Glass coated target material and preparation method thereof

A technology of target material and glass, which is applied in the field of glass coating target material and its preparation, and achieves the effect of important industrial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of the glass coating target material of the present invention, concrete steps are as follows:

[0020] Step 1: Prepare the SiAl powder by mechanical mixing method according to the planned proportion, and the mixing time is 6 hours.

[0021] Step 2: Preparing the sputtering cathode target by atmospheric pressure plasma spraying technology.

[0022] Step 3: Use a magnifying glass to observe the appearance of the coating prepared in step 2.

[0023] Step 4: Using an infrared thickness tester to measure the thickness of the coating prepared in Step 2.

[0024] Step 5: Density measurement of the coating prepared in Step 2 using the buoyancy method.

[0025] Step 6: Test the oxygen content of the coating prepared in step 2 by chemical analysis.

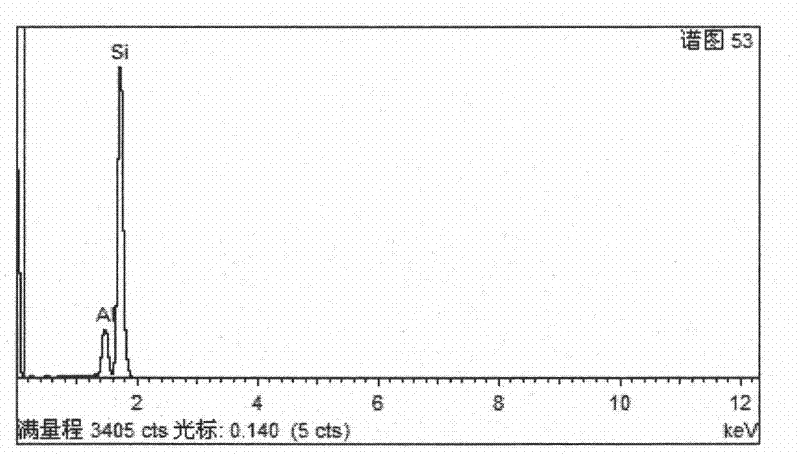

[0026] Step 7: Using a scanning electron microscope to observe the structure and composition of the coating prepared in step 2.

[0027] Step 8: Using a metallographic analysis system to measure the porosit...

Embodiment 1

[0029] In this embodiment, the preparation method of the glass coating target material, the specific steps are as follows:

[0030] Step 1: According to the mass percentage and particle size of each component shown in Table 3, SiAl powder was prepared by mechanical mixing method, and the mixing time was 6 hours.

[0031] Table 3 Mass percentage and particle size of each component in SiAl powder

[0032] Component name

Si

Al

Content (wt%)

90

10

Particle size (μm)

45-125

30-100

[0033] Step 2: Prepare the sputtering cathode target by atmospheric pressure plasma spraying technology, and the preparation process is shown in Table 4.

[0034] Table 4 SiAl target preparation process

[0035]

Process parameters

/ A

/ V

Feeding volume

/ g·min -1

Powder feeding air flow

/ L·min -1

Main air flow

/ L·min -1

pa...

Embodiment 2

[0043] In this embodiment, the preparation method of the glass coating target material, the specific steps are as follows:

[0044] Step 1: According to the mass percentage and particle size of each component shown in Table 5, SiAl powder was prepared by mechanical mixing method, and the mixing time was 6 hours.

[0045] Table 5 Mass percentage and particle size of each component in SiAl powder

[0046] Component name

Si

Al

Content (wt%)

95

5

Particle size (μm)

45-125

30-100

[0047] Step 2: Prepare the sputtering cathode target by atmospheric pressure plasma spraying technology, and the preparation process is shown in Table 6.

[0048] Table 6 SiAl target preparation process

[0049]

Process parameters

/ A

/ V

Feeding volume

/ g·min -1

Powder feeding air flow

/ L·min -1

Main air flow

/ L·min -1

par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com