Patents

Literature

32results about How to "Important industrial application value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

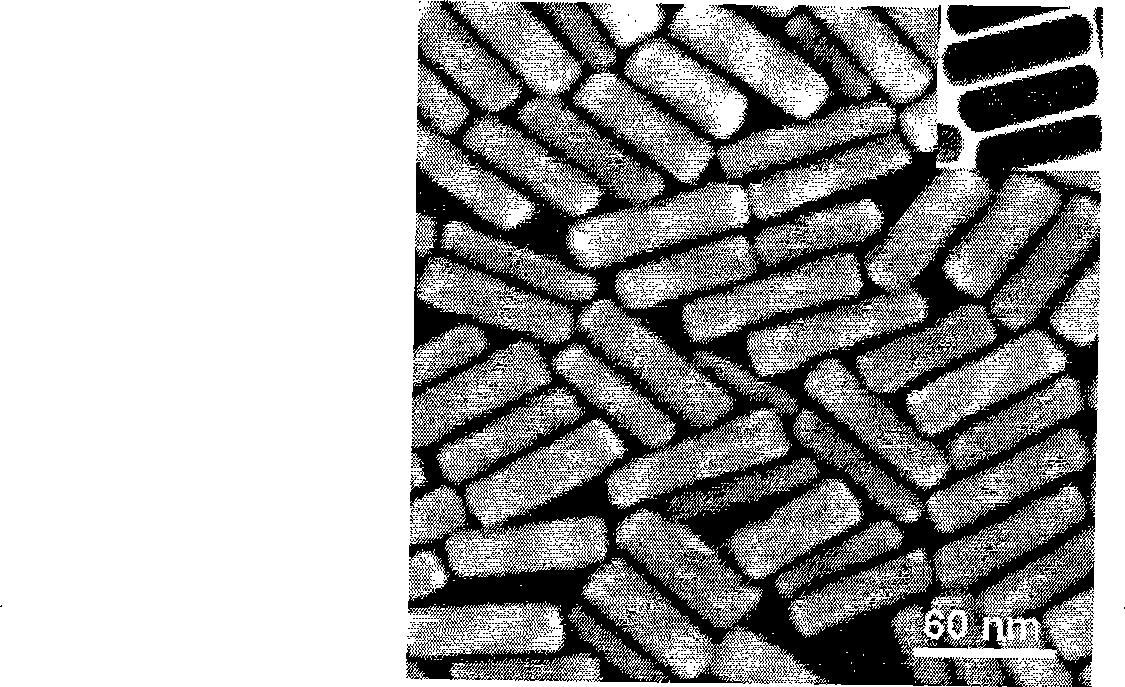

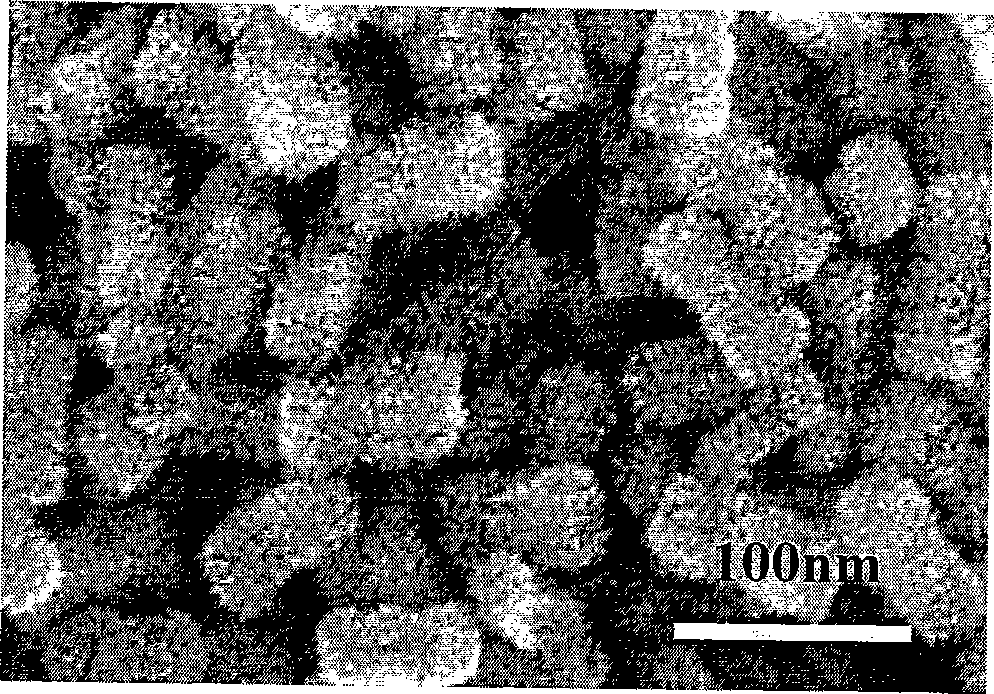

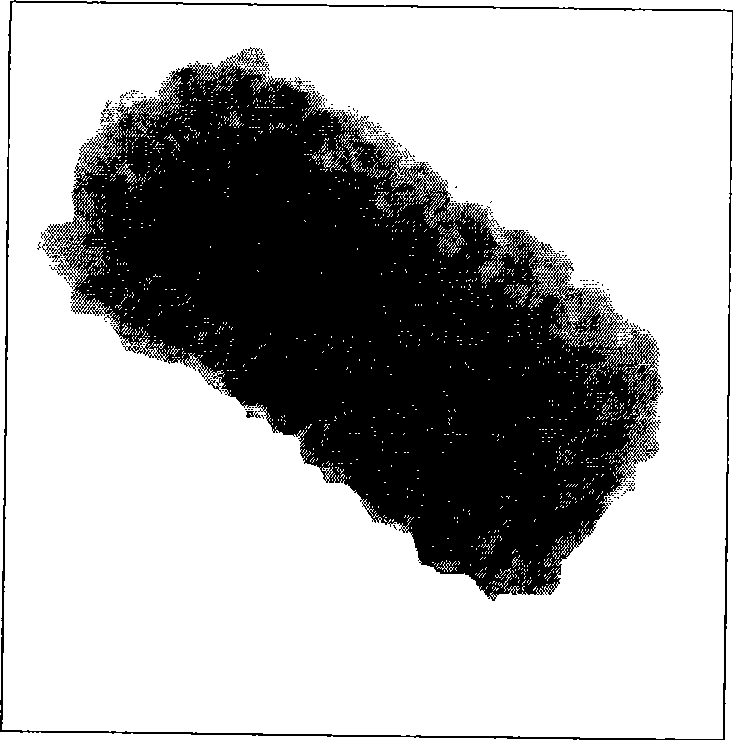

Bimetal nano rod of branched gold core/platinum shell structure and preparation method thereof

InactiveCN101450380AImprovement of poisoningLarge specific surface areaCoatingsPlatinumOptical property

The invention provides a dendritic gold-core / platinum-shell bimetal nanometer rod and a preparation method thereof. The dendritic gold-core / platinum-shell bimetal nanometer rod comprises a cylindrical gold nanometer-rod core and a porous platinum-shell layer covering the outer surface of the cylindrical gold nanometer-rod core; the diameter of the cylindrical gold nanometer-rod core is 10 to 15 nanometers; the length of the cylindrical gold nanometer-rod core is 55 to 60 nanometers; the thickness of the porous platinum-shell layer is 0.4 to 8 nanometers; and the length of platinum grains covering the outside of a nanometer rod is 2 to 4 nanometers. The preparation method provided by the invention has the advantages of simplicity, flexibility, environmental protection, green chemistry and low energy consumption. In addition, the obtained bimetal nanometer rod with a gold-core / platinum-shell structure has the characteristics of high yield, narrow size distribution, stable structure and adjustable optical properties.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

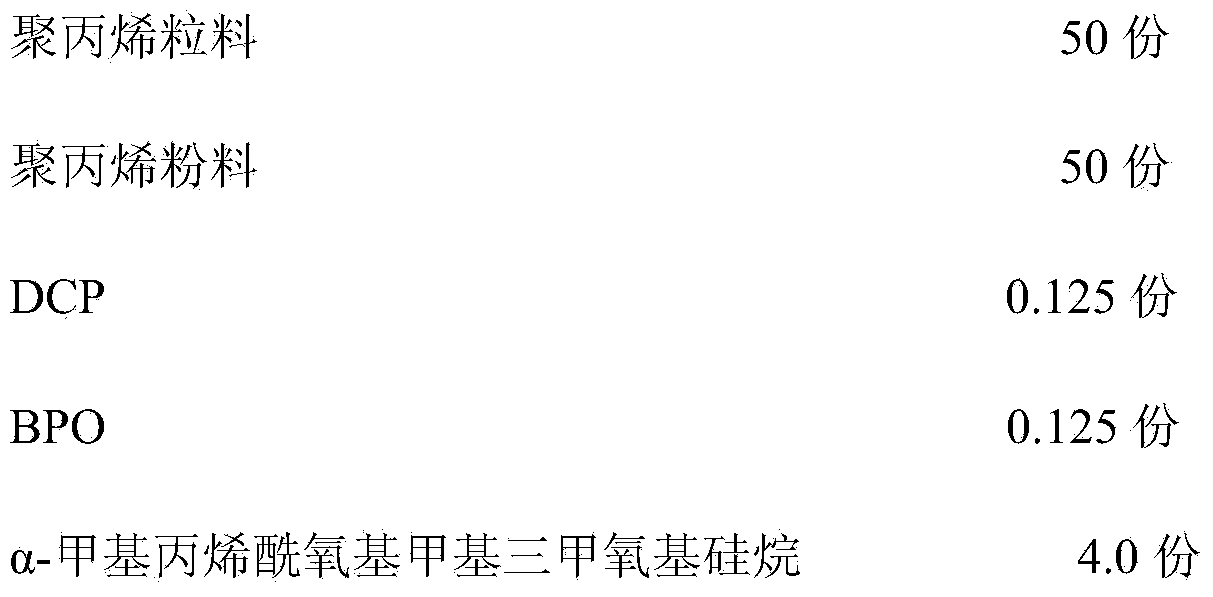

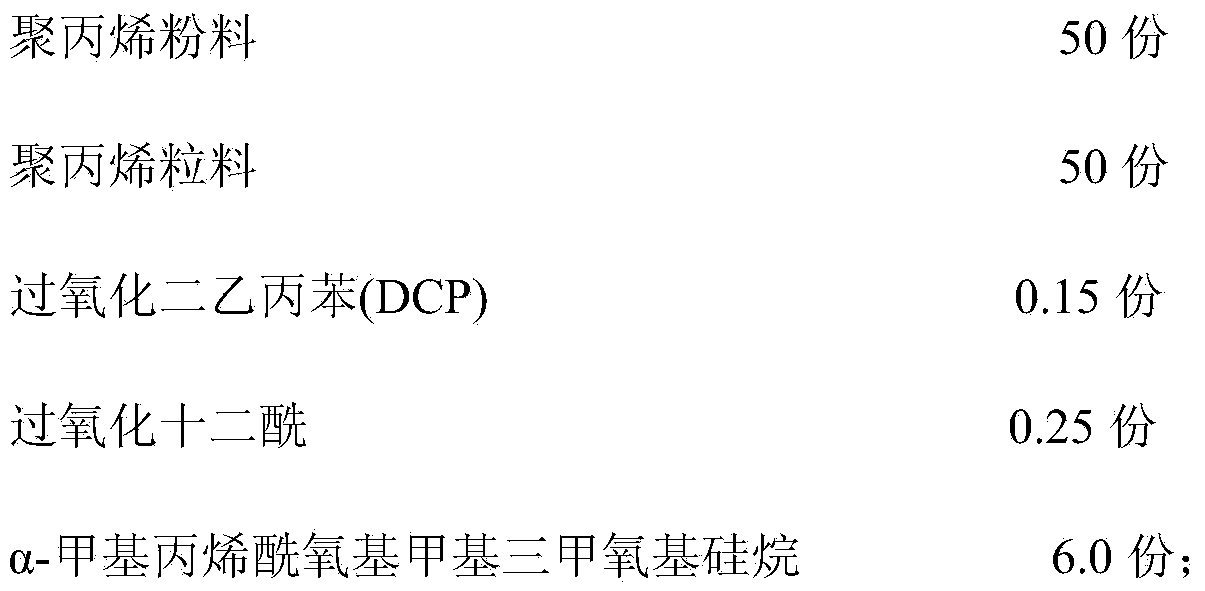

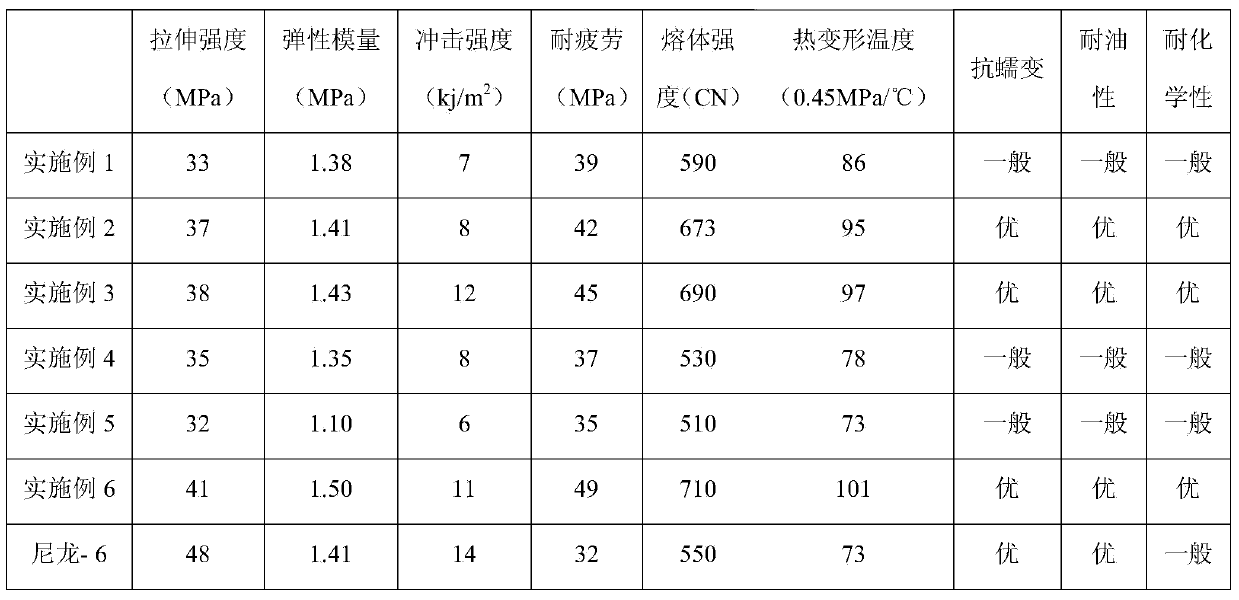

Alpha-silane cross-linked polypropylene and application thereof as 3D printing material

The invention discloses a cross-linked polypropylene, the cross-linked polypropylene is alpha-silane cross-linked polypropylene, and the cross-linked polypropylene is composed of the following raw materials in parts by weight: 100 parts of polypropylene, 0.10 to 0.50 part of peroxide, and 2.0 to 6.0 parts of alpha-silane. The alpha-silane cross-linked polypropylene is suitable for being used as a 3D printing material, a foaming material and a stretching-resistant braid material, and applied to other application fields, in which the material can replace nylon; compared to nylon, the material is lighter and more environment-friendly, furthermore, the cost of the material is lower, and thus the material has a very important industrial application value.

Owner:涌奇材料技术(上海)有限公司

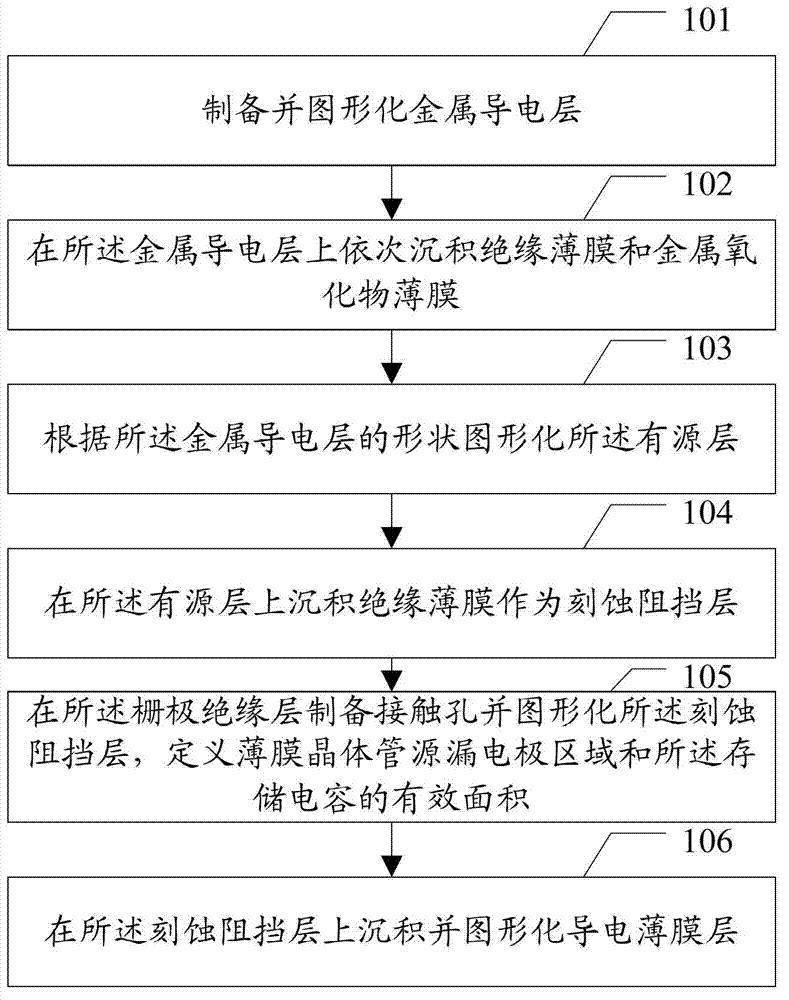

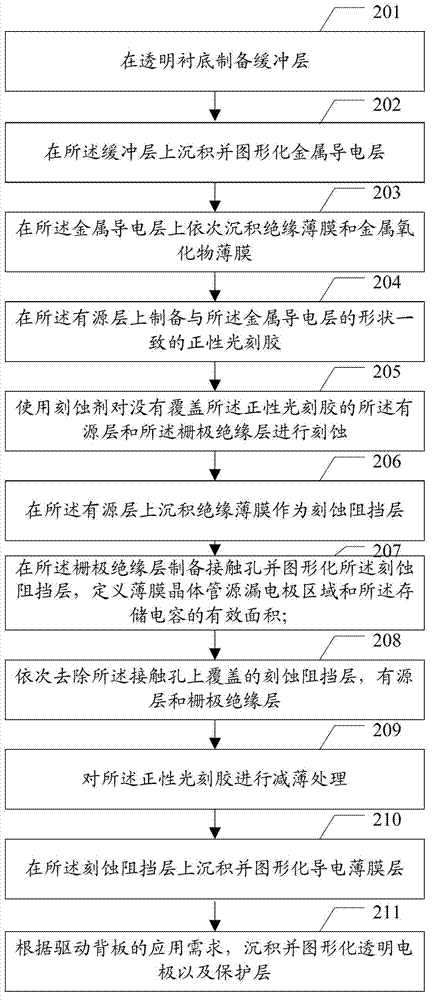

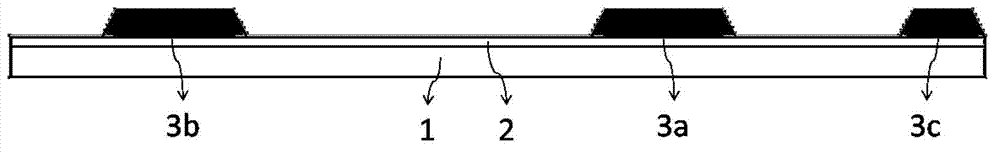

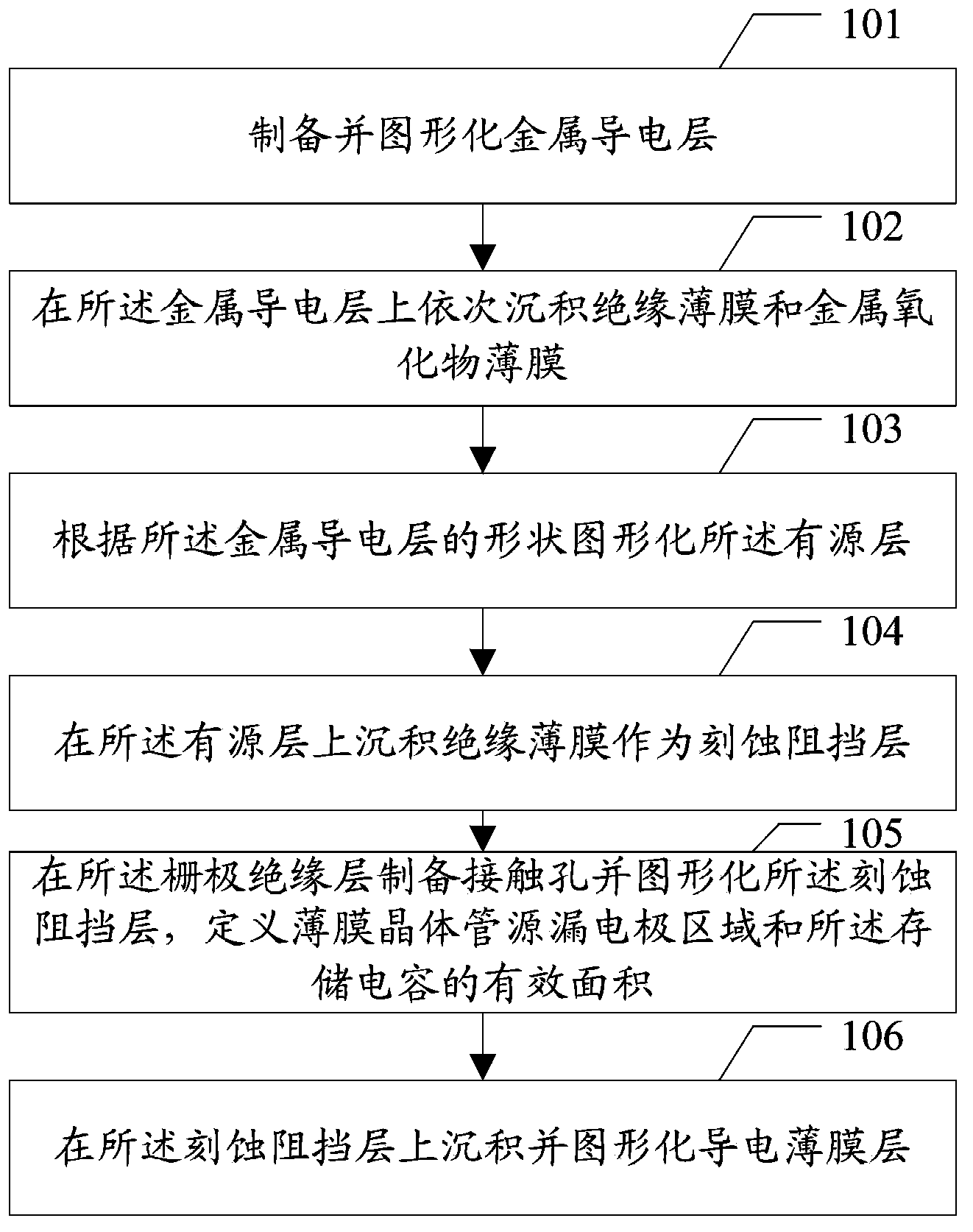

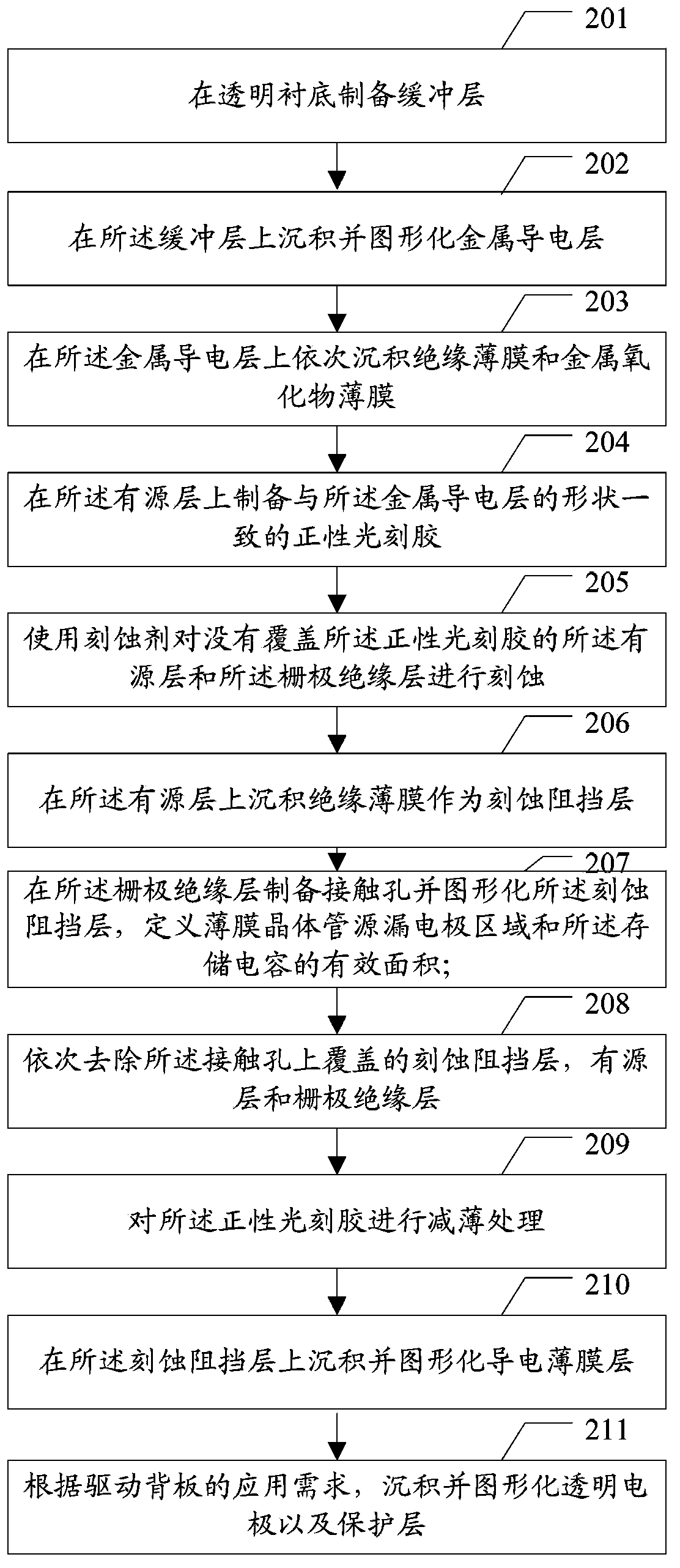

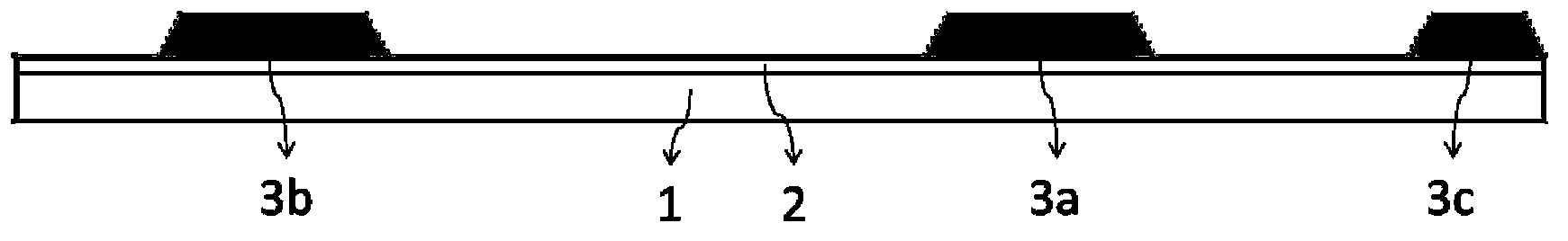

Manufacture method of thin film transistor driving rear panel

ActiveCN102768992ASimplify the number of masksReduce manufacturing costSemiconductor/solid-state device manufacturingCapacitanceSemiconductor materials

An embodiment of the invention discloses a manufacture method of a thin film transistor driving rear panel. The manufacture method is used for efficiently using a metal-oxide semiconductor material to manufacture the thin film transistor driving rear panel. The embodiment comprises preparing and imaging a metal conducting layer; sequentially depositing insulating films and metallic oxide films on the metal conducting layer to respectively serve as gate insulation layers and active layers; imaging the active layers according to shapes of the metal conducting layer; depositing the insulating films on the active layers to serve as corrosion stopping layers; using a gray level mask plate imaging process, preparing contact holes on the gate insulation layers and imaging the corrosion stopping layers, and defining source and drain electrode area of a thin film transistor and active area of storage capacitance; and depositing and imaging a conductive thin film layer on the corrosion stopping layers.

Owner:GUANG ZHOU NEW VISION OPTO ELECTRONICS TECH

Solid culturing method for increasing active product yield of antrodia camphorata

ActiveCN102356728AIncrease productionSimple processHorticultureFertilizer mixturesBiotechnologyAntrodin C

The invention discloses a solid culturing method for increasing the active product yield of antrodia camphorata by adopting a two-stage temperature control technology. The method comprises the following steps of: preparing an antrodia camphorata slant strain and a liquid seed, and inoculating the liquid seed onto a solid culture medium for culturing; controlling the culturing temperature at 26-37DEG C at the first culturing stage (0-20 days); and controlling the culturing temperature at 18-26 DEG C at the second culturing stage (20-40 days). During solid culture of active products of antrodia camphorata with a two-stage temperature control process, the yield of Antrodin C is up to 5.0-7.0 mg / g, the yield of AntrodinB is up to 1.0-2.0 mg / g, and the yield of Antroquinonol is up to 1.2-2.5 mg / g. The two-stage temperature control technology for the active products of antrodia camphorata provided by the invention is simple and efficient and has an important industrial application value; and meanwhile, the production of other active metabolic products of antrodia camphorata have certain enlightening meanings.

Owner:JIANGNAN UNIV

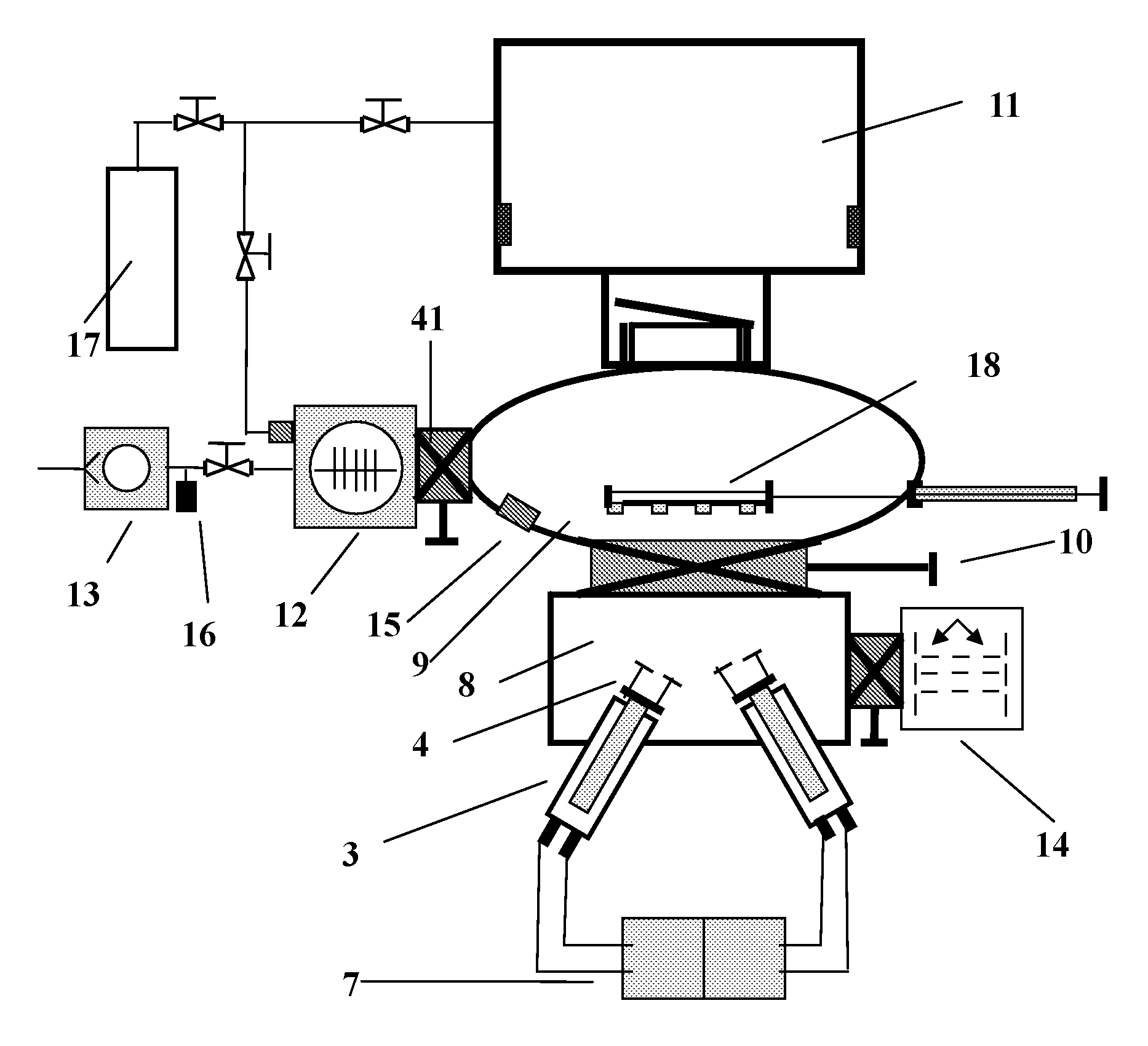

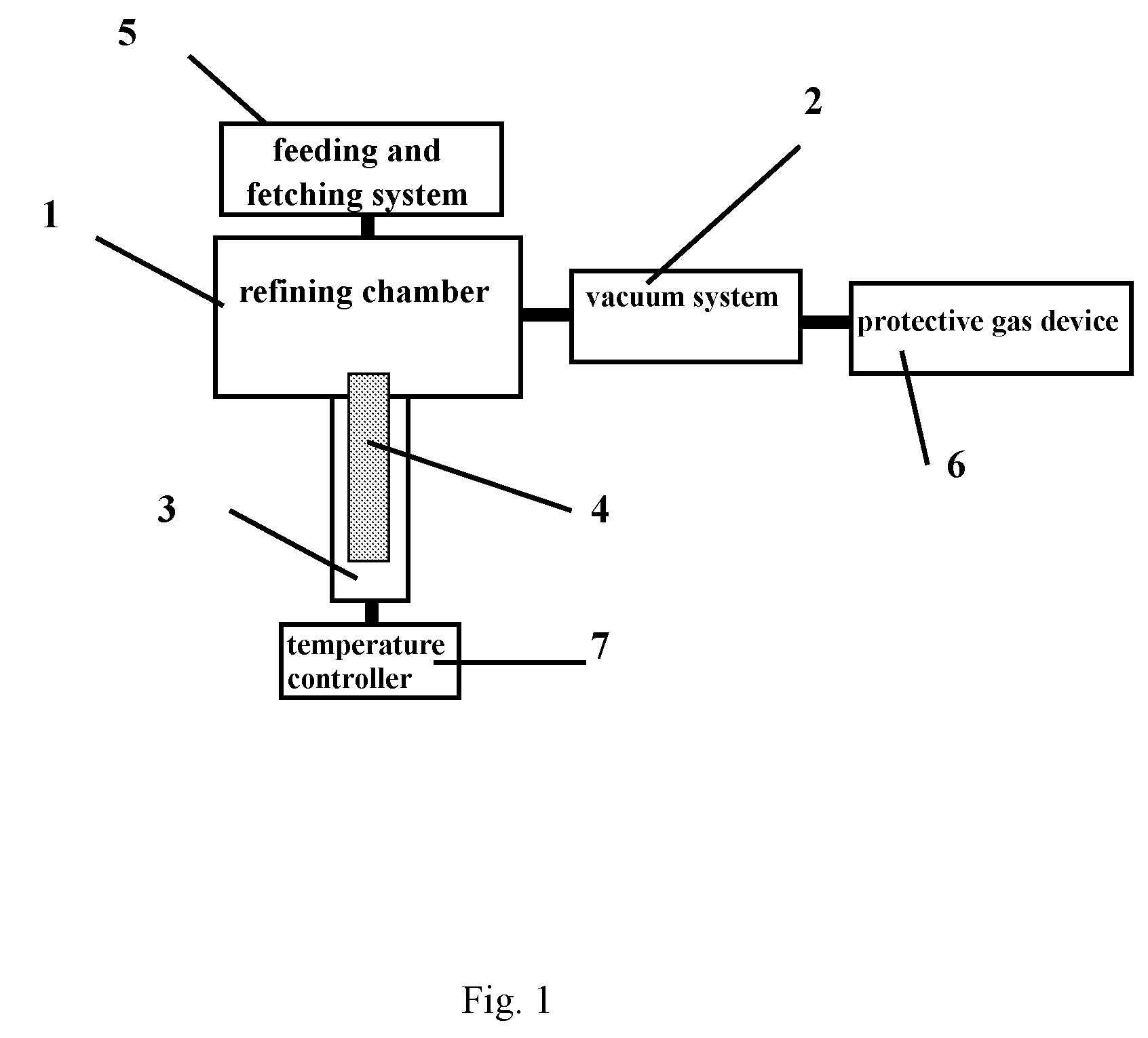

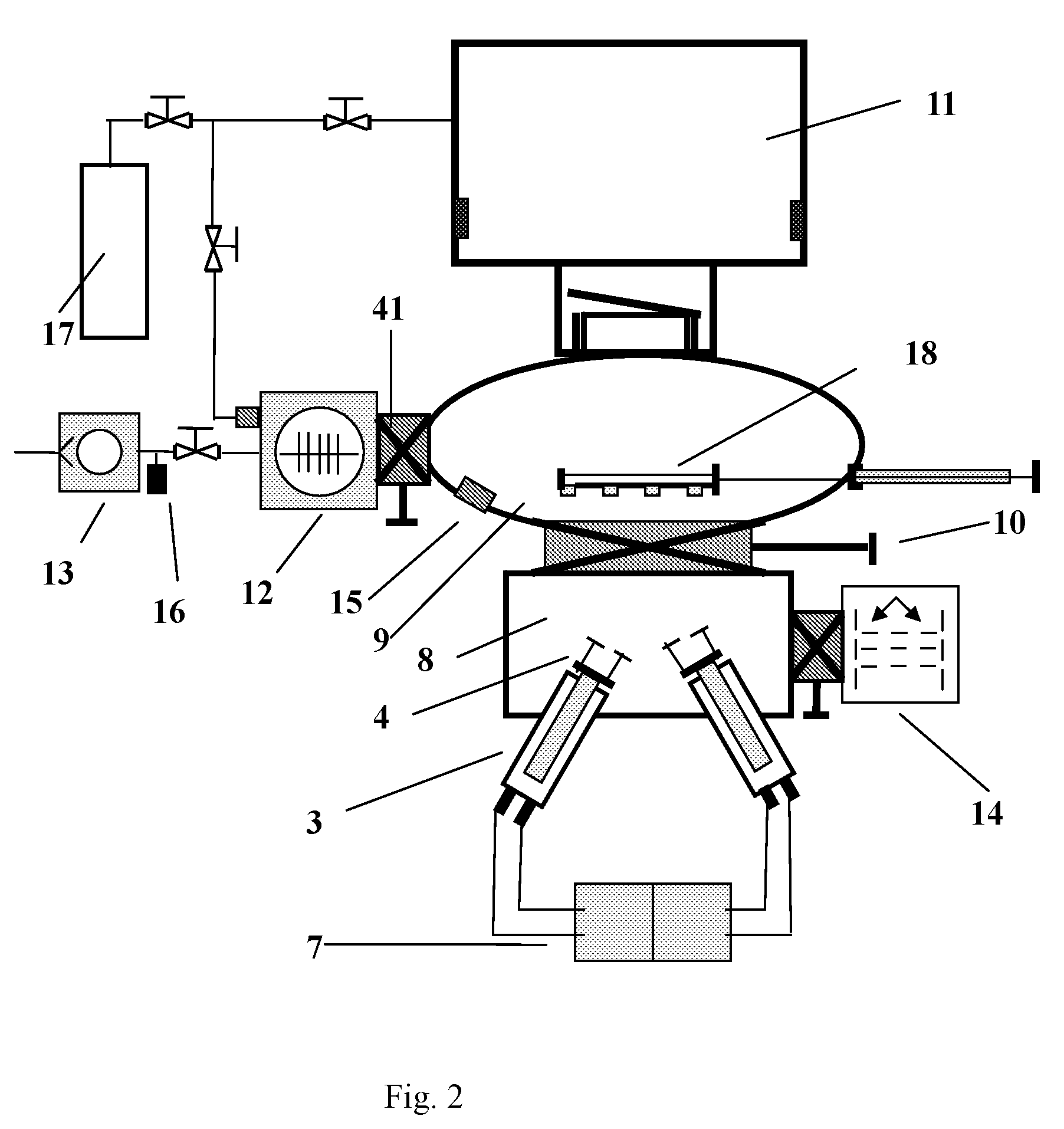

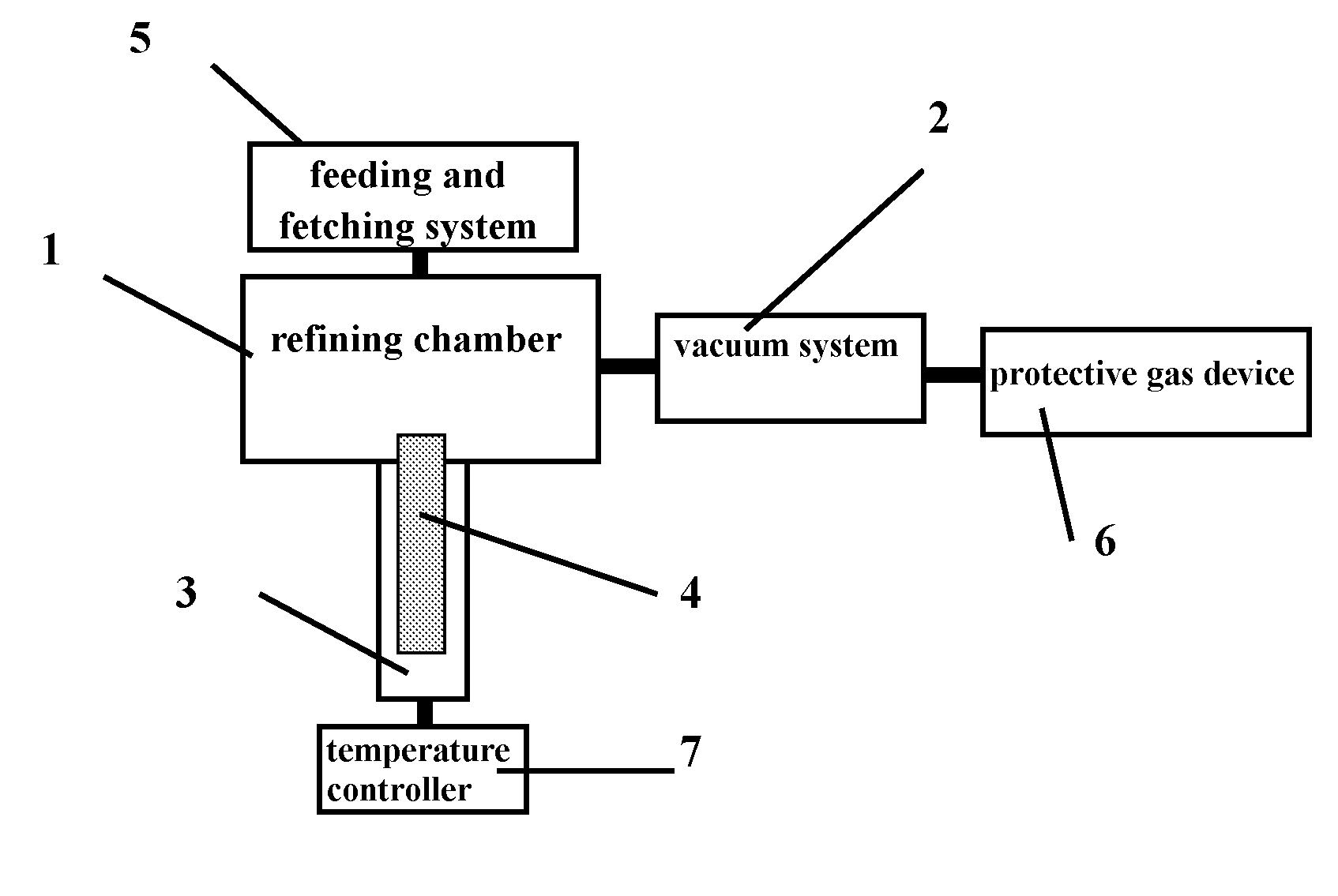

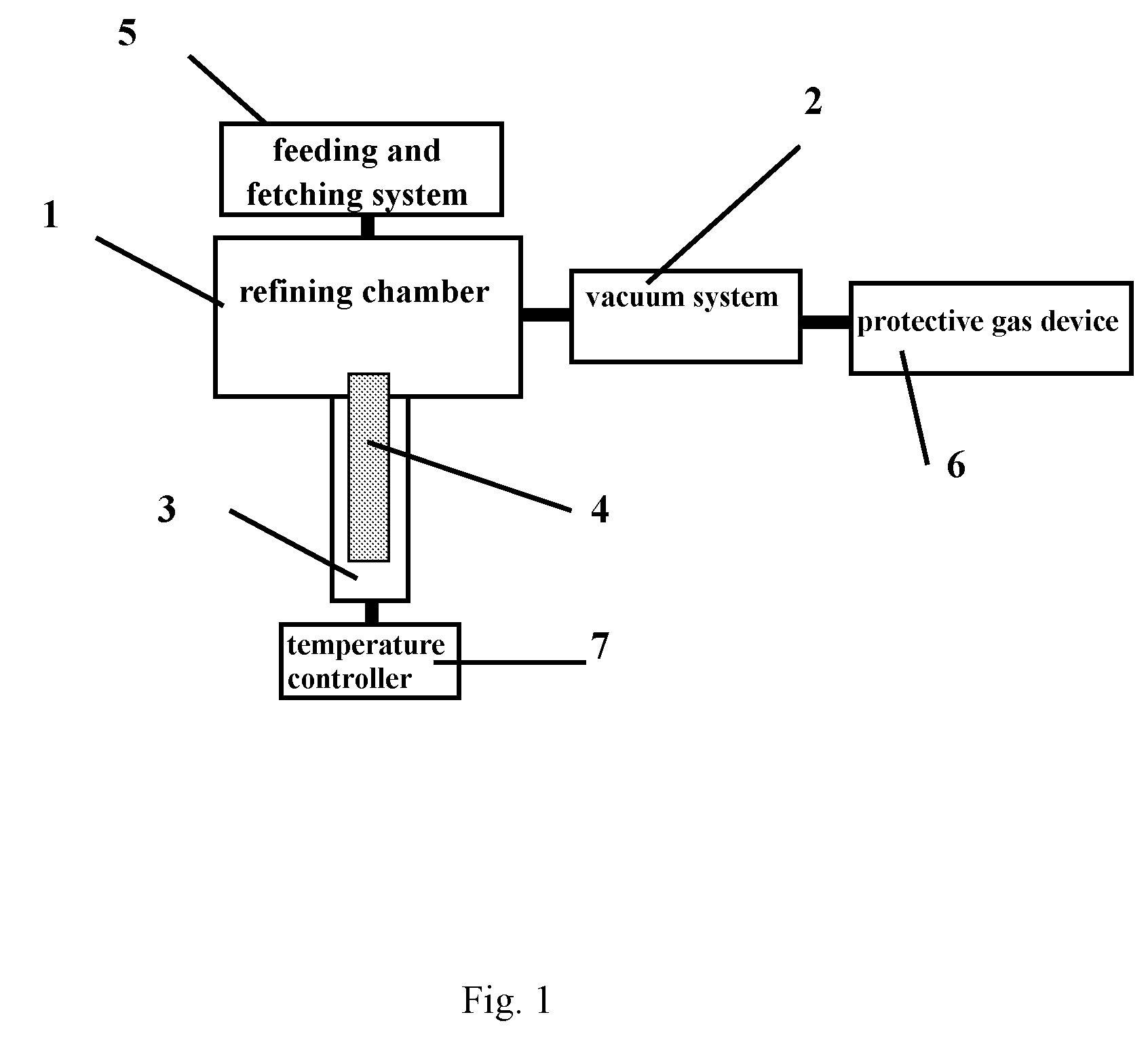

High Vacuum In-Situ Refining Method for High-Purity Materials and an Apparatus Thereof

InactiveUS20080257109A1Improve purification effectEnvironmentally friendlyBlast furnace detailsDust arrestersVapor pressureDiffusion

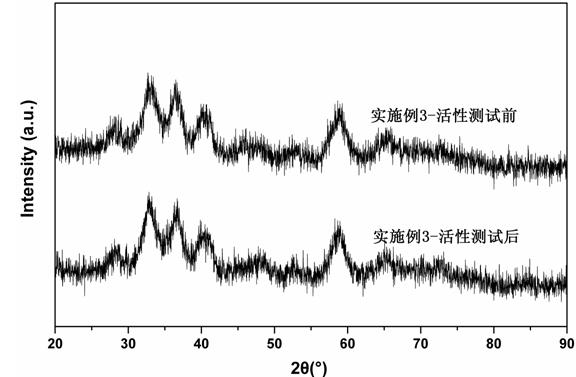

The present invention concerns a high vacuum in-situ refining method for high-purity and superhigh-purity materials and the apparatus thereof, characterized in heating the upper part and lower part of crucible separately using double-heating-wires diffusion furnace under vacuum, thereby forming the temperature profile which is high at upper part and low at lower part of crucible, or in reverse during different stages; then heating the crucible in two steps to remove impurities with high saturation vapor pressure and low saturation vapor pressure respectively in efficiency; and obtaining high-purity materials eventually. The whole procedure is isolated from atmosphere, reducing contamination upon stuff remarkably. The present invention could provide products with high-quality and high production capacity, which are stable in performance, therefore is reliable and free from contamination. The present invention is appropriate for manufacture of high-purity and superhigh-purity materials, particularly for manufacture of high-activity high-purity materials.

Owner:SHENGZHOU GUOSHENG NEW ENERGY TECH

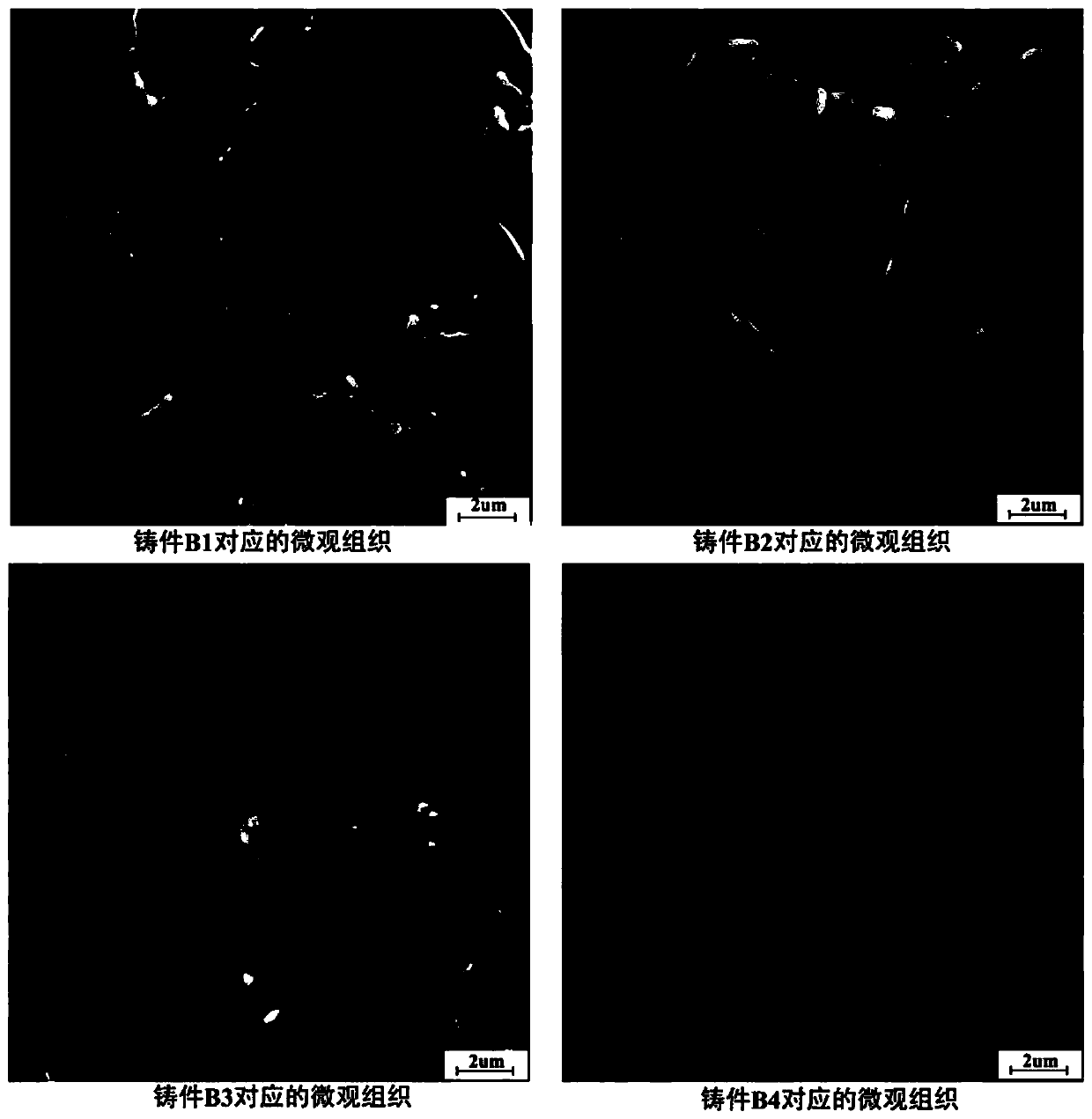

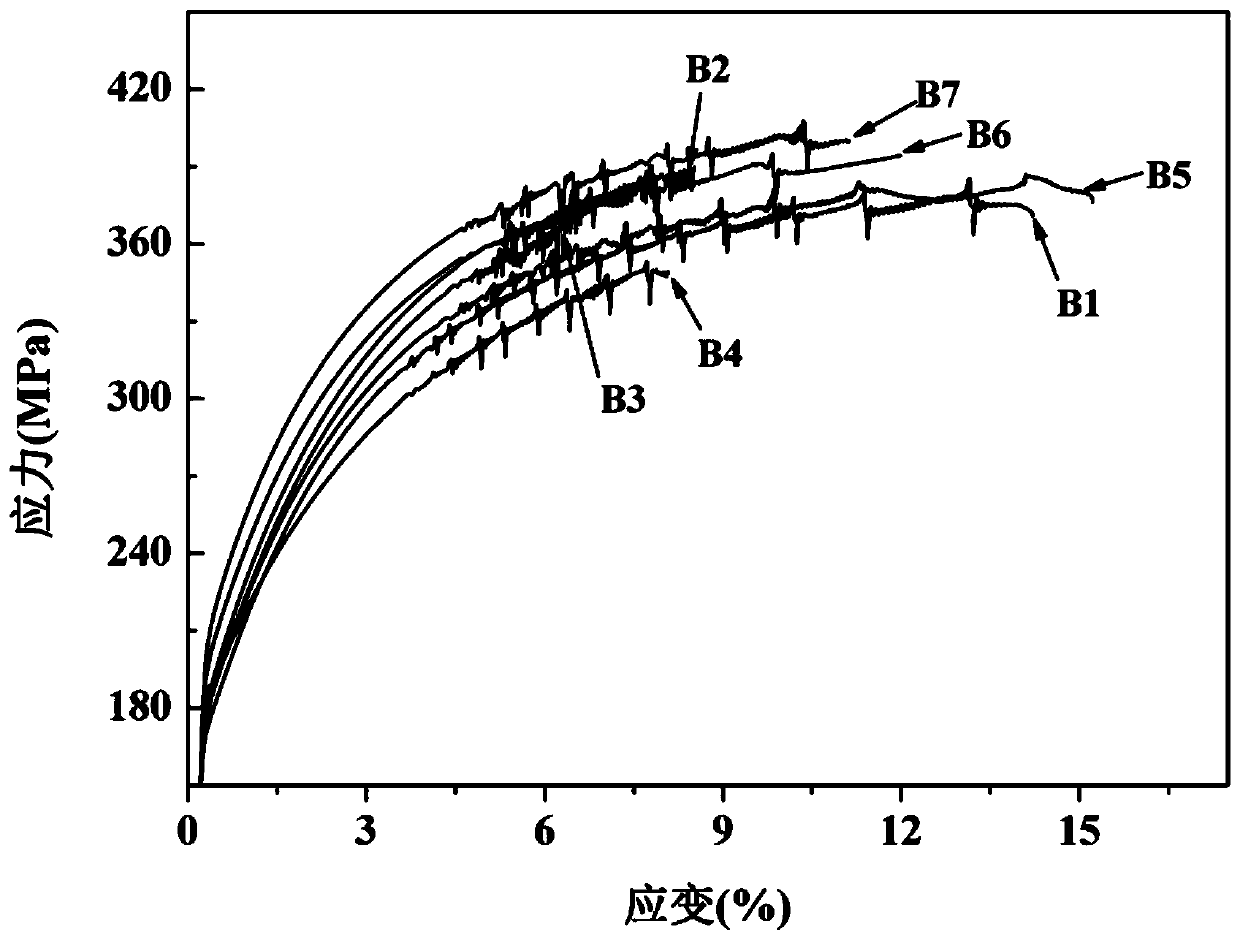

Non-heat treatment strengthened high-strength high-toughness pressure casting aluminum-magnesium-silicon alloy and preparing method thereof

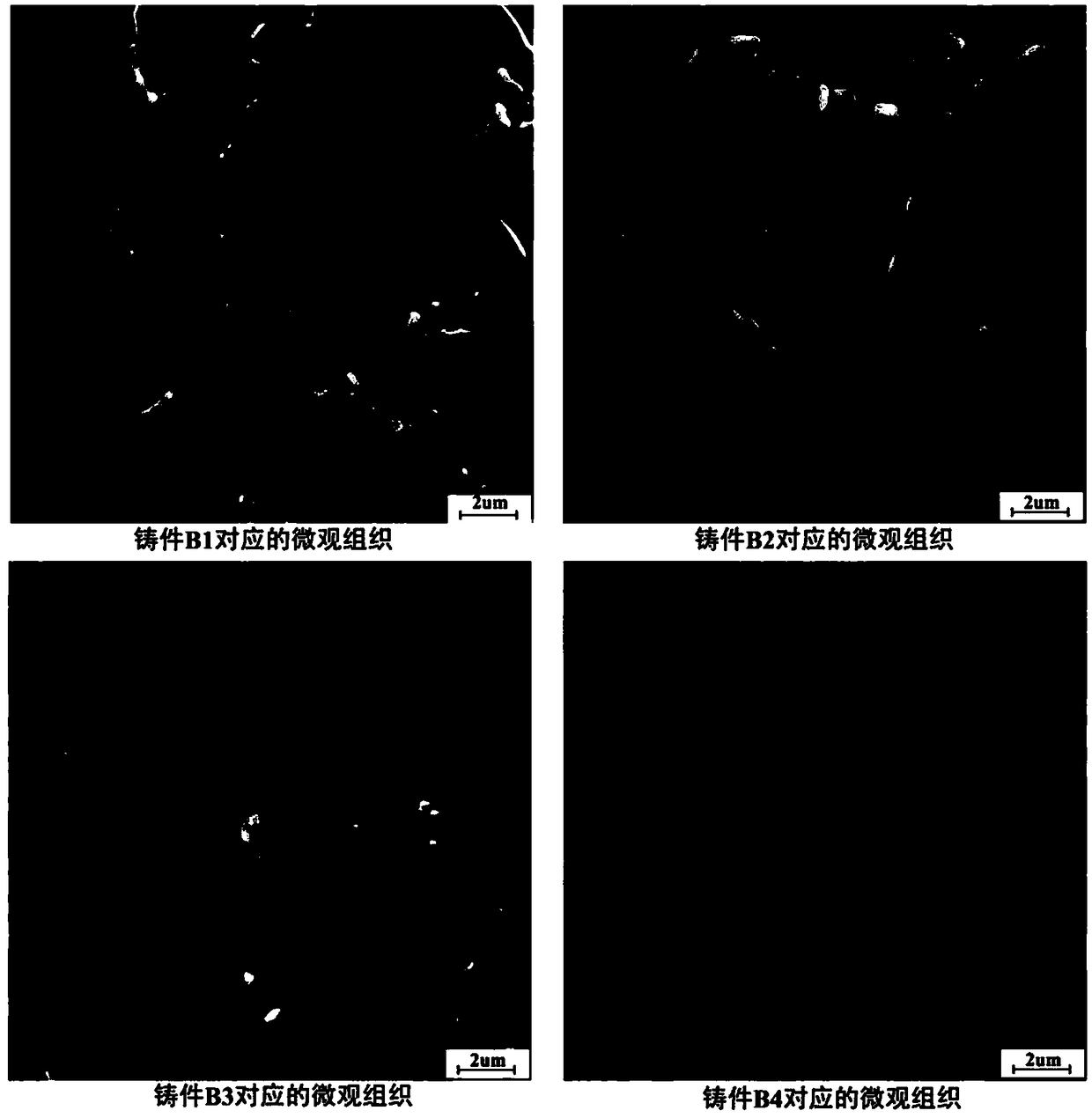

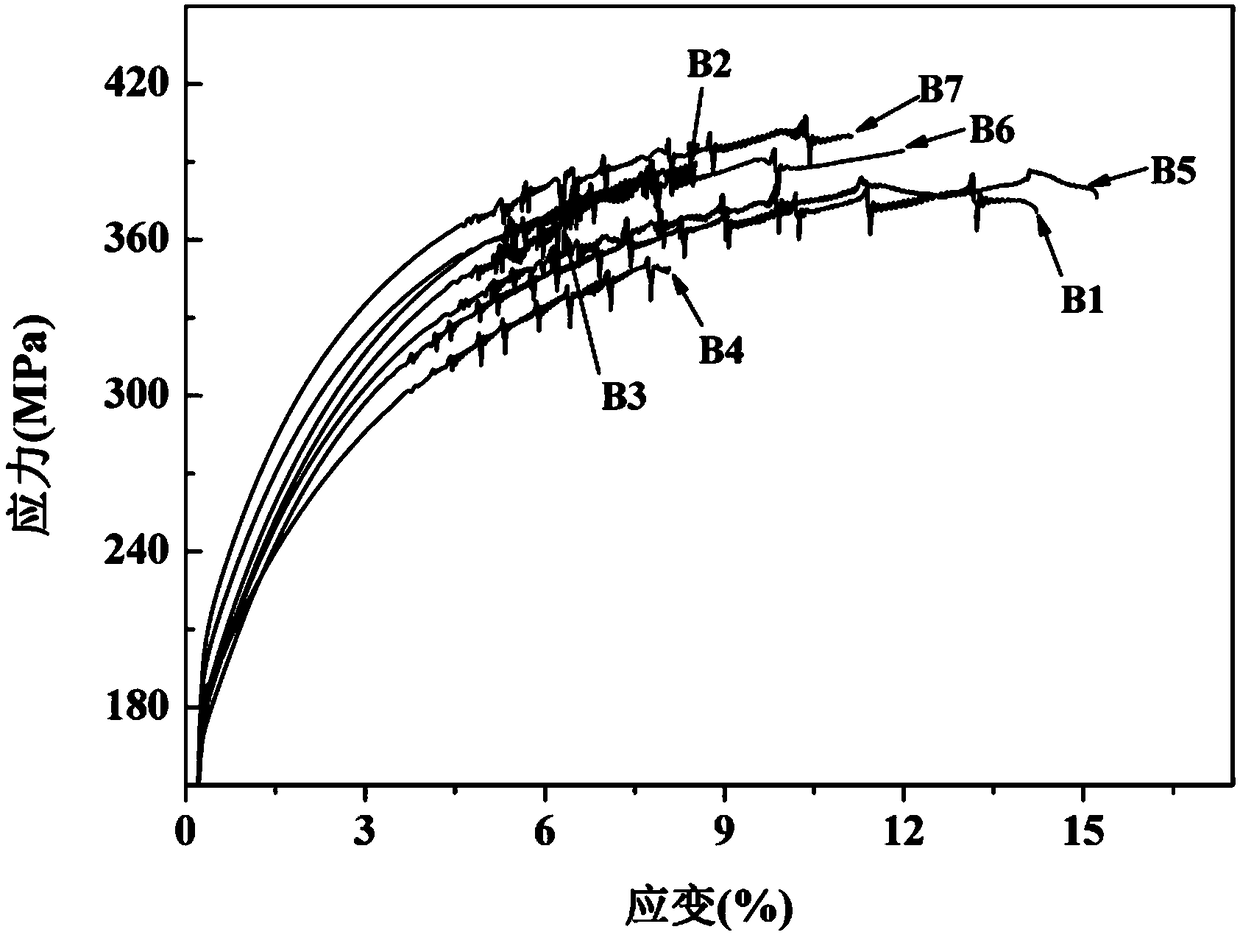

ActiveCN108754256AImportant industrial application valueMeet application needsThin walledPressure casting

The invention relates to a non-heat-treatment strengthened high-strength high-toughness pressure casting aluminum-magnesium-silicon alloy, and a preparing method thereof. The pressure casting aluminum-magnesium-silicon alloy comprises, by weight percent, 6.0 to 8.0% of Mg, 2.0 to 3.6% of Si, 0.6 to 0.9% of Mn, 0.15 to 0.20% of Ti, 0.004 to 0.006% of Be, 0.003 to 0.01% of Ca, 0.03 to 0.1% of V, 0.02 to 0.1% of Zr, 0.01 to 0.2% of RE, smaller than or equal to 0.4% of the sum of the total amount of other impurities and the balance Al. the alloy has the high strength and high toughness under the casting-state condition, good pressure casting can be achieved, and the application needs of large thin-wall car body structural parts of the car industry can be greatly met.

Owner:SHANGHAI JIAO TONG UNIV +1

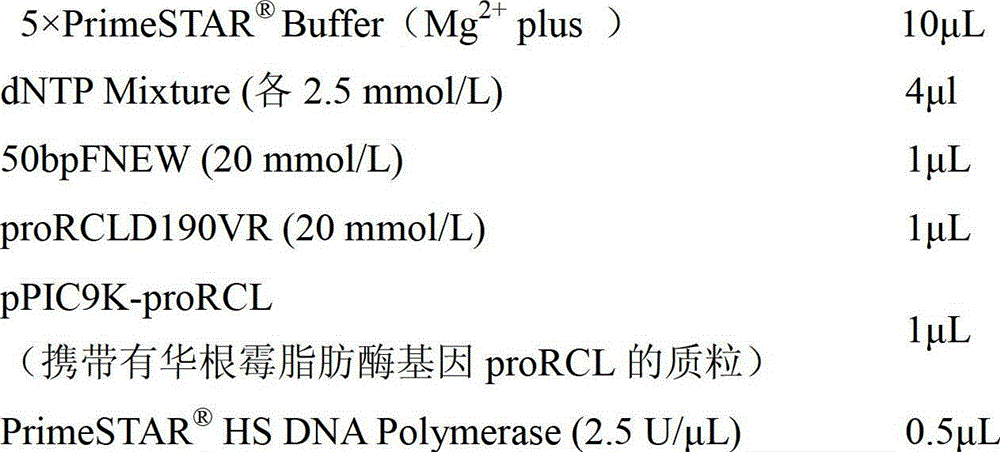

Lipase mutant with increased optimum temperature and application of lipase mutant with increased optimum temperature

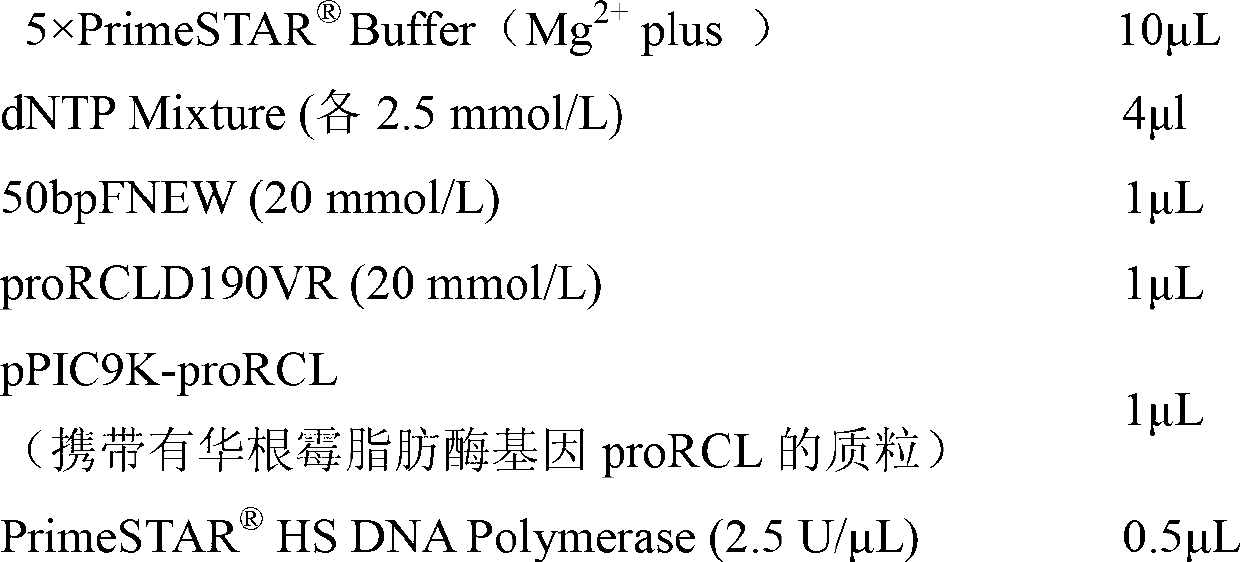

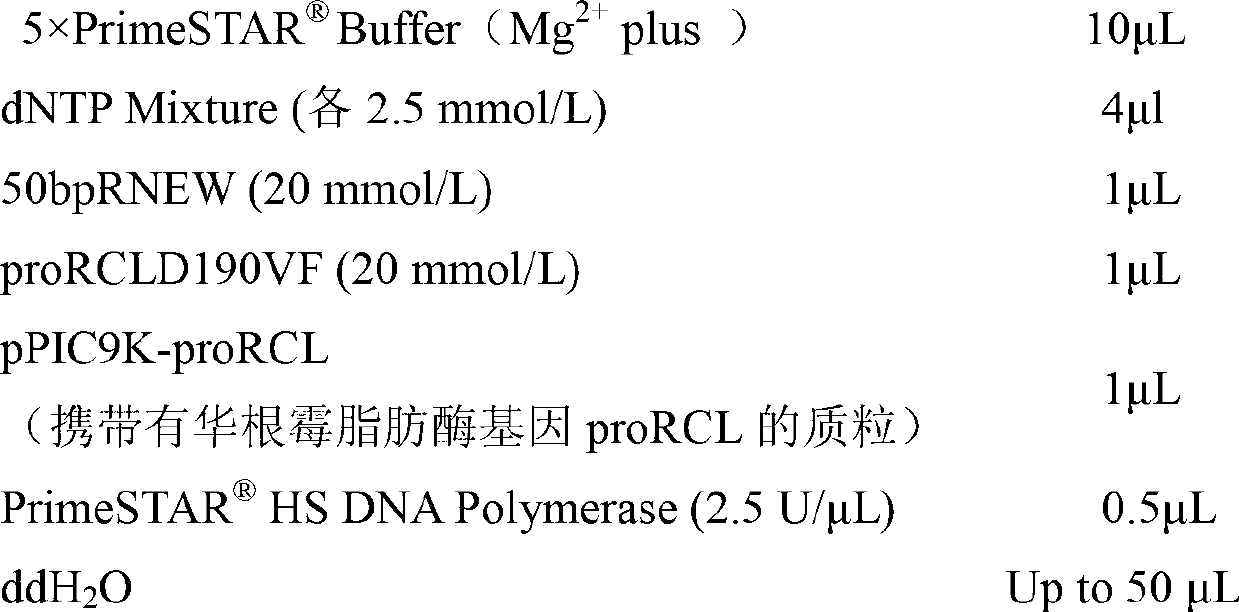

ActiveCN102994471AOptimum temperature increaseImportant industrial application valueFungiHydrolasesRhizopusGenetic engineering

The invention discloses a lipase mutant with increased optimum temperature, which belongs to the technical field of enzymatic genetic engineering. The lipase mutant with increased optimum temperature disclosed by the invention is obtained through taking rhizopus chinensis China center for type culture collection (CCTCC) M201021 lipase as a parent and utilizing a molecular biological technique, and the mutant amino acid of the mutant is Asp310Val. The optimum temperature of the lipase mutant is increased compare with the optimum temperature of the parent of rhizopus chinensis lipase and has an important industrial application value.

Owner:宁夏夏盛实业集团有限公司

Method for preparing small-molecular weight hyaluronic acid by adding hyaluronate lyase in course of fermentation

InactiveCN101294179ASimple methodImportant industrial application valueMicroorganism based processesFermentationChemistryReference sample

The invention discloses a method for producing hyaluronic acid with small molecular weight by adding hyaluronidase in fermentation process, which belongs to the technology field of the application of enzymolysis reaction in optimization of fermentation process. In the method, hyaluronidase (0.05 to 0.25 g / L) is added in the fermentation process (8 h) to degrade hyaluronic acid, so that the viscosity of a fermentation broth decreases from 300 cp of a reference sample (without hyaluronidase) to 50 to 150 cp, the dissolved oxygen concentration is improved from 0 to 1% of the reference sample to 10 to 15%, the output of hyaluronic acid is improved from 5.0 g / L of the reference sample to 6.0 to 7.0 g / L, and the molecular weight of the hyaluronic acid decreases from 1,300 kDa of the reference sample to 20 to 100 kDa. The inventive method is simple and efficient, and has important industrial application value. The decrease of the viscosity of the fermentation broth results in the improvement of downstream purification efficiency and the reduction of production cost. The hyaluronic acid with small molecular weight produced by the method can be applied to the fields of medicines and healthy food.

Owner:JIANGNAN UNIV

Method for preparing small-molecular weight hyaluronic acid by adding hydrogen phosphide and ascorbic acid in course of fermentation

InactiveCN101294180ASimple methodImportant industrial application valueMicroorganism based processesFermentationHydrogen phosphideDegradation reaction

The invention discloses a method for producing hyaluronic acid with small molecular weight by adding hydrogen peroxide and ascorbic acid in fermentation process, which belongs to the technology field of the application of oxidative-reductive degradation reaction in optimization of fermentation process. In the method, hydrogen peroxide (0.1 to 1.0 mmol / g hyaluronic acid) and ascorbic acid (0.05 to 0.5 mmol / g hyaluronic acid) are added in the fermentation process (8 h) to degrade hyaluronic acid, so that the viscosity of a fermentation broth decreases from reference 300 cp (without hyaluronidase) to 100 to 200 cp, the dissolved oxygen concentration is improved from reference 0 to 1% to 5 to 10%, the output of hyaluronic acid is improved from reference 5.0 g / L to 5.5 to 6.4 g / L, and the molecular weight of the hyaluronic acid decreases from reference 1,300 kDa to 80 to 200 kDa. The inventive method is simple and efficient, and has important industrial application value. The decrease of the viscosity of the fermentation broth results in the improvement of downstream purification efficiency and the reduction of production cost. The hyaluronic acid with small molecular weight produced by the method can be applied to the fields of medicines and healthy food.

Owner:JIANGNAN UNIV

High vacuum in-situ refining method for high-purity materials and an apparatus thereof

InactiveUS7753987B2Good effectEnvironmentally friendlyCalcium/strontium/barium compoundsBlast furnace detailsCrucibleUltra high purity

Owner:SHENGZHOU GUOSHENG NEW ENERGY TECH

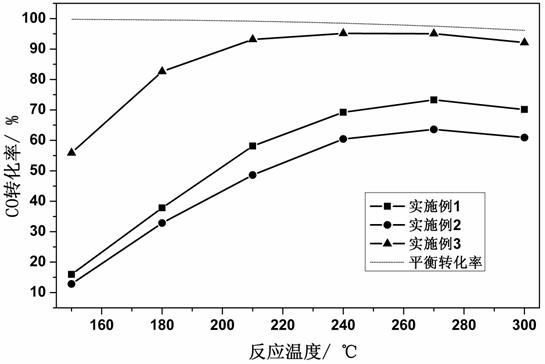

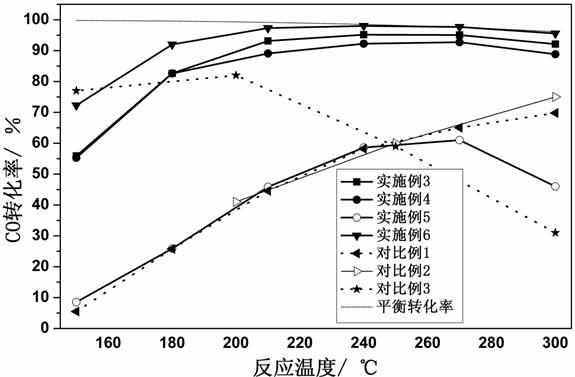

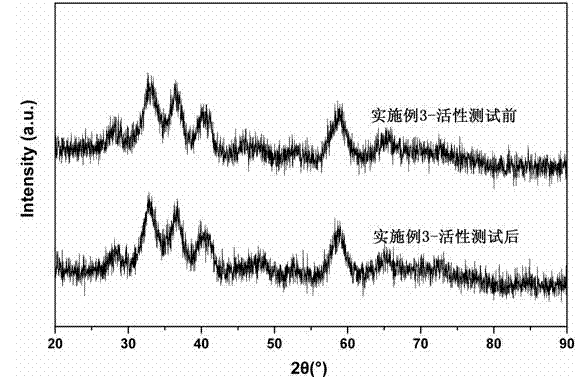

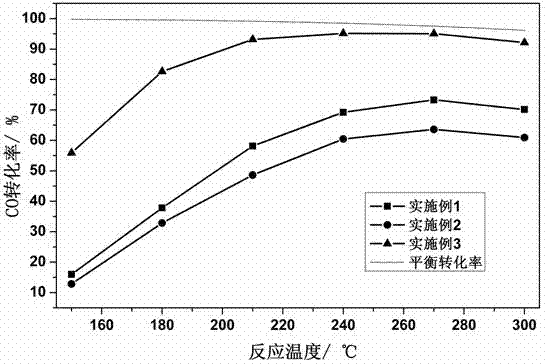

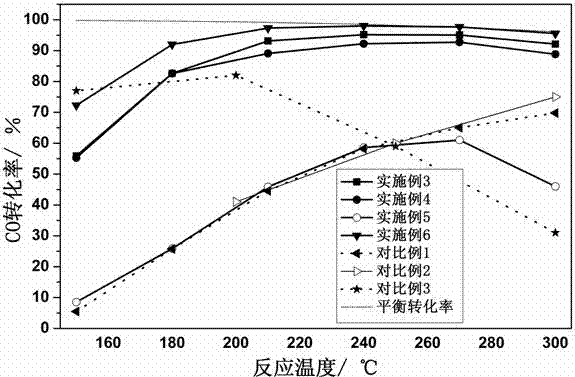

Catalyst for low-temperature water-gas-shift reaction under hydrogenous reformed gas and preparation method thereof

InactiveCN101954279AImprove the catalytic activity of the shift reactionLarge specific surface areaHydrogen separation using solid contactCatalyst activation/preparationActive componentWater-gas shift reaction

The invention relates to a catalyst for a low-temperature water-gas-shift reaction under a hydrogenous reformed gas and a preparation method thereof. The catalyst of the invention comprises the following component in percentage by weight: 0.1 to 3 percent of aurum (Au) and 97 to 99.9 percent of zirconium oxide (ZrO2), wherein the Au is an active component; and the ZrO2 is a carrier. The ZrO2 carrier prepared by the method has larger specific surface area and larger pore volume, so the active component Au can be dispersed better. The catalyst of the invention still has higher low-temperature water-gas-shift catalytic activity under the condition of lower Au mass content, for example, when the Au weight content reduced to 1 percent, the carbon monoxide (CO) conversion rate of the Au / ZrO2 catalyst is still near the balance conversion rate at the temperature of between 210 and 300 DEG C. The catalyst of the invention has the advantages of wide using conditions and particular suitability for a high airspeed hydrogenous reformed gas atmosphere.

Owner:FUZHOU UNIV

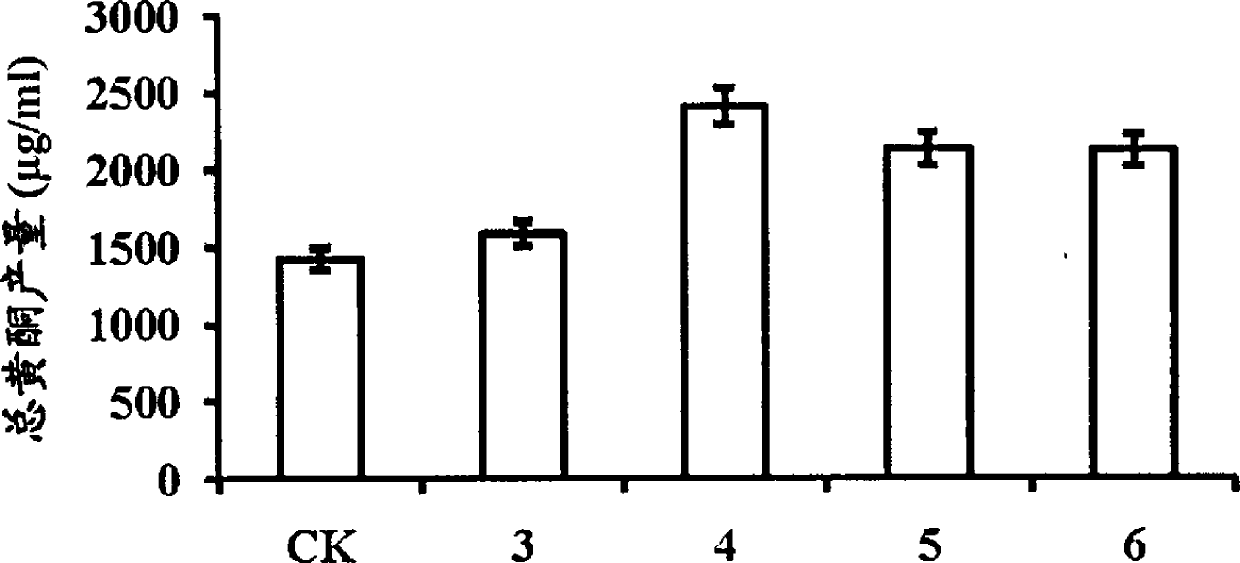

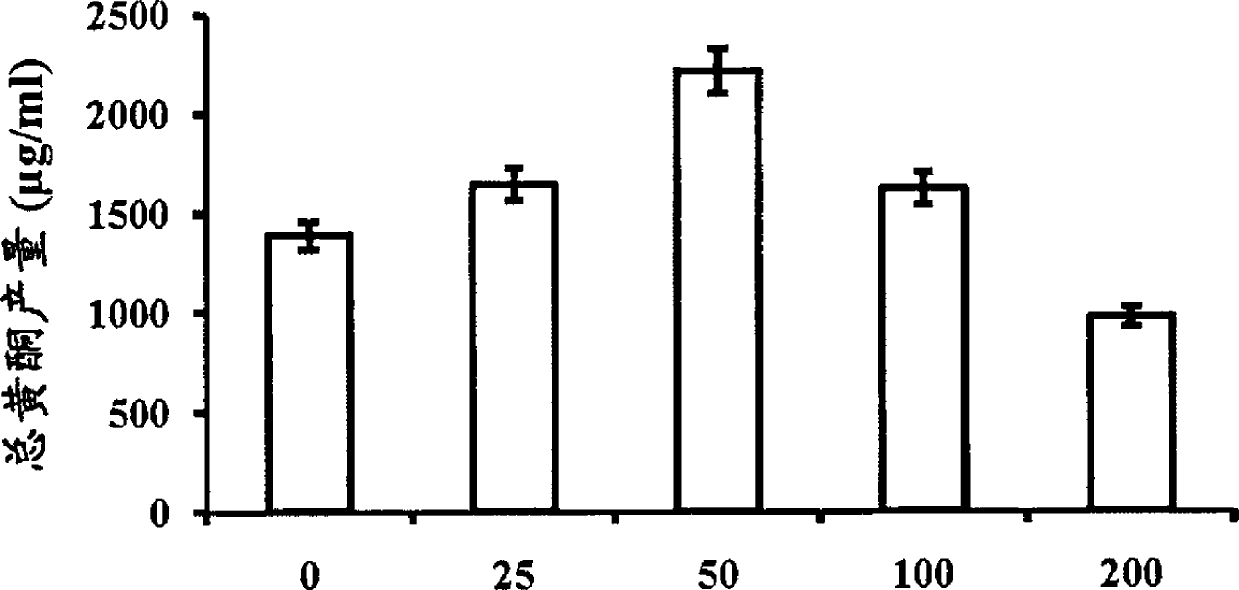

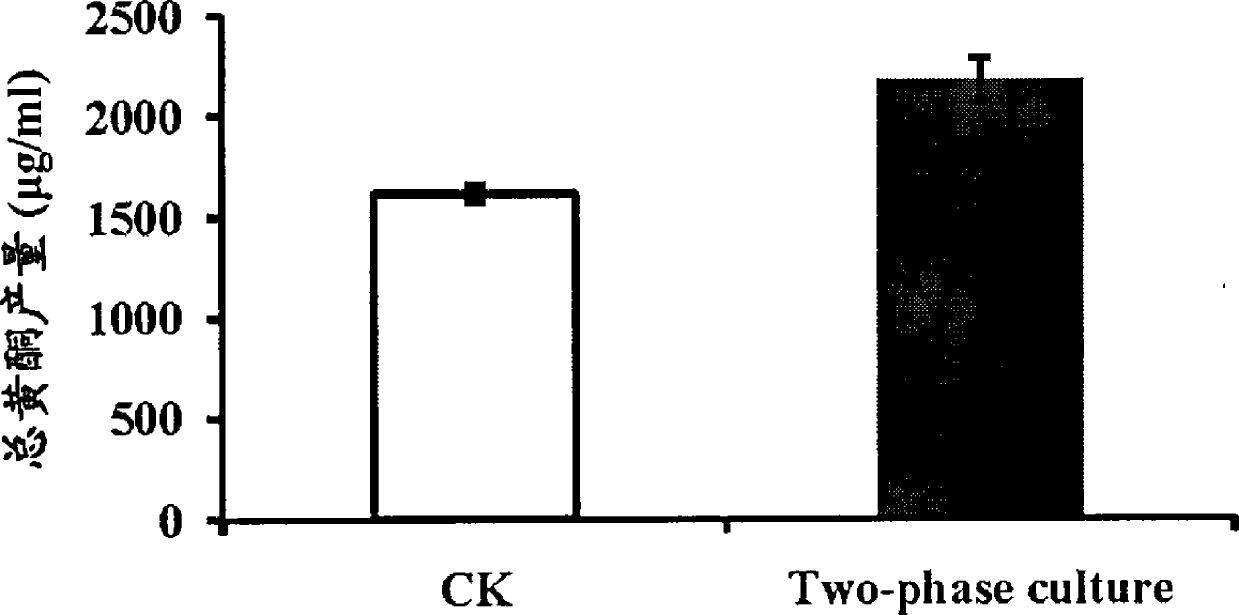

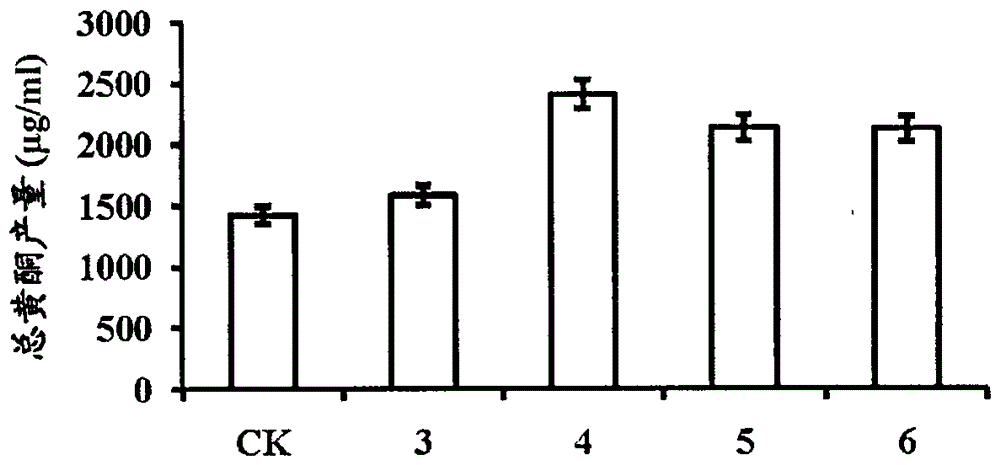

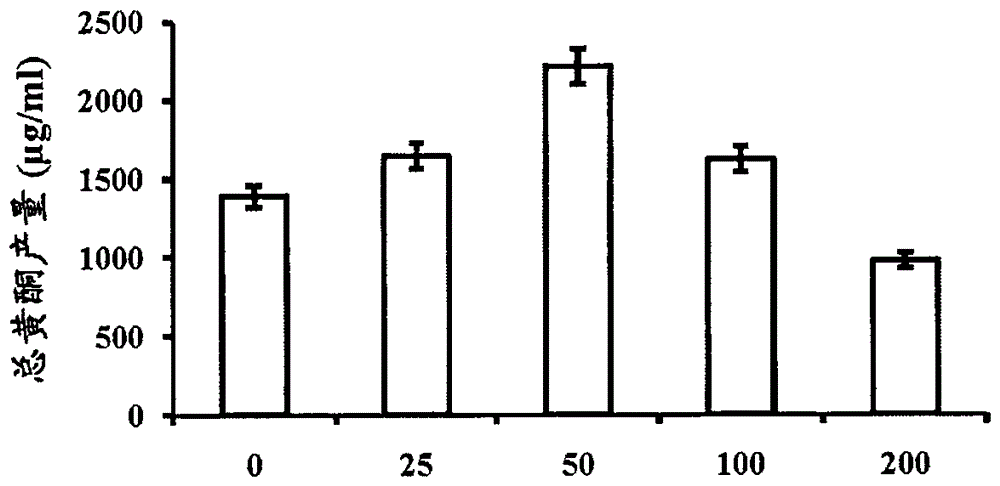

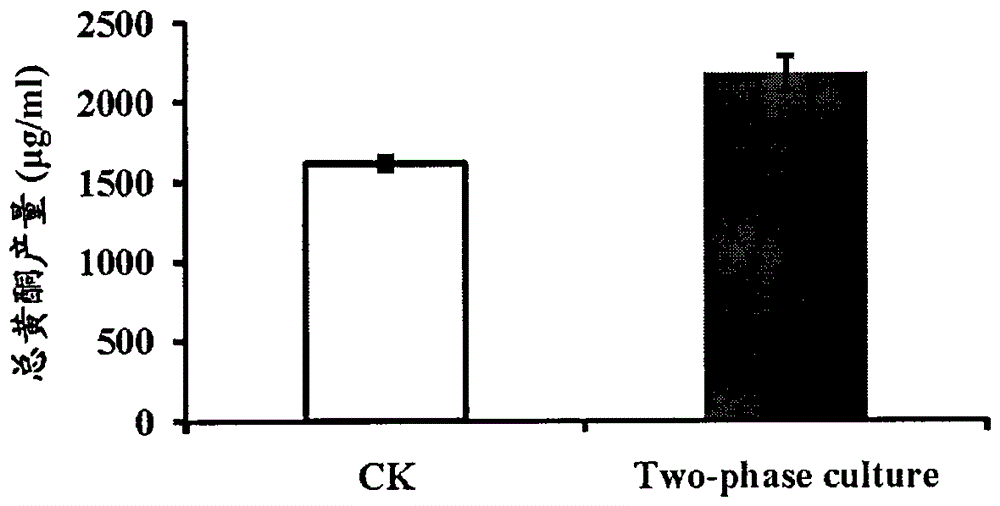

Process for producing flavone through liquid-solid double-phase phellinus igniarius culture

InactiveCN103627728AIncrease productionThe cultivation process is simpleMicroorganism based processesFermentationBiotechnologyCulture fluid

The present invention relates to a process for producing flavone through liquid-solid double-phase culture of medicinal mushroom phellinus igniarius, and belongs to the technical field of biological fermentation engineering. According to the present invention, mainly during a phellinus igniarius liquid fermentation process, a macroporous absorption resin is added to a culture liquid to establish a liquid-solid double-phase culture system so as to improve a flavone yield; with the double-phase culture process, the flavone yield can be up to 2174.35 mug / ml and is increased by 35% compared with the control; and the process has characteristics of simple operation and strong generalization, and is especially suitable for large-scale higher fungi fermentation and active substance production.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

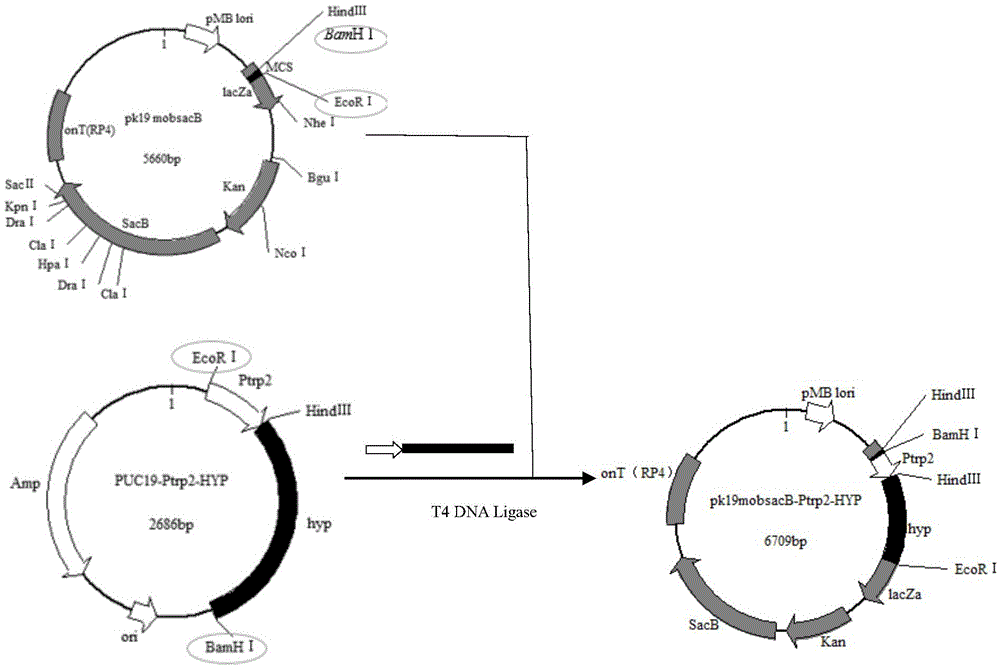

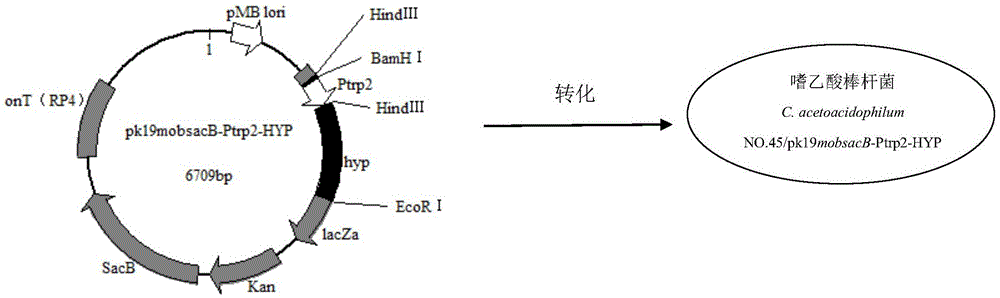

Method for producing trans-4-hydroxyl-L-proline by means of fermentation by aid of recombinant corynebacterium acetoacidophilum

InactiveCN105603017AImportant industrial application valueOxidoreductasesFermentationAcetic acidHydroxyproline

The invention discloses a method for producing trans-4-hydroxyl-L-proline by means of fermentation by the aid of recombinant corynebacterium acetoacidophilum. Recombinant plasmids carried by the recombinant corynebacterium acetoacidophilum have proline hydroxylase genes (P4H) capable of catalyzing proline to generate trans-4-hydroxyproline. The method has the advantage that the free L-proline can be converted into the trans-4-hydroxyl-L-proline by the aid of proline-4-hydroxylase in cells of the recombinant corynebacterium acetoacidophilum under the condition of existence of alpha-ketoglutaric acid and ferrous ions. The invention further discloses application of corynebacterium acetoacidophilum to producing the trans-4-hydroxyl-L-proline.

Owner:JIANGNAN UNIV

Solid culturing method for increasing active product yield of antrodia camphorata

ActiveCN102356728BIncrease productionSimple processHorticultureFertilizer mixturesBiotechnologyAntrodin C

The invention discloses a solid culturing method for increasing the active product yield of antrodia camphorata by adopting a two-stage temperature control technology. The method comprises the following steps of: preparing an antrodia camphorata slant strain and a liquid seed, and inoculating the liquid seed onto a solid culture medium for culturing; controlling the culturing temperature at 26-37DEG C at the first culturing stage (0-20 days); and controlling the culturing temperature at 18-26 DEG C at the second culturing stage (20-40 days). During solid culture of active products of antrodia camphorata with a two-stage temperature control process, the yield of Antrodin C is up to 5.0-7.0 mg / g, the yield of AntrodinB is up to 1.0-2.0 mg / g, and the yield of Antroquinonol is up to 1.2-2.5 mg / g. The two-stage temperature control technology for the active products of antrodia camphorata provided by the invention is simple and efficient and has an important industrial application value; and meanwhile, the production of other active metabolic products of antrodia camphorata have certain enlightening meanings.

Owner:JIANGNAN UNIV

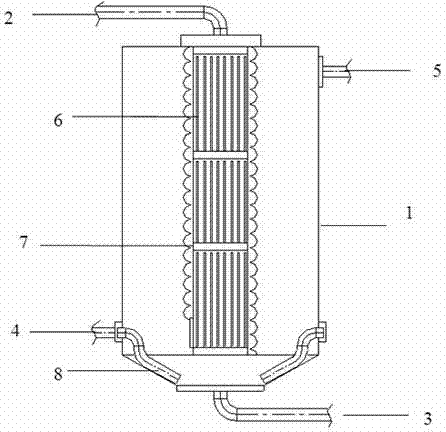

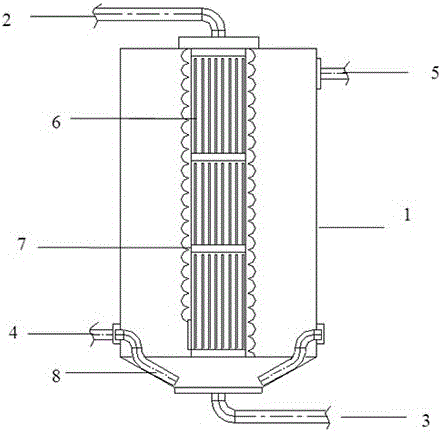

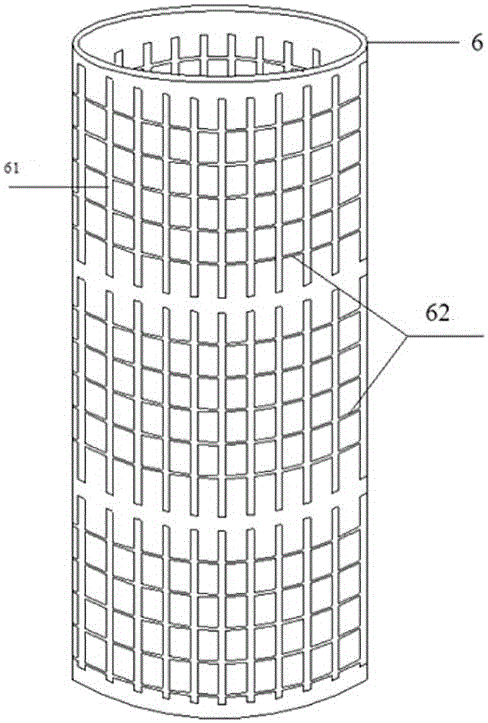

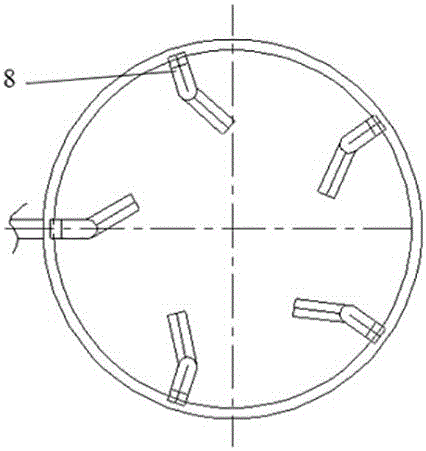

Self-forming membrane filtering method and device for wastewater treatment

InactiveCN104709969ALow costSimple processSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisSolid suspensionSelf forming

The invention discloses a self-forming membrane filtering method and device for wastewater treatment. According to the technical scheme, a fixed membrane carrier is arranged in an airtight cylinder; solid suspensions (SS) in wastewater are coagulated into relatively large flocculent particles under the action of a flocculant; the flocculent particles are attached to the cylinder or prism membrane carrier under preset pressure and cyclone action to automatically form a membrane; the wastewater is filtered, and the filtered wastewater is discharged through the self-forming membrane layer. The self-forming membrane filtering device comprises the airtight cylinder, wherein a back-flushing device is arranged at the top of the airtight cylinder; a mud discharging channel is formed in the bottom of the airtight cylinder; a water inlet is arranged in the side near the bottom end of the airtight cylinder; a water outlet is arranged in one side near the top end of the airtight cylinder; the membrane carrier connected respectively with the back-flushing device and the water inlet is arranged in the airtight cylinder; a cyclone pipe communicated with the water inlet is arranged at the bottom end in the airtight cylinder. The method is simple in treatment technology, small in occupied area, low in cost, high in efficiency and great in energy-saving effect.

Owner:LIAONING JIECHEN ENVIRONMENTAL PROTECTION EQUIP CO LTD

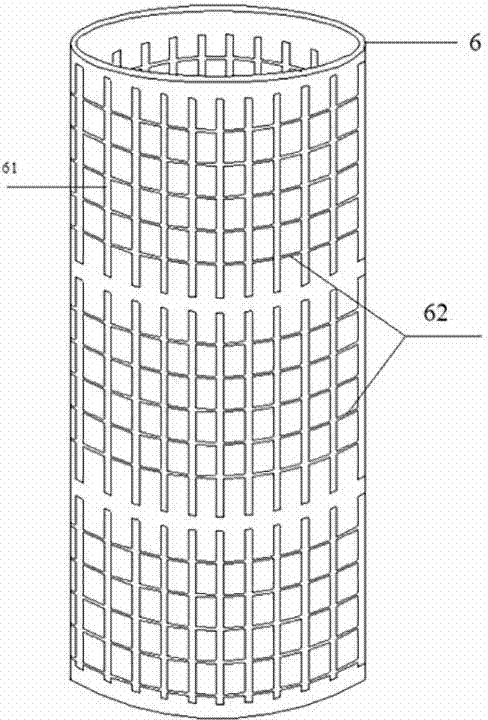

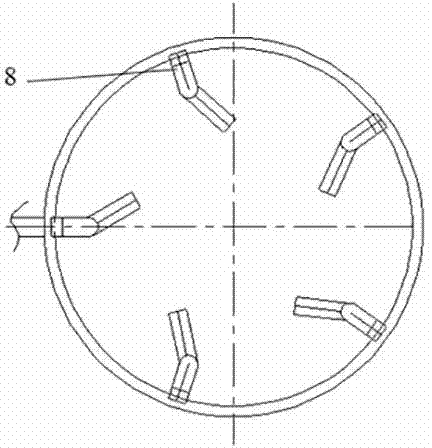

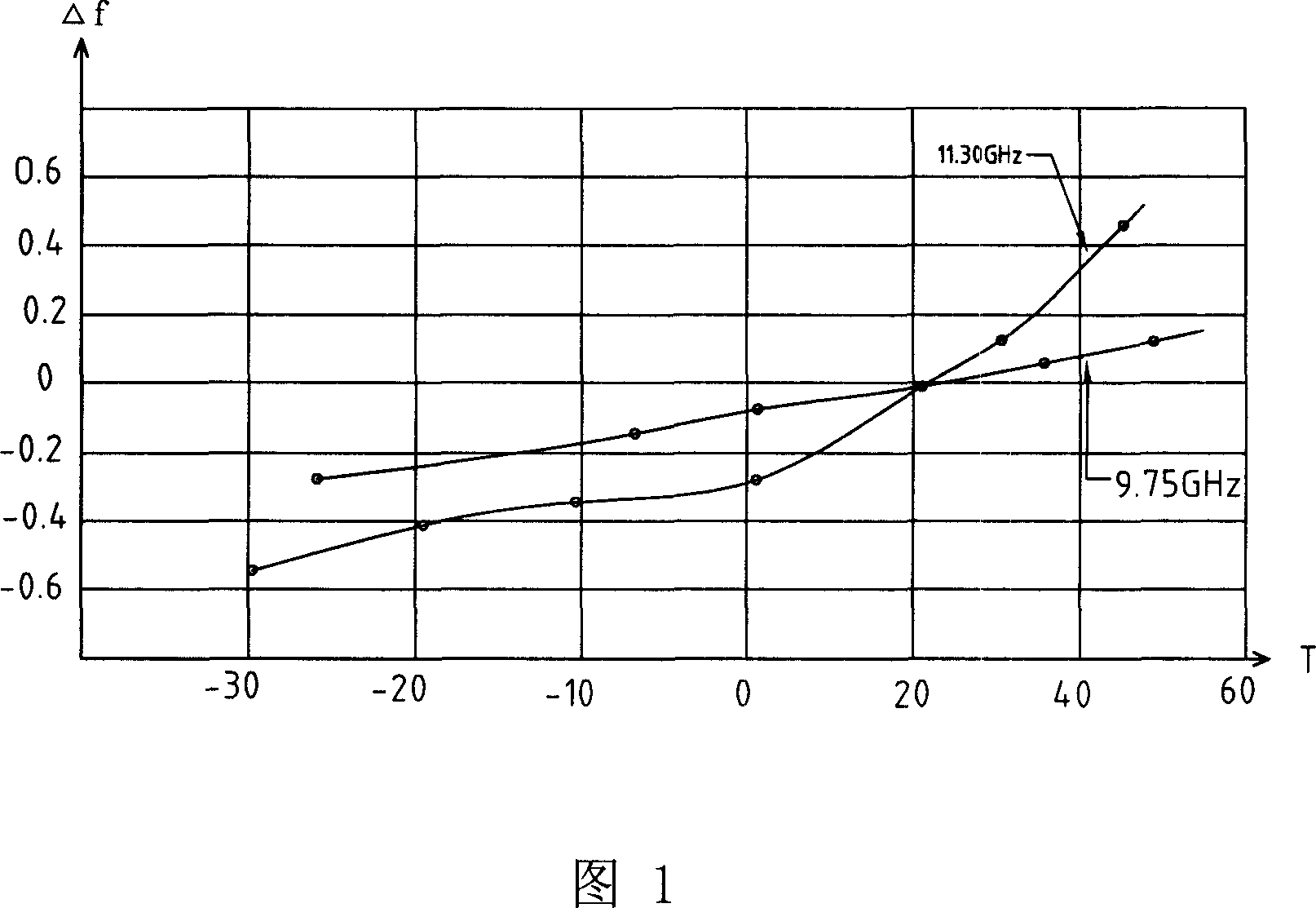

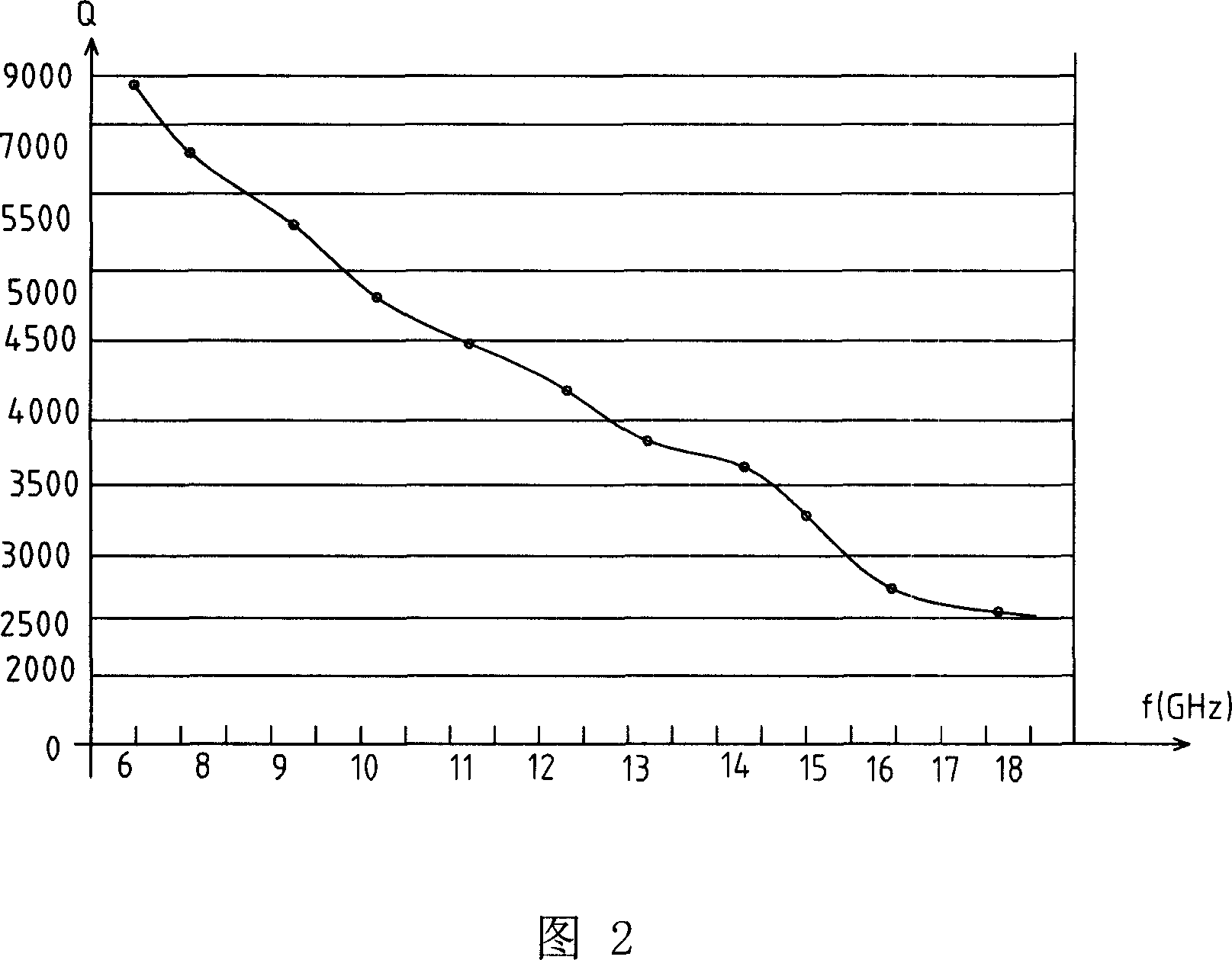

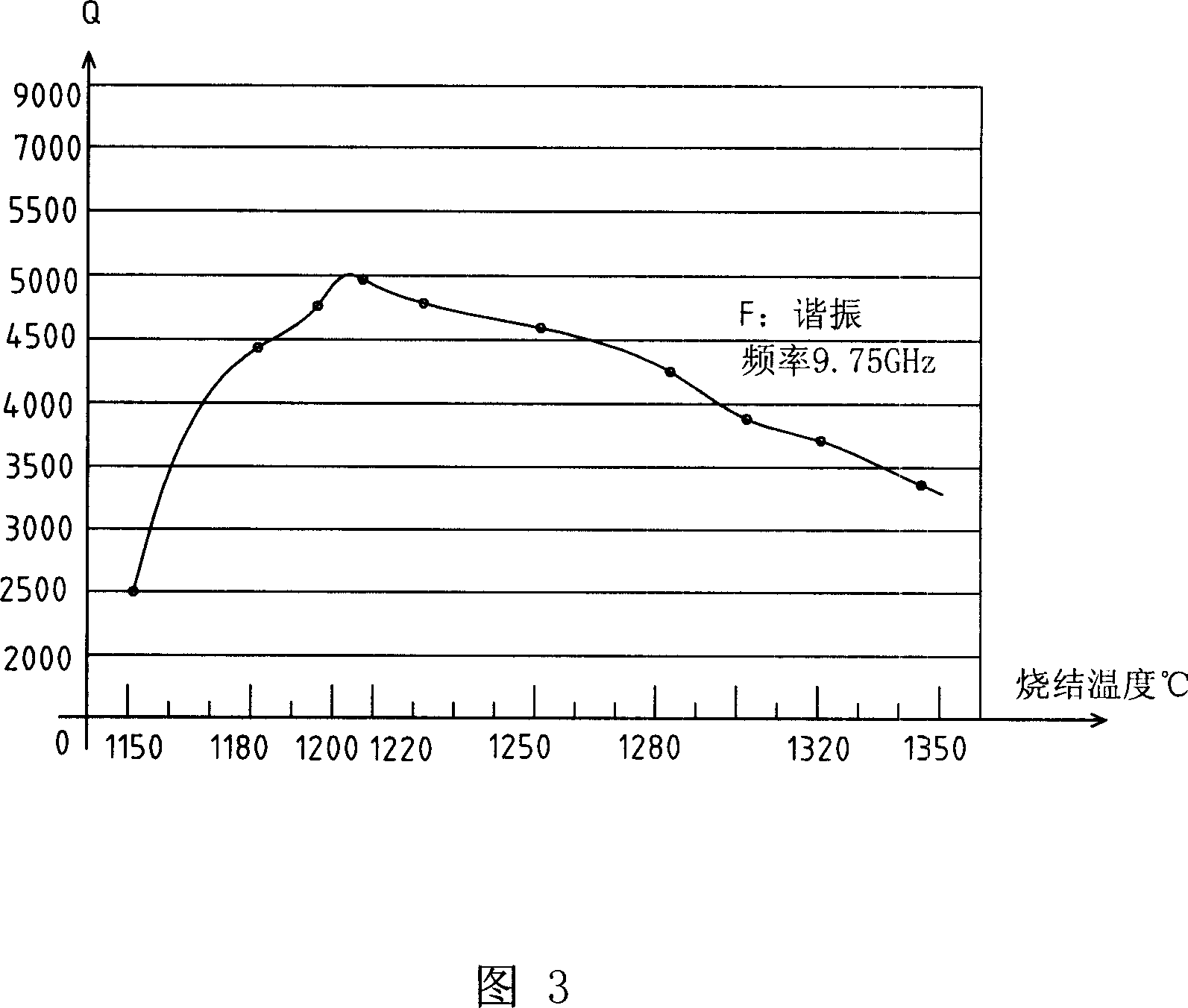

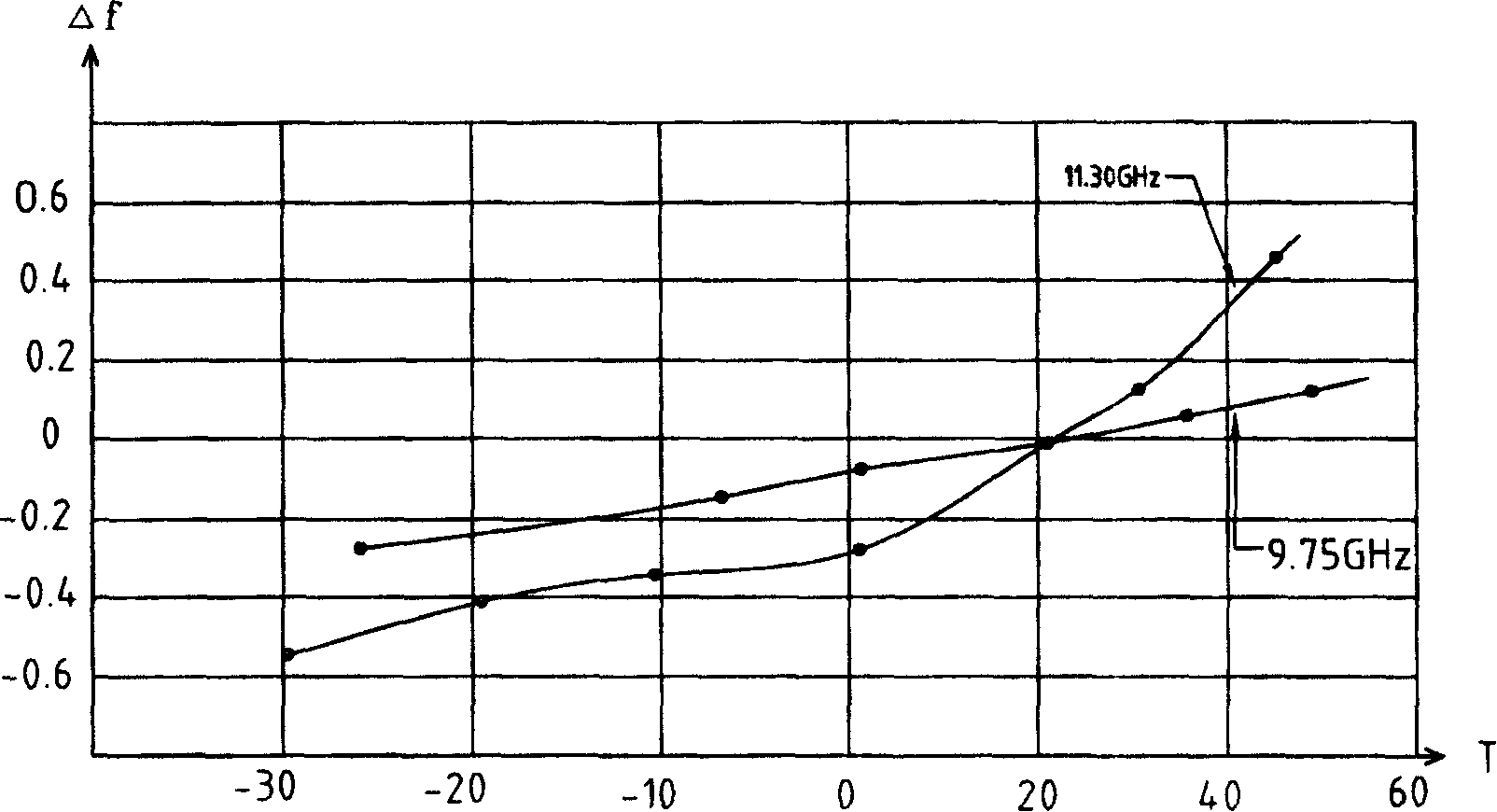

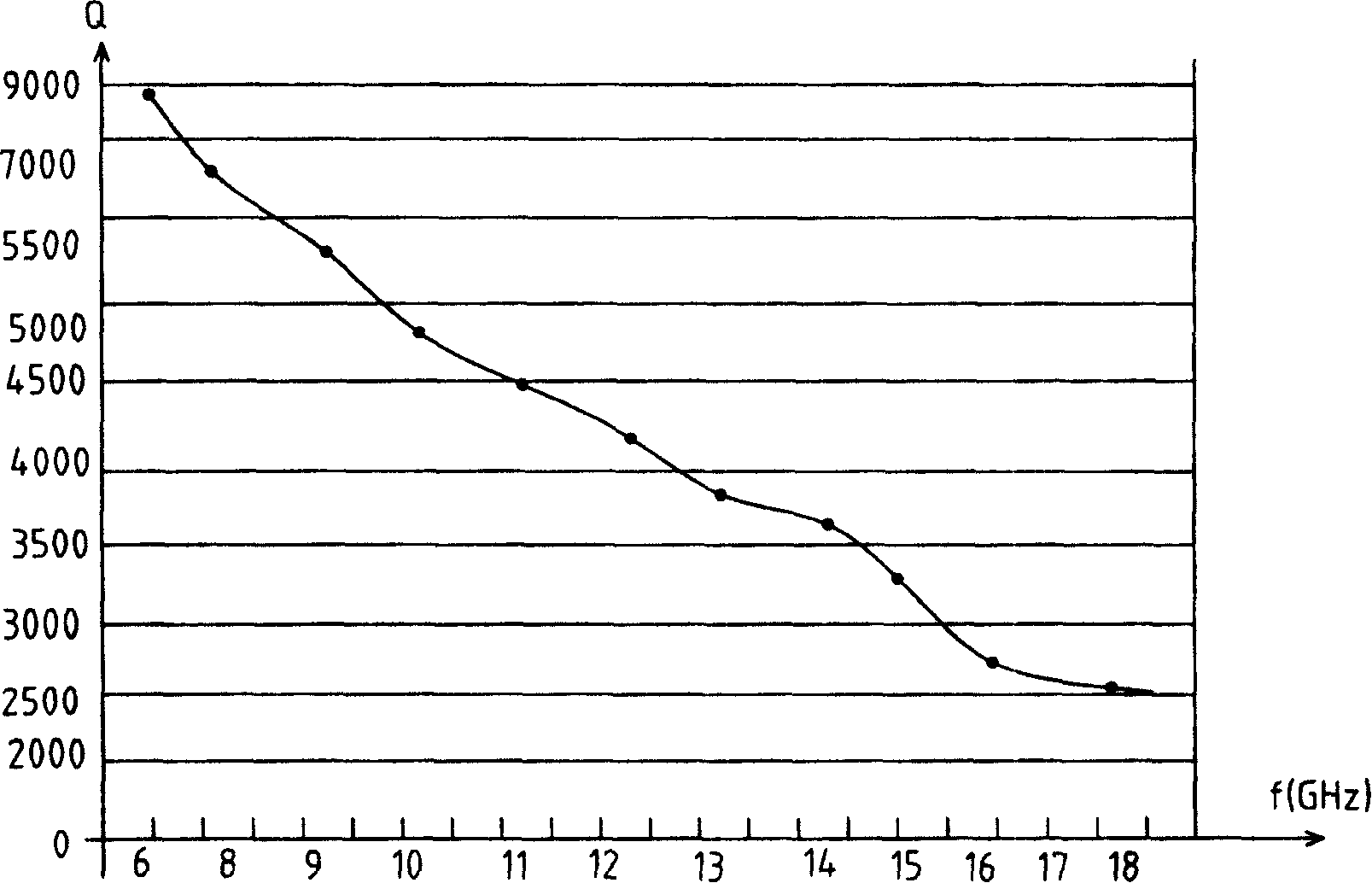

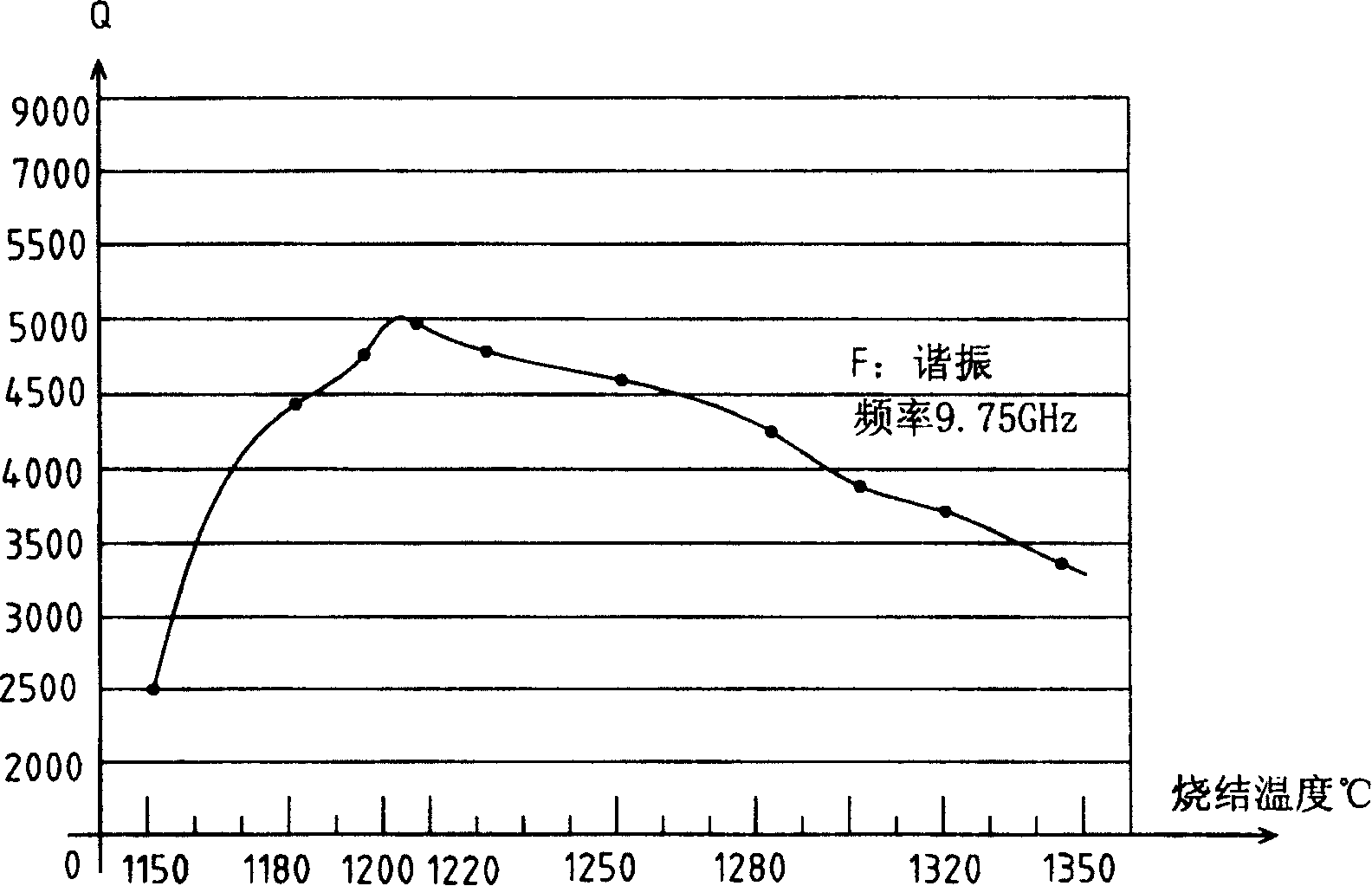

Environment friendly ku band microwave dielectric ceramic

The present invention relates to environment friendly microwave dielectric ceramic for dielectric resonator, filter, vibrator and other microwave elements and devices in Ku band satellite communication system. The microwave dielectric ceramic contains ZrO2, SnO2 and TiO2 as well as micro additives ZnO, La2O3, Co2O3, CuO, SiO2, etc. It is prepared through mixing the materials, ball milling, calcining, crushing, pelletizing, forming, sintering and other steps. It features the low sintering temperature resulting in low power consumption, medium dielectric constant, high quality factor and temperature stable resonant frequency.

Owner:GOSPELL DIGITAL TECH

Non-heat treatment strengthened high-strength and high-toughness die-casting aluminum-magnesium-silicon alloy and preparation method thereof

ActiveCN108754256BImportant industrial application valueMeet application needsSilicon alloyDie casting

Owner:SHANGHAI JIAO TONG UNIV +1

A method of manufacturing a thin film transistor driving backplane

ActiveCN102768992BSimplify the number of masksReduce manufacturing costSemiconductor/solid-state device manufacturingCapacitanceSemiconductor materials

An embodiment of the invention discloses a manufacture method of a thin film transistor driving rear panel. The manufacture method is used for efficiently using a metal-oxide semiconductor material to manufacture the thin film transistor driving rear panel. The embodiment comprises preparing and imaging a metal conducting layer; sequentially depositing insulating films and metallic oxide films on the metal conducting layer to respectively serve as gate insulation layers and active layers; imaging the active layers according to shapes of the metal conducting layer; depositing the insulating films on the active layers to serve as corrosion stopping layers; using a gray level mask plate imaging process, preparing contact holes on the gate insulation layers and imaging the corrosion stopping layers, and defining source and drain electrode area of a thin film transistor and active area of storage capacitance; and depositing and imaging a conductive thin film layer on the corrosion stopping layers.

Owner:GUANG ZHOU NEW VISION OPTO ELECTRONICS TECH

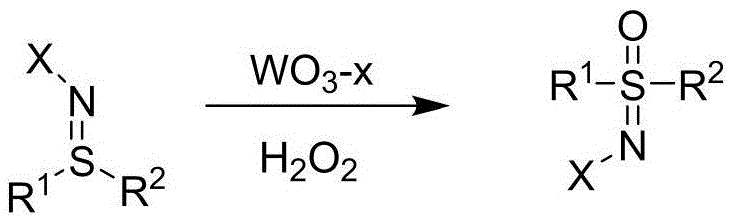

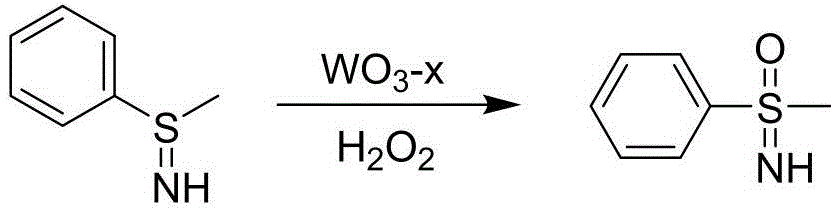

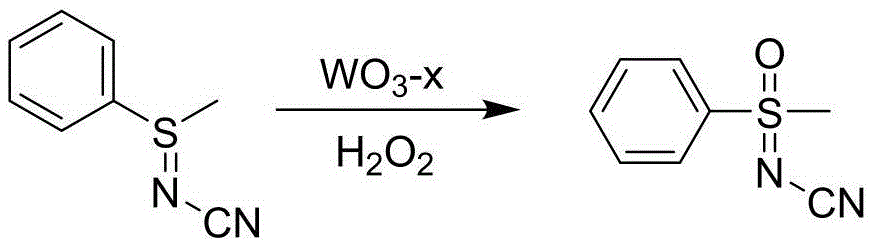

Method for oxidizing sulfilimine into sulfoximide

InactiveCN105481743ASimple reaction conditionsImportant industrial application valueOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsSocial significanceEnvironmental chemistry

The invention provides a method for oxidizing sulfilimine into sulfoximide. The method comprises the following steps: preparing a tungsten oxide WO3-x nanosheet catalyst, and carrying out WO3-x nanosheet catalyzed oxidation of sulfilimine. The method has the advantages of simple reaction conditions, no pollution in the whole reaction steps, low cost, important industrial application values, and important environmental and social significance.

Owner:NANYANG NORMAL UNIV

Production process of flavonoids by liquid-solid two-phase culture of Phellinus japonica

InactiveCN103627728BIncrease productionThe cultivation process is simpleMicroorganism based processesFermentationDouble phaseCulture fluid

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Catalyst for low-temperature water-gas-shift reaction under hydrogenous reformed gas and preparation method thereof

InactiveCN101954279BReduce catalytic activityImprove conversion efficiencyHydrogen separation using solid contactCatalyst activation/preparationActive componentWater-gas shift reaction

The invention relates to a catalyst for a low-temperature water-gas-shift reaction under a hydrogenous reformed gas and a preparation method thereof. The catalyst of the invention comprises the following component in percentage by weight: 0.1 to 3 percent of aurum (Au) and 97 to 99.9 percent of zirconium oxide (ZrO2), wherein the Au is an active component; and the ZrO2 is a carrier. The ZrO2 carrier prepared by the method has larger specific surface area and larger pore volume, so the active component Au can be dispersed better. The catalyst of the invention still has higher low-temperature water-gas-shift catalytic activity under the condition of lower Au mass content, for example, when the Au weight content reduced to 1 percent, the carbon monoxide (CO) conversion rate of the Au / ZrO2 catalyst is still near the balance conversion rate at the temperature of between 210 and 300 DEG C. The catalyst of the invention has the advantages of wide using conditions and particular suitability for a high airspeed hydrogenous reformed gas atmosphere.

Owner:FUZHOU UNIV

High-temperature solid lubricating coating for foil air bearing and preparation method thereof

InactiveCN102021577BWear avoidance or reductionGuaranteed uptimeVacuum evaporation coatingSputtering coatingAir bearingRoom temperature

The invention relates to the field of high-temperature solid lubricating coatings, in particular to the high-temperature solid lubricating coating for a foil air bearing and a preparation method thereof, which solve the problem of abrasion of a foil in the foil air bearing at room temperature to 650 DEG C. The coating adopts a CuAl alloy, and comprises the following chemical components in percentage by weight: 80 to 98 percent of Cu and 2 to 10 percent of Al. The coating is prepared by vacuum arc ion plating technology, and process parameters comprise the arc voltage of 20 to 30V, the arc current of 75 to 95A, the guiding voltage of 12 to 18V, the guiding current of 4 to 7A, the focusing voltage of 9 to 13V and the focusing current of 4 to 8A. The preparation method comprises the following steps of: first performing vacuum arc ion plating under the bias voltage of 500 to 600V for 1.5 to 3.5min; then performing the vacuum arc ion plating under the bias voltage of 200 to 300V for 3 to 4h; and finally obtaining the high-temperature solid lubricating coating. The high-temperature solid lubricating coating provided by the invention can improve the friction and abrasion resistance of a high-temperature solid self-lubricating coating for a shaft and avoid or reduce the abrasion of the foil, thereby ensuring the stable running of the foil air bearing in a high-temperature and high-speed environment.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

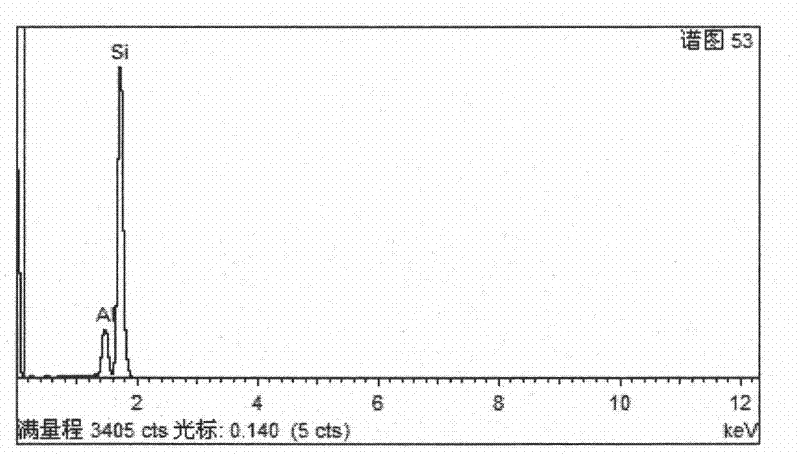

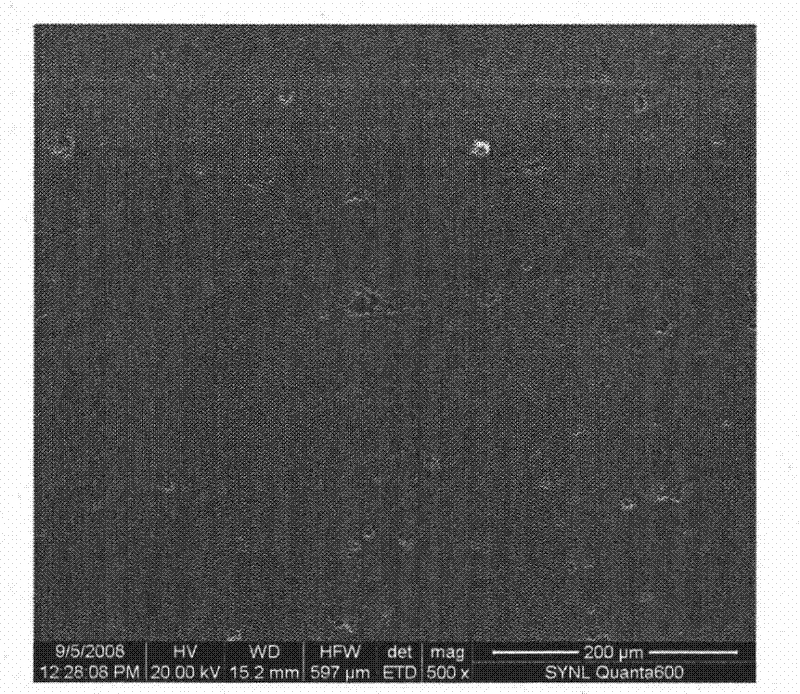

Glass coated target material and preparation method thereof

InactiveCN102021515BImportant industrial application valueMolten spray coatingVacuum evaporation coatingAl powderMetallurgy

The invention relates to the field of preparation of glass coated target materials, in particular to a glass coated target material and a preparation method thereof, which solve the problem of preparation of magnetron sputtering glass coated target materials. The glass coated target material is prepared from SiAl powder serving as a raw material which is prepared by mechanically mixing pure Si powder and pure Al powder, wherein the mixed powder comprises 85 to 95 weight percent of Si powder with particle diameter of between 45 and 125 mu m and 5 to 15 weight percent of Al powder with particlediameter of between 30 and 100 mu m. The glass coated target material is prepared by atmospheric plasma spray coating technology; and the preparation process parameters are that: the current is 400 to 500A, the voltage is 45 to 58V, the powder feed rate is 40 to 60g / minute, the powder feed air flow is 5.0 to 7.0L / minute, the main air flow is 41 to 43L / minute, the main air pressure is 0.45 to 0.55MPa, the secondary air flow is 1.6 to 2.8L / minute, the secondary air pressure is 0.25 to 0.35MPa, the spray coating distance is 100 to 150mm, and the spray coating angle is 75 to 90 degrees. The sputtering cathode target material prepared by the method is suitable for production of coated glass and has great industrial application value.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Chiral resolution method for hydroxy esters

ActiveCN106636293AImportant industrial application valueSolve the disadvantage of poor optical selectivityFermentationChiral resolutionAlpha hydroxy acid

Owner:卓虹超源生物科技(郑州)有限公司

Method for producing polysaccharide by crossly culturing tremella fuciformis basidiospores by stages

InactiveCN102041287BIncrease productionImportant industrial application valueMicroorganism based processesFermentationBiotechnologyBasidiospore

The invention discloses a method for producing polysaccharide by crossly culturing tremella fuciformis basidiospores by stages, comprising the following step that the fermenting and culturing process includes three stages which are respectively carried out on a rotary type swing bed and a reciprocated type swing bed at the same rotation speed for crossly culturing. By applying the method providedby the invention for culturing tremella fuciformis conidiums, tremella fuciformis polysaccharide can be produced in high efficiency, and the output of the polysaccharide can reach 5.80g / L. The method provided by the invention is a production method with favorable industrialized prospect, thereby laying the foundation for producing tremella fuciformis polysaccharide for the industrialized economy.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Environment friendly ku band microwave dielectric ceramic

ActiveCN100408507CComply with strict standardsComply with pollution-free requirementsCeramicsMicrowaveCommunications system

The present invention relates to environment friendly microwave dielectric ceramic for dielectric resonator, filter, vibrator and other microwave elements and devices in Ku band satellite communication system. The microwave dielectric ceramic contains ZrO2, SnO2 and TiO2 as well as micro additives ZnO, La2O3, Co2O3, CuO, SiO2, etc. It is prepared through mixing the materials, ball milling, calcining, crushing, pelletizing, forming, sintering and other steps. It features the low sintering temperature resulting in low power consumption, medium dielectric constant, high quality factor and temperature stable resonant frequency.

Owner:GOSPELL DIGITAL TECH

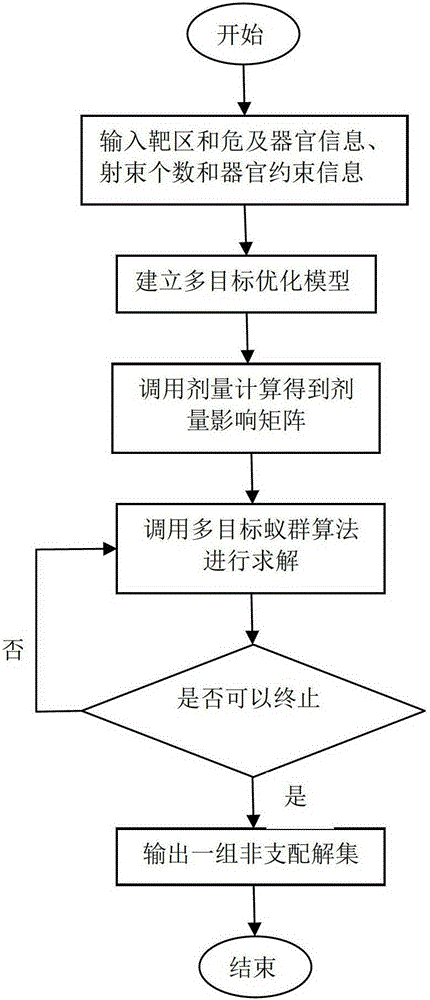

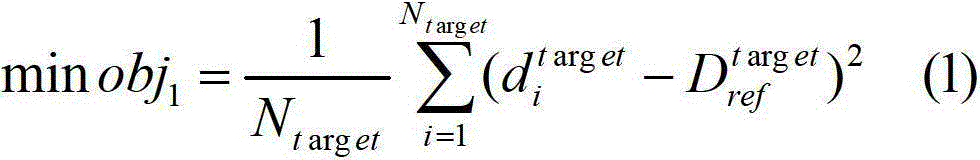

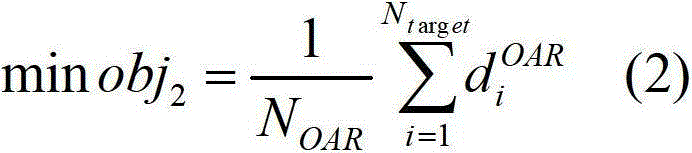

A multi-objective optimization system and method for beam direction based on ant colony algorithm

InactiveCN103143123BImportant industrial application valueSolve technical problemsBiological modelsSpecial data processing applicationsTransfer probabilityMathematical model

The invention provides a system and a method for beam direction multi-target optimization based on an ant colony algorithm. First, a multi-target optimization model is established according to restrictions of a target region, information of organs at risk, beam setting parameters and dose (volume) of each organ, and beam direction searching is performed by adopting fast non-dominated sequencing. Ants search simultaneously, selection is carried out according to state transfer probabilities during searching, pheromone is updated for one time after each patch of ants finish searching, and after all the ants finish searching, one group of non-nominated solution of an optimal beam direction is obtained. The system and the method of beam direction multi-target optimization based on the ant colony algorithm not only accurately establish a mathematic model of an optimization problem, but also are fast in solving speed, stable in algorithm and strong in robustness. A user can select a reasonable solution from a non-nominated solution set.

Owner:合肥克瑞斯信息科技有限公司

High-performance ceramic material and preparation method thereof

InactiveCN109485412AHigh quality factorResonant frequency temperature coefficient adjustableMicrowaveMetal

The invention provides a high-performance ceramic material. The material is prepared from mMO-yLn2O3-zTiO2 and metal nano-grade additives, wherein M includes Ba and one or two of Ca and Sr; Ln includes La and one or more of Sm, Pm, Nd, Pr and Eu; the metal nano-grade additive includes Zn and one or more of Zr, Sn, Mg, Ni, Co and W; and the sum of x, y and z is 1. The invention further provides a preparation method of the ceramic material. The microwave medium ceramic material has a dielectric constant of 46-48, a relatively high quality factor of 35000-50000GHz, and has the resonance frequencytemperature coefficient being adjustable between negative 12-12ppm / DEG C.

Owner:嘉兴实新企业服务有限公司

A self-generated membrane filtration method and filtration device for wastewater treatment

InactiveCN104709969BLow costThe fermentation process is simpleSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisCycloneSelf forming

The invention discloses a self-forming membrane filtering method and device for wastewater treatment. According to the technical scheme, a fixed membrane carrier is arranged in an airtight cylinder; solid suspensions (SS) in wastewater are coagulated into relatively large flocculent particles under the action of a flocculant; the flocculent particles are attached to the cylinder or prism membrane carrier under preset pressure and cyclone action to automatically form a membrane; the wastewater is filtered, and the filtered wastewater is discharged through the self-forming membrane layer. The self-forming membrane filtering device comprises the airtight cylinder, wherein a back-flushing device is arranged at the top of the airtight cylinder; a mud discharging channel is formed in the bottom of the airtight cylinder; a water inlet is arranged in the side near the bottom end of the airtight cylinder; a water outlet is arranged in one side near the top end of the airtight cylinder; the membrane carrier connected respectively with the back-flushing device and the water inlet is arranged in the airtight cylinder; a cyclone pipe communicated with the water inlet is arranged at the bottom end in the airtight cylinder. The method is simple in treatment technology, small in occupied area, low in cost, high in efficiency and great in energy-saving effect.

Owner:LIAONING JIECHEN ENVIRONMENTAL PROTECTION EQUIP CO LTD

Lipase mutant with increased optimum temperature and application of lipase mutant with increased optimum temperature

ActiveCN102994471BOptimum temperature increaseImportant industrial application valueFungiHydrolasesRhizopusMutant

The invention discloses a lipase mutant with increased optimum temperature, which belongs to the technical field of enzymatic genetic engineering. The lipase mutant with increased optimum temperature disclosed by the invention is obtained through taking rhizopus chinensis China center for type culture collection (CCTCC) M201021 lipase as a parent and utilizing a molecular biological technique, and the mutant amino acid of the mutant is Asp310Val. The optimum temperature of the lipase mutant is increased compare with the optimum temperature of the parent of rhizopus chinensis lipase and has an important industrial application value.

Owner:宁夏夏盛实业集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com