 0.02wt.%; Be: 0.004wt.%; Ca: 0.003wt.%; , the balance being Al.

[0054] The preparation and die-casting process of a non-heat-treated high-strength and toughness die-casting Al-Mg-silicon alloy in this example are the same as those in Example 1, and casting B5 is obtained.

Embodiment 3

[0056] The weight percent of each component of a non-heat treatment strengthened high-strength and tough die-casting aluminum-magnesium-silicon alloy in this embodiment is: Mg: 7.5wt.%; Si: 2.5wt.%; Mn: 0.7wt.%; Ti: 0.15wt.%. %; V: 0.04wt.%%; Zr: 0.03wt.%; Be: 0.005wt.%; Ca: 0.005wt.%; , the balance being Al.

[0057] The preparation and die-casting process of a non-heat-treated high-strength and tough die-casting aluminum-magnesium-silicon alloy in this example are the same as in Example 1, and casting B6 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com