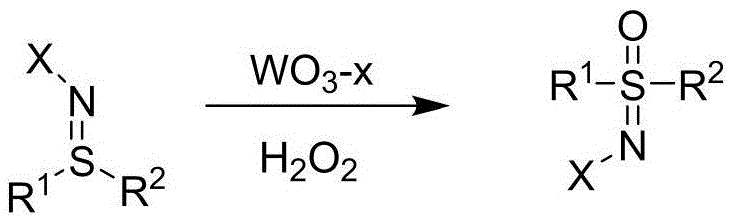

Method for oxidizing sulfilimine into sulfoximide

A technology of sulfimide and sulfonimine, which is applied in the field of sulfimide oxidation to sulfonimine, can solve the problems of unfavorable product purification, easy environmental pollution, oxidizing agent does not meet atomic economy, etc., and achieves important environmental and social significance, The effect of simple reaction conditions and important industrial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Dissolve 1 mmol of sodium tungstate dihydrate in 15 ml of water, stir for 5 minutes, and make a uniform and transparent solution;

[0024] (2) Add 6 milliliters of ethanol to the above solution, stir for 5 minutes;

[0025] (3) Add 15 milliliters of sulfuric acid in above-mentioned solution, stir 5 minutes;

[0026] (4) Add 0.1 gram of polyethylene glycol 10000 to the above solution and stir for 5 minutes;

[0027] (5) Transfer the above mixture into a 100 ml round bottom flask, stir at 120°C for 3 hours, and cool to room temperature;

[0028] (6) Pour the above-mentioned cooled reaction mixture into 500 ml of distilled water, collect the precipitate, wash it with deionized water and absolute ethanol in turn, and dry it in vacuum to obtain the tungsten oxide WO with oxygen holes. 3-x Nanosheets.

Embodiment 2

[0030] (1) Dissolve 2 mmol of sodium tungstate dihydrate in 20 ml of water, stir for 10 minutes, and make a uniform and transparent solution;

[0031] (2) Add 10 milliliters of ethanol to the above solution, stir for 10 minutes;

[0032] (3) Add 20 milliliters of sulfuric acid in above-mentioned solution, stir 10 minutes;

[0033] (4) Add 0.3 grams of polyethylene glycol 10000 to the above solution, and stir for 10 minutes;

[0034] (5) Transfer the above mixture into a 100 ml round bottom flask, stir at 160°C for 4 hours, and cool to room temperature;

[0035] (6) Pour the above-mentioned cooled reaction mixture into 500 ml of distilled water, collect the precipitate, wash it with deionized water and absolute ethanol in turn, and dry it in vacuum to obtain the tungsten oxide WO with oxygen holes. 3-x Nanosheets.

Embodiment 3

[0037] (1) Dissolve 3 millimoles of sodium tungstate dihydrate in 25 milliliters of water, stir for 20 minutes, and make a uniform and transparent solution;

[0038] (2) Add 13 milliliters of ethanol to the above solution, and stir for 20 minutes;

[0039] (3) Add 25 milliliters of sulfuric acid in above-mentioned solution, stir 20 minutes;

[0040] (4) Add 0.6 grams of polyethylene glycol 10000 to the above solution, and stir for 20 minutes;

[0041] (5) Transfer the above mixture into a 100 ml round bottom flask, stir at 200°C for 5 hours, and cool to room temperature;

[0042] (6) Pour the above-mentioned cooled reaction mixture into 500 ml of distilled water, collect the precipitate, wash it with deionized water and absolute ethanol in turn, and dry it in vacuum to obtain the tungsten oxide WO with oxygen holes. 3-x Nanosheets.

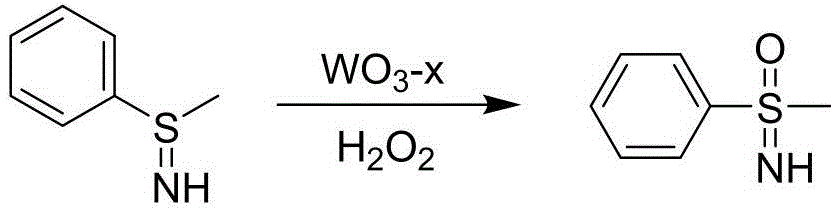

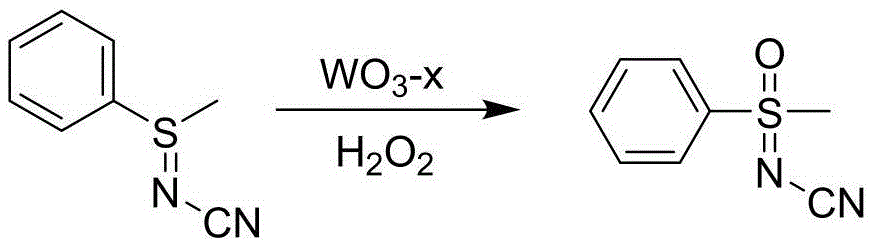

[0043] The preparation embodiment of sulfoximine is as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com