Self-forming membrane filtering method and device for wastewater treatment

A filtration method and wastewater treatment technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems affecting application, excessive fouling, membrane wear and tear and replacement High cost and other problems, to achieve the effect of simple and reasonable device structure, low investment cost and good energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

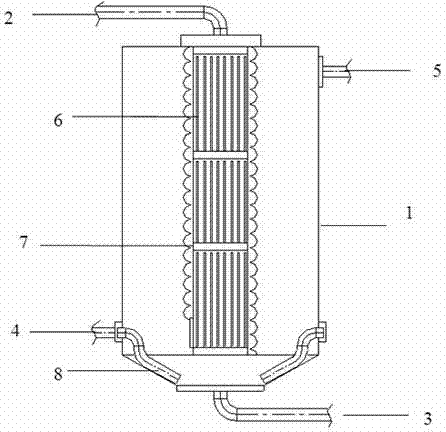

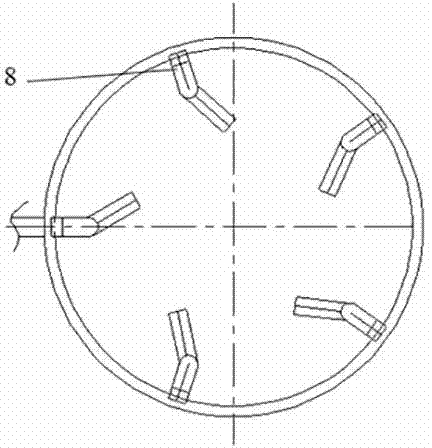

[0030] The present invention utilizes the suspended solids (SS) in the waste water in a closed cylinder to agglomerate the suspended solids (SS) in the waste water into larger flocculent particles with the help of flocculants. Next, let it attach to the membrane frame of cylinder or prism to build a membrane by itself. This membrane is called self-generated membrane or self-built membrane. Wastewater is filtered and clarified through the self-generated membrane; specific filtration methods include:

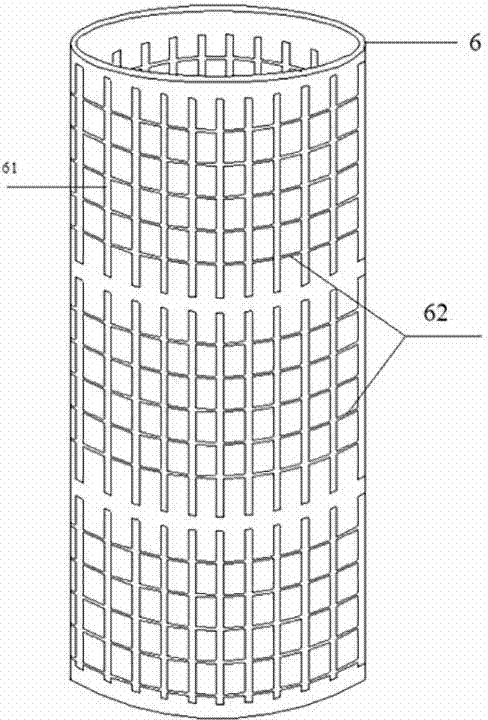

[0031] The first step is to set the supporting formwork in the closed cylinder: the function of the formwork is to provide support for the attachment and formation of the self-generated film, and at the same time as a clear water diversion chamber; the shape of the formwork is a cylinder or a prism, which is The core components of self-modeling can be formed by engineering plastics or metals, or assembled by laminations; the surface of the one-time formed formwork is designed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com