Rigid connection node of fabricated concrete shear wall and floor support plate and construction method

A technology of concrete shear wall and rigid connection, which is applied to floors, building components, buildings, etc., can solve the problems of complex node connection forms and difficult connections, and achieve the effects of simplifying construction procedures, improving construction speed, and positioning accurate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

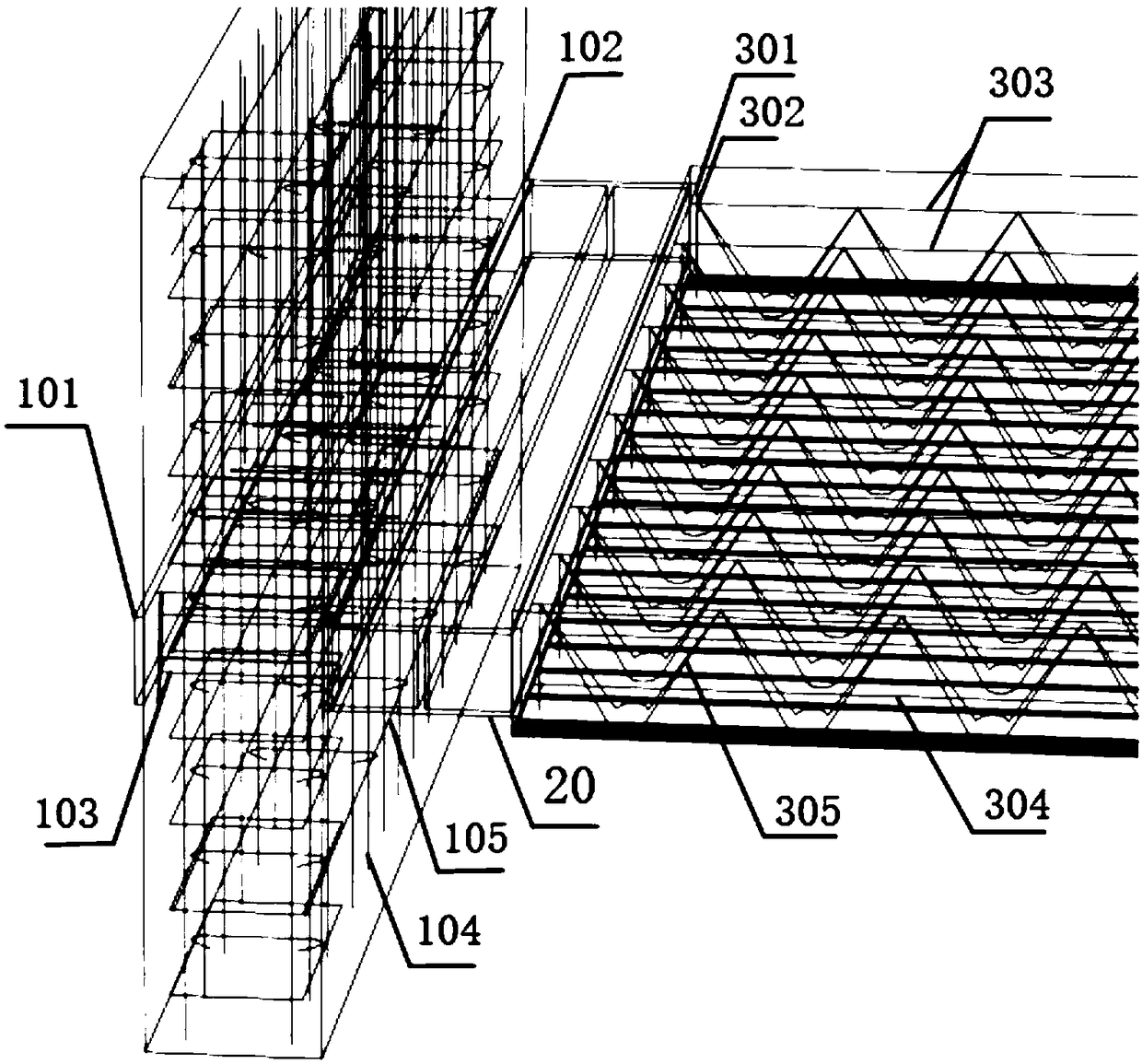

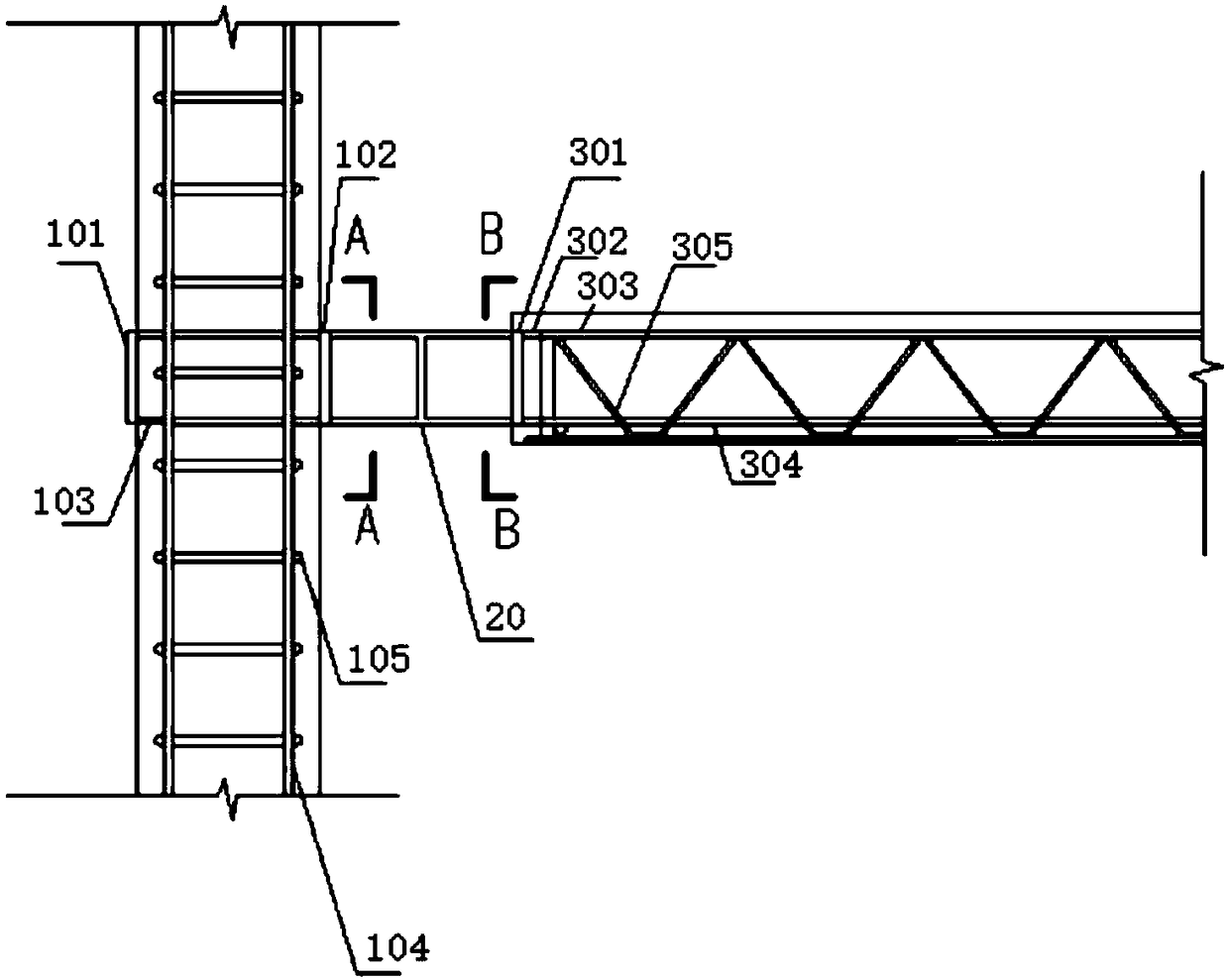

[0040] The following will combine Figure 1 to Figure 5 Describe in detail the rigid connection nodes between the prefabricated concrete shear wall and the floor deck provided by the present invention. This embodiment is implemented on the premise of the technical solution of the present invention, and the detailed implementation and specific operation process are given. However, the scope of protection of the present invention is not limited to the following embodiments, and those skilled in the art can modify and embellish it within the scope of not changing the spirit and content of the present invention.

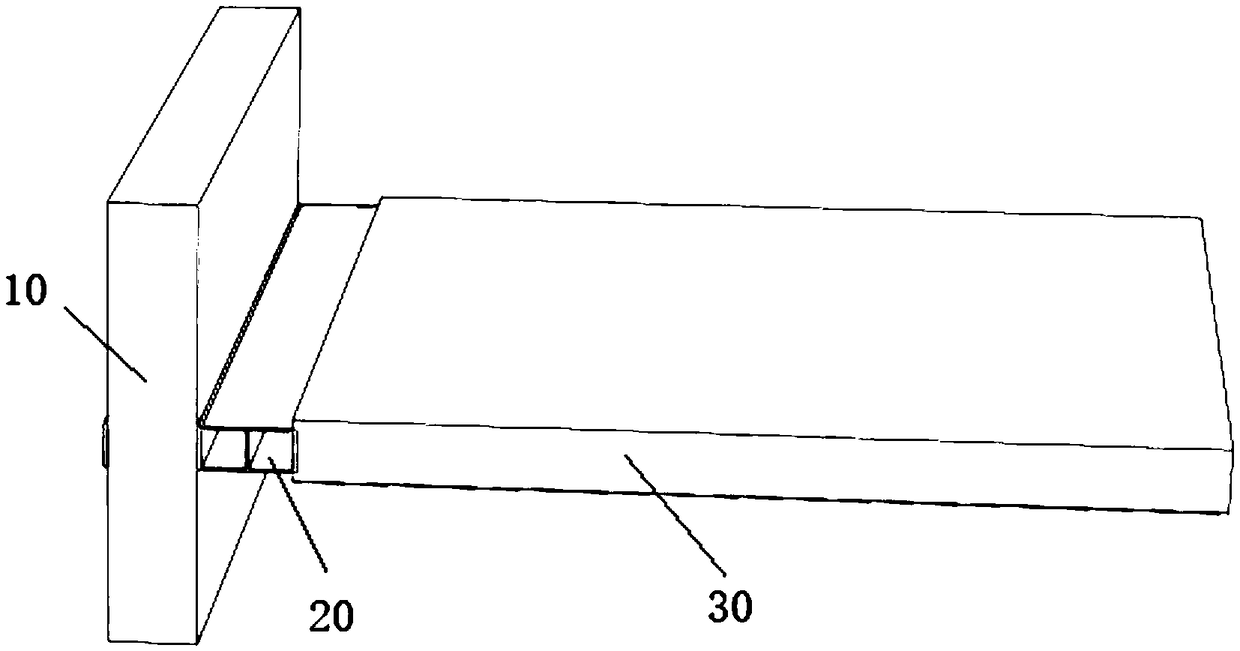

[0041] Please refer to Figure 1 to Figure 5 , a rigid connection node between a prefabricated concrete shear wall and a floor deck, including a concrete shear wall 10 and a concrete floor deck 30, and the floor deck 30 is fixedly connected to one side of the shear wall 10 through H-shaped steel 20 .

[0042] In the present invention, the end of the floor deck 30 can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com